Pile driver for hook plate pile

A technology of pile driver and hook plate, which is applied to sheet pile walls, cleaning methods using tools, cleaning methods and appliances, etc., can solve the problems of reducing the working efficiency of pile drivers, cumbersomeness, and poor limit effect of hook sheet piles, etc., to achieve The effect of improving usability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

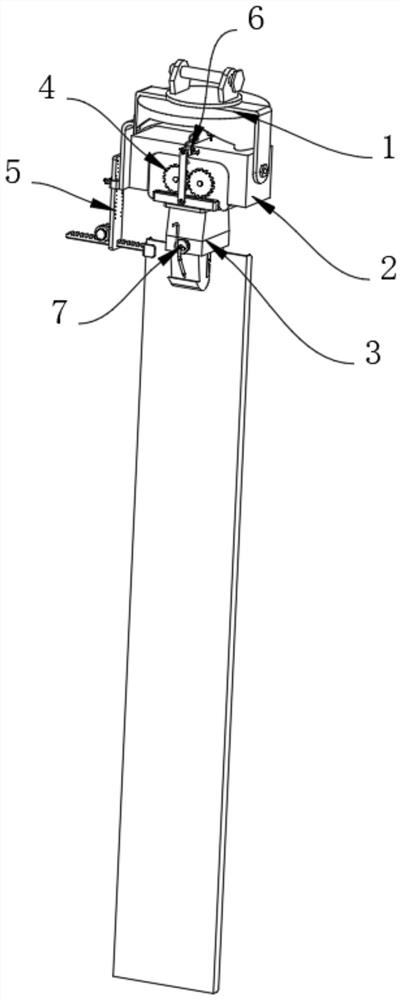

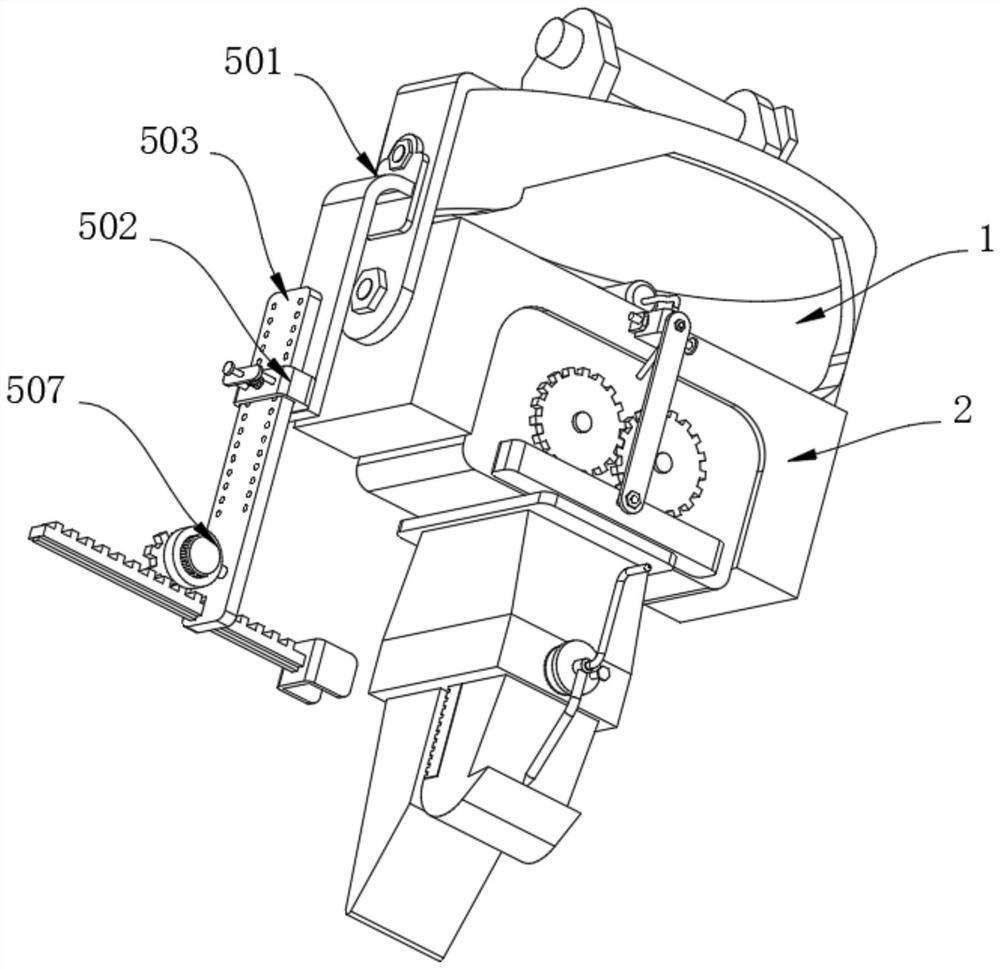

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides a pile driver for a hook pile, including a hanger 1 and a limiting structure 5, and the lower end of the hanger 1 is rotated and mounted, and the lower end of the driver 2 is mounted with a holder 3, The surface of the driver 2 is mounted with two drive wheels 4, and the two drive wheels 4 mesh each other, the surface of the hanger 1 is provided with a limiting structure 5, and the surface of the driver 2 is provided with a lubricating structure 6, and the surface of the holder 3 is provided. Clean up structure 7.

