Laminated concrete member and joint structure and construction method thereof

A technology of concrete and components, applied in building components, building structures, floor slabs, etc., can solve troublesome and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 2-8 The application is described in further detail.

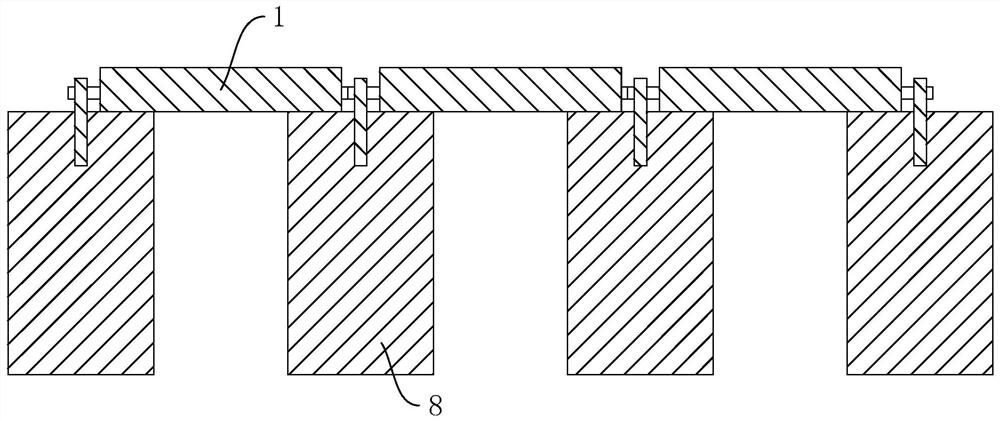

