Multilateral double-layer bending machine suitable for production of metal protective shell of communication equipment

A technology for communication equipment and protective shells, which is applied in the field of multilateral double-layer bending machines for the production of metal protective shells, can solve the problems that the production and processing requirements of factory equipment cannot be met and the production cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

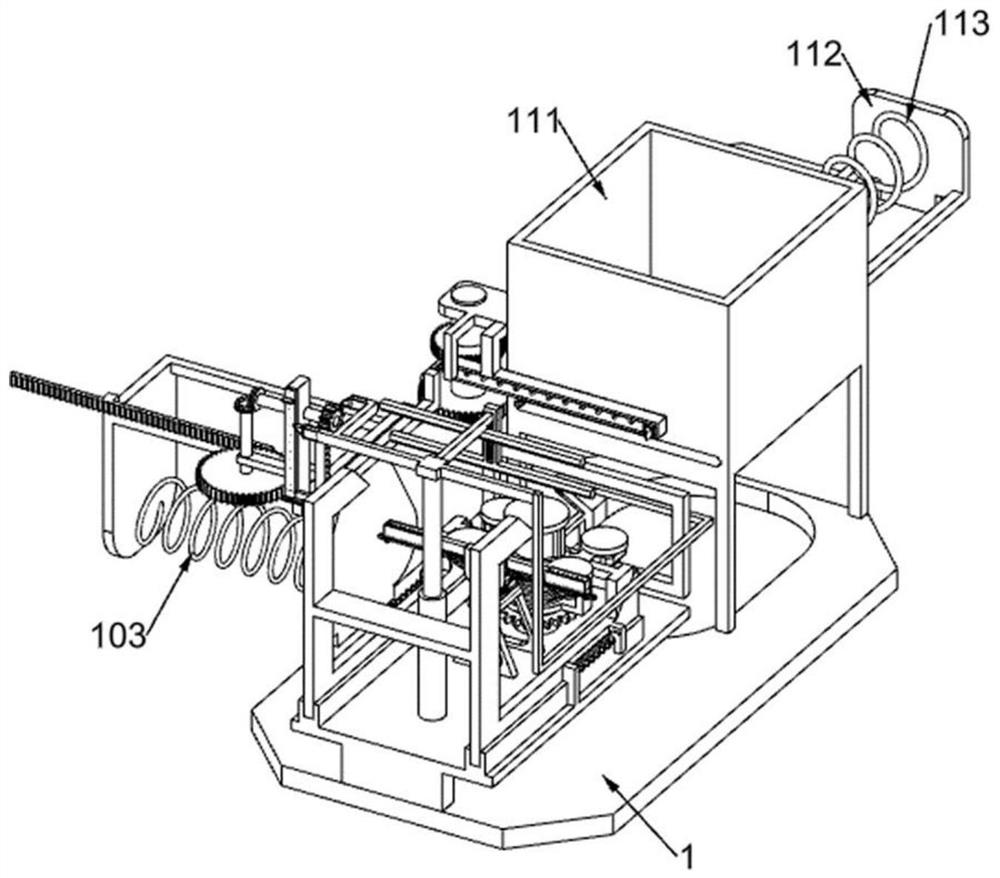

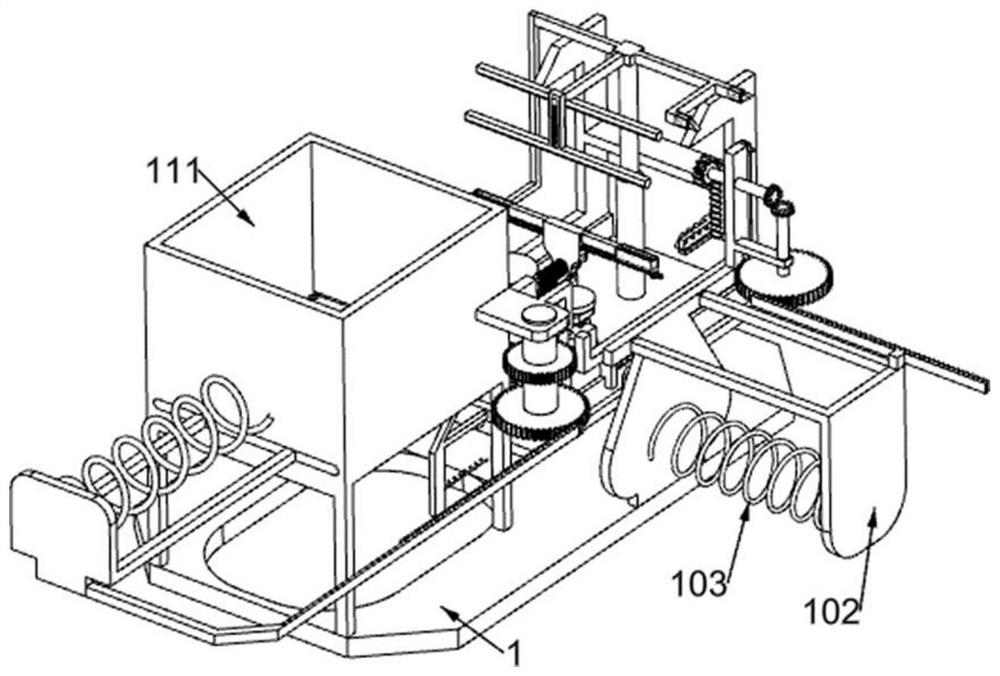

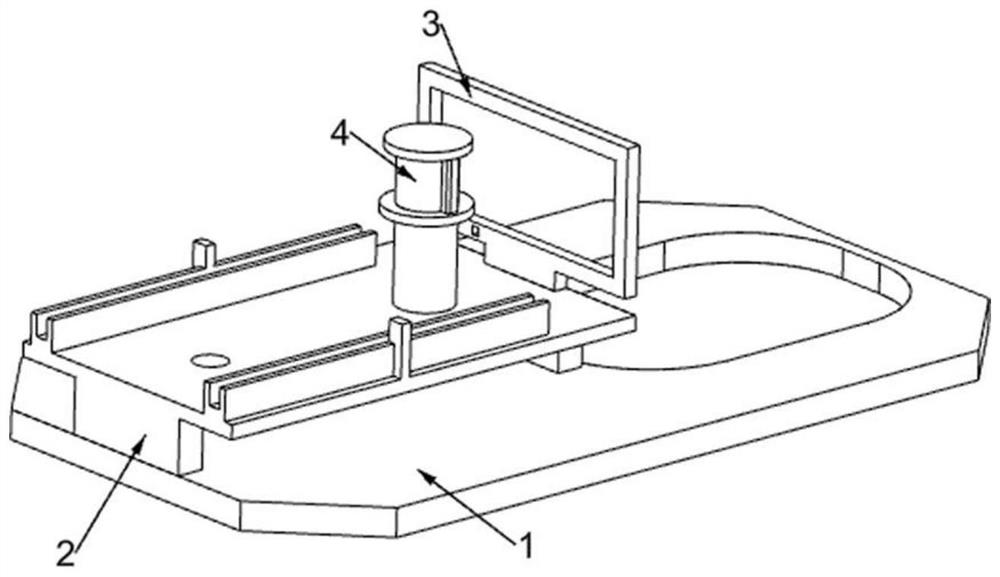

[0043] A multilateral double-layer bending machine suitable for the production of metal protective shells for communication equipment, such as Figure 1-7 As shown, it includes a base plate 1, a slotted slide rail frame 2, a rectangular slotted frame 3, a spline support shaft 4, an adjustment assembly 5 and a bending assembly 6, and the slotted slide rail frame 2 is fixedly installed on the top surface of the bottom plate 1, A rectangular slotted frame 3 is fixedly installed on the slotted slide rail frame 2, and the rectangular slotted frame 3 is used to support the unfolded metal protective case. The spline support shaft 4 is rotatably connected to the slotted slide rail frame 2, and An adjustment assembly 5 is fixedly installed on the grooved slide rail frame 2 , and a bending assembly 6 is also fixedly installed on the slotted slide rail frame 2 .

[0044] The adjustment assembly 5 includes a slotted support seat 51, a screw mandrel one 52, a perforated sliding block 53, a...

Embodiment 2