[0031] The specific setting and action of its limit structure 5, the lubricating structure 6, and the cleaning structure 7 is specifically described below.

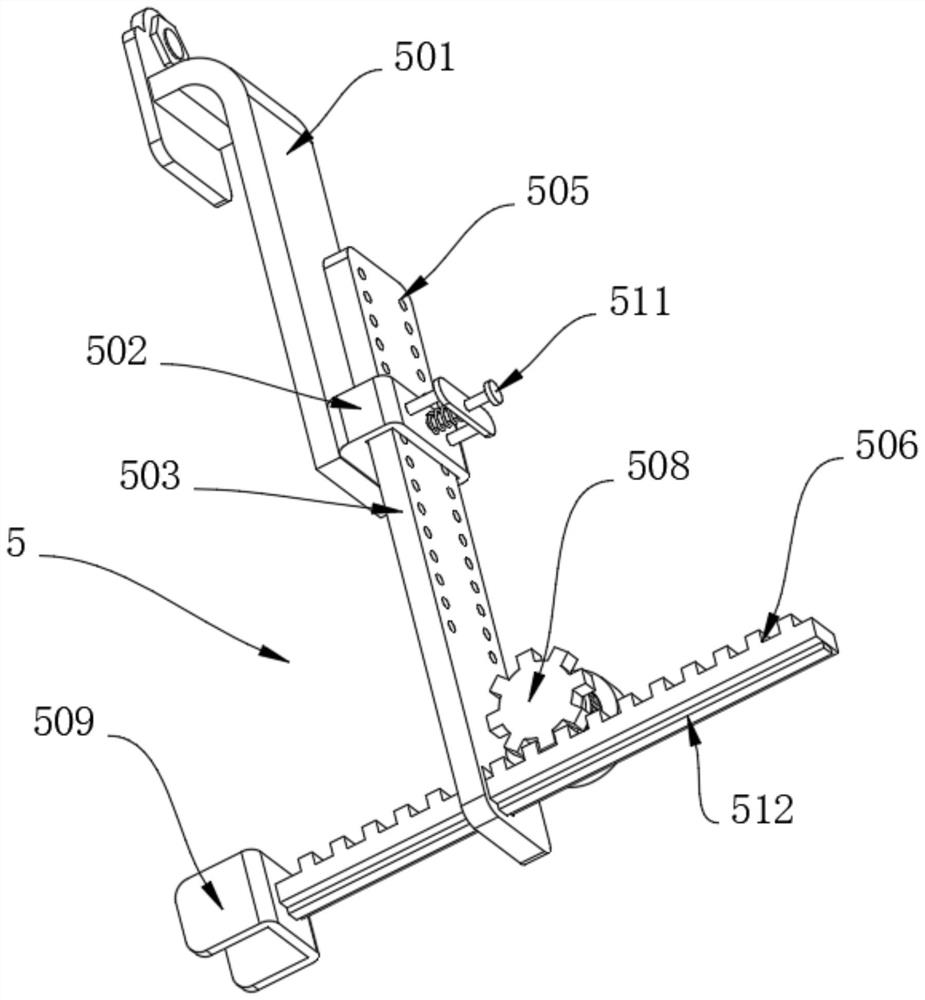

[0032] like image 3 andFigure 4 , The retaining structure 5 comprises a holder 501, the holder 501 is secured to the surface by means of a bolt of the hanger 1, the solid surface mount ring 502 with stop 501, the stop ring 502 is slidabl...

Embodiment 2

[0038] Example 2, on the basis of Example 1, the surface of the holder 3 is provided with cleaning structure 7, the structure 7 comprises a turntable 71 clean, turntable 71 is rotatably connected to the surface, the surface of the turntable 71 the holder 3 with solid scraping rods 72, 72 remote from the rod-end 71 of the turntable as a tip, the surface of the turntable 71 is inserted a threaded screw 73 is provided with the holder 3 corresponds to the position of the screw 73 with a solid rubber pad 74, may reach the clamper 3 claw stained with dirt simple cleaning effect, and does not require clean-up may be temporary housing fixed scraping effect on the lever 72, the side away from the drive wheel 71 fixedly arranged on the handle 2 of 75, 75 of the handle cross-section as a "Z" shape, that can be reached rapidly rotating disk 71, rotating disk 71 driven by the rod-effect of the mobile 72, and after a long time use of the holder 3, the holder 3 due to the hook clamp stop hook sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com