Manufacturing method of PCB equilateral triangle

An equilateral triangle and manufacturing method technology, which is applied in chemical/electrolytic methods to remove conductive materials, printed circuit manufacturing, computer design circuits, etc. Avoid abnormal appearance and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: such as Figure 1-5 Shown, a kind of manufacturing method of PCB equilateral triangle comprises the following steps:

[0032] Step 1: Cutting and baking: Cut the PCB into a certain size and bake it in an oven; the purpose of cutting is to facilitate subsequent equipment processing; the baking conditions are: temperature 122-148°C, The baking time is 2-4h; the substrate is baked to eliminate the stress of the substrate to prevent the substrate from warping, improve the dimensional stability of the substrate, and reduce the expansion and contraction of the substrate;

[0033] Step 2: Drilling: Use a drilling machine to drill multiple positioning holes on the PCB;

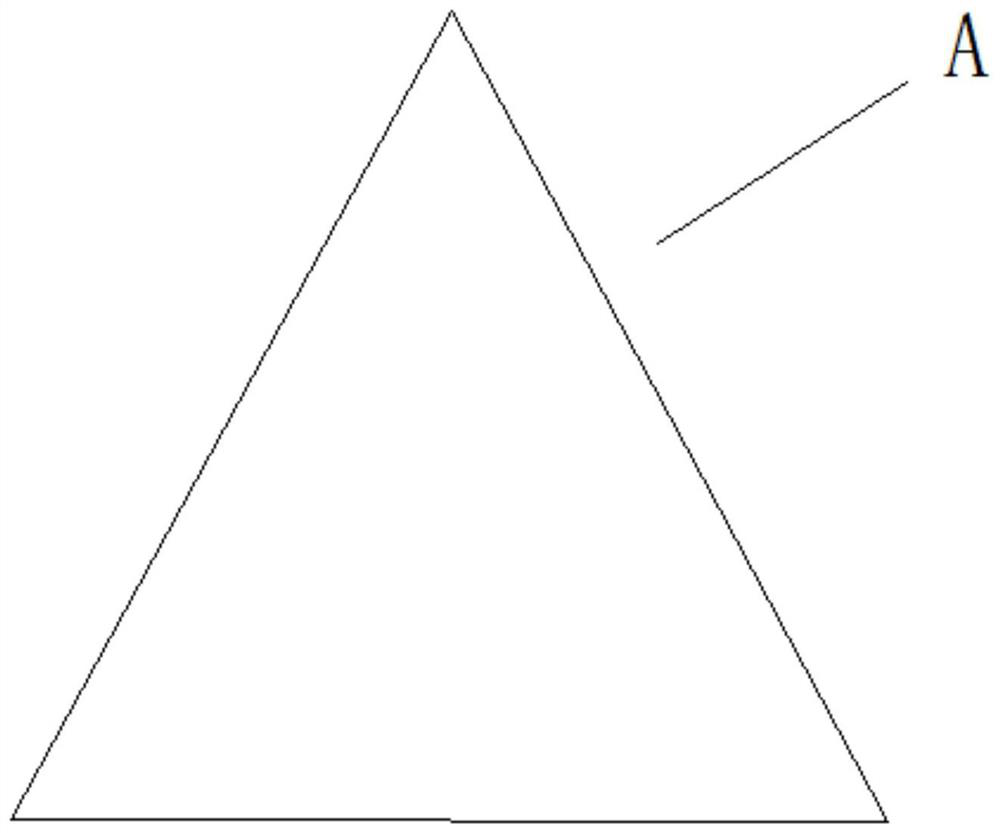

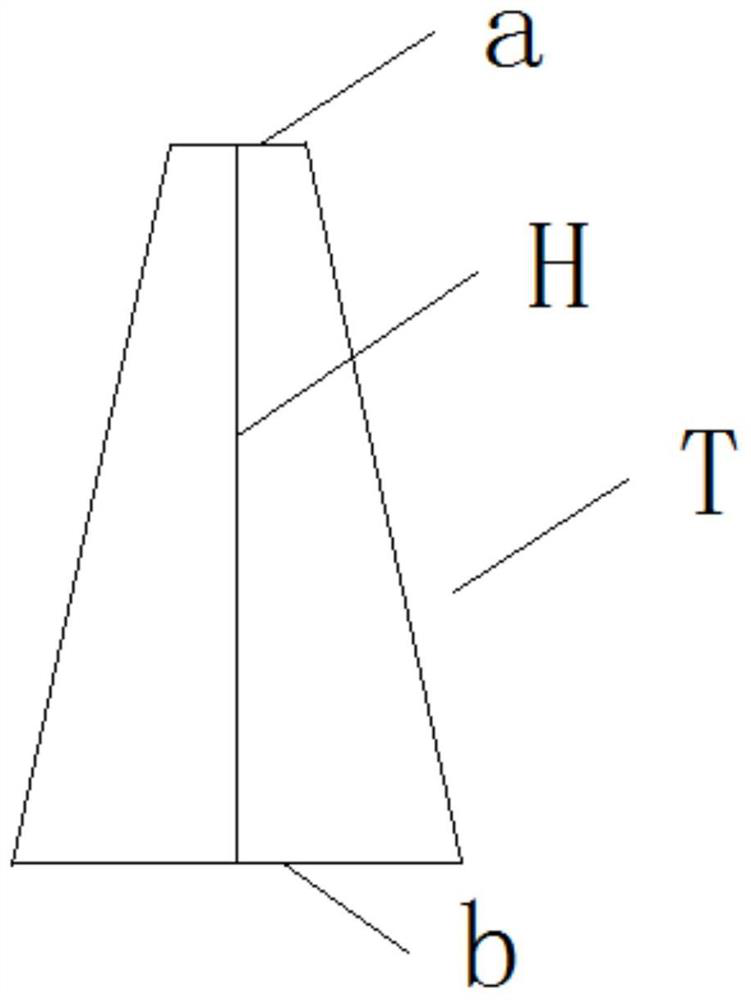

[0034] Step 3: graphic design: according to the design standard, use software to draw an equilateral triangle A (such as figure 2 shown) and isosceles trapezoidal T (such as image 3 shown), and form a new design graphic B (such as Figure 4 shown), the new design figure is composed of the equilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com