Novel prefabricated assembled pier connecting structure and construction method thereof

A technology for prefabricated assembling and connecting structures, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of uncontrolled pier swinging, overturning and collapse, unfavorable on-site construction replacement, etc., to achieve balanced force, speed up construction progress, and take into account The effect of practical rationality and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

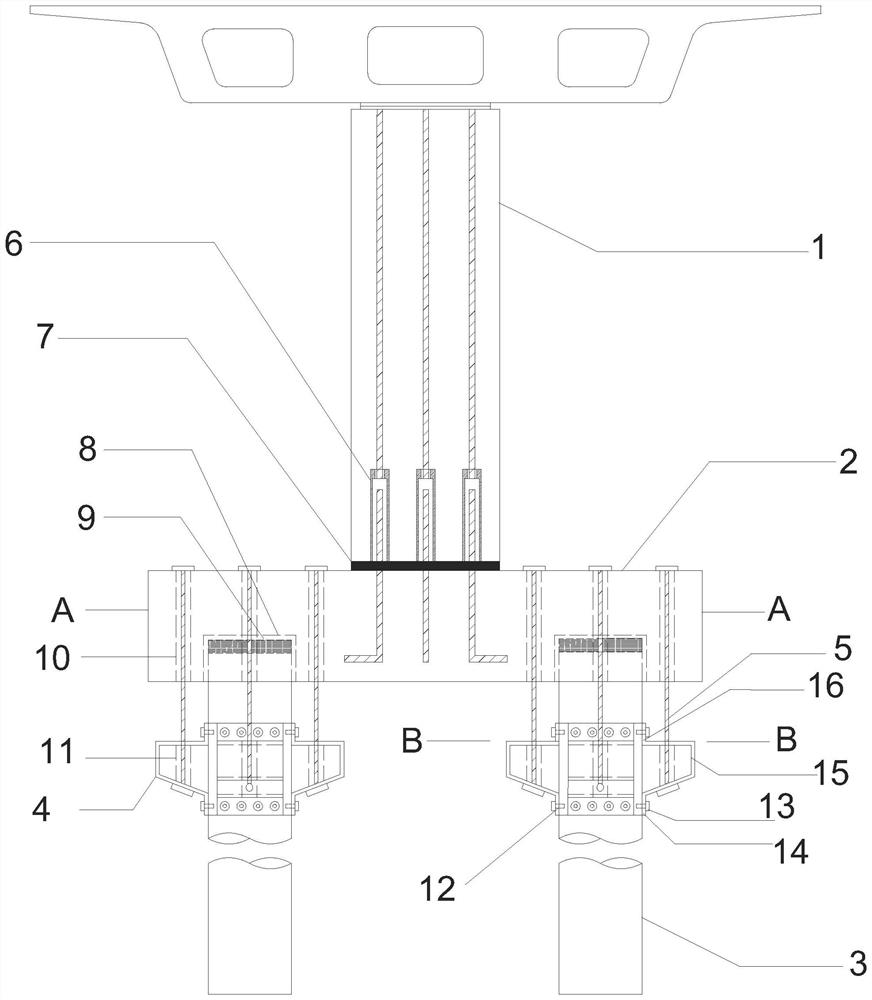

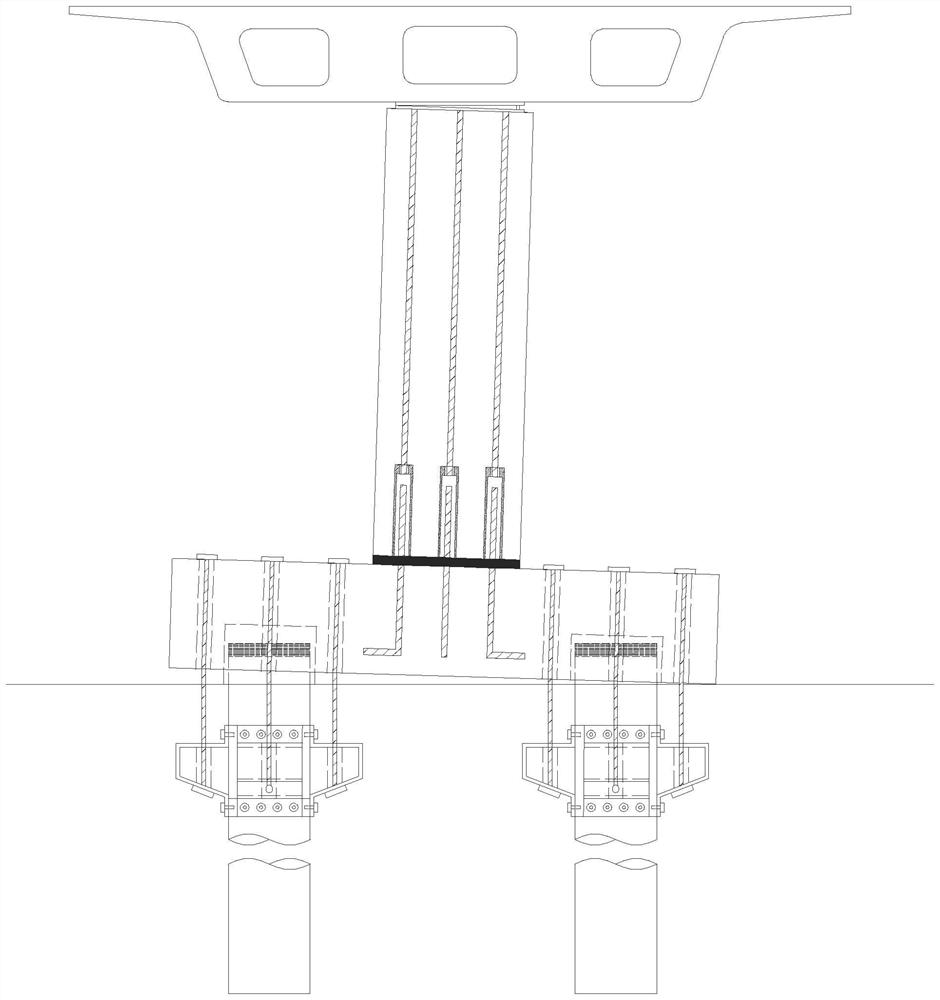

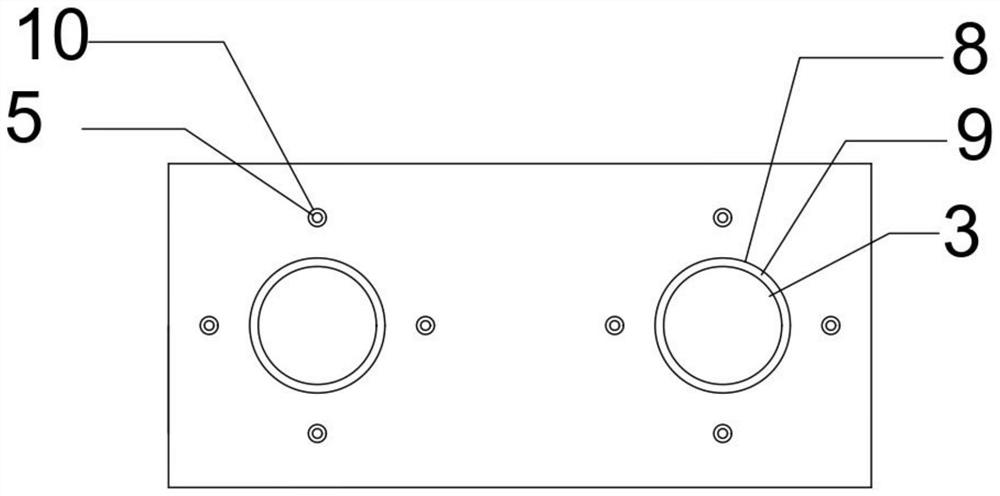

[0034] like figure 1 As shown, a novel prefabricated assembled pier connection structure and construction method thereof, the main structure of the invention includes: assembled pier 1, cap 2, concrete pile 3, steel corbel structure 4; The reserved groove 8 connected with the concrete pile 3, the first prestressed pre-embedded pipe 10 is reserved inside the cap 2, the concrete pile 3 is provided with a steel corbel structure 4, and the steel corbel structure 4 is reserved inside There is a second prestressed pre-embedded pipeline 11, and unbonded prestressed tendons 5 for connecting the bearing platform 2 and the steel corbel structure 4.

[0035] like figure 1 and figure 2 As shown, the assembled pier 1 is connected to the cap 2 through a semi-grouting sleeve 6, and a high-strength mortar seat layer 7 is provided at the bottom of the assembled pier 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com