Automatic hook sealing and unhooking control method for crane

A control method and crane technology, applied in the directions of load hanging elements, transportation and packaging, safety devices, etc., can solve the problems of cumbersome operation process, damage to hook fixing devices, long time consumption, etc., to ensure safety, avoid excessive relaxation or Tight, fast tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

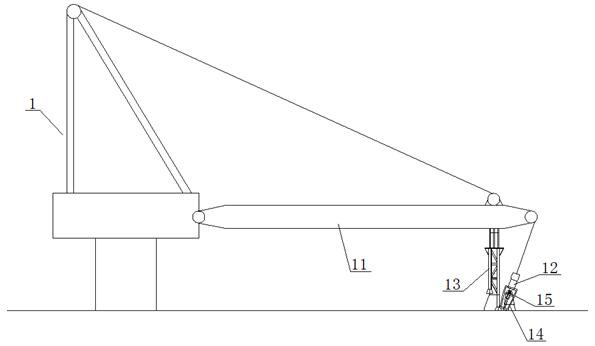

[0039] see figure 1 , figure 2 , a crane automatic hook sealing and unhook control method, the automatic hook sealing and unhook control method is implemented based on the automatic hook sealing and unhook control system 2 carried on the crane 1;

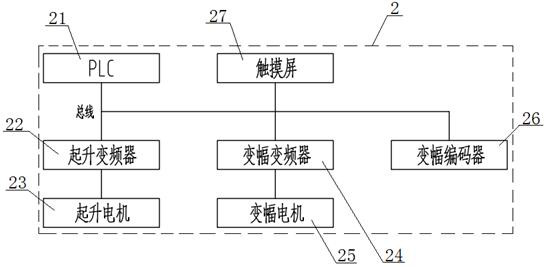

[0040] The automatic locking and uncoupling control system 2 includes a PLC control cabinet 21, a lifting frequency converter 22, a lifting motor 23, a luffing frequency converter 24, a luffing motor 25, a luffing encoder 26, a touch screen 27, the PLC The control cabinet 21, the lifting frequency converter 22, the luffing frequency converter 24, the luffing encoder 26, and the touch screen 27 are signal-connected. Amplitude motor 25 signal connection, described hoisting motor 23, luffing motor 25 are used to drive hoisting winch, luffing winch respectively, and described touch screen 27 is used for switching the control mode of PLC control cabinet 21;

[0041] The automatic hook sealing and unhook control method includes automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com