[0049] On the basis of Example 1, such as Figure 8-11 As shown, it also includes a fixing assembly 7, which is slidably connected to the slotted slide rail frame 2. The fixing assembly 7 is used to fix the metal protective case. The fixing assembly 7 includes a double-sided wedge frame 71, a fifth Back-moving spring 72, four-corner sliding frame 73, magnetic disk 74, the 6th back-moving spring 75, limit frame 76 and the 7th back-moving spring 77, sliding type is connected with double-sided wedge-shaped frame 71 on the grooved slide rail frame 2, double-sided wedge-shaped frame 71 is fixedly connected with a pair of the fifth return spring 72, one end of the fifth return spring 72 away from the double-sided wedge frame 71 is fixedly connected with the slotted slide rail frame 2, and the spline support shaft 4 is slidably connected with a four-corner slide frame 73, The four-corner sliding frame 73 and the double-sided wedge frame 71 are in contact with each other. The four-cor...

Embodiment 3

[0052] On the basis of Example 2, such as Figure 10 As shown, it also includes a rotating assembly 8, which is slidably connected to the rectangular slotted frame 3. The rotating assembly 8 is used to rotate the metal protective case. The rotating assembly 8 includes a special-shaped pressing rod 81, a wedge-shaped rack frame 82 , the eighth back-moving spring 83, rotating gear 84 and overrunning clutch 85, one end of the lower pressure frame 62 is welded with a special-shaped pressing rod 81, and the rectangular slotted frame 3 is slidably connected with a wedge-shaped rack frame 82, and the special-shaped pressing rod 81 and The wedge-shaped rack frame 82 is in contact with each other, and the wedge-shaped rack frame 82 is used to promote the rotation of the rotating gear 84 and its upper device. 83 one end links to each other with slotted slide rail frame 2, is provided with overrunning clutch 85 on the spline support shaft 4, is affixed with rotating gear 84 on the overru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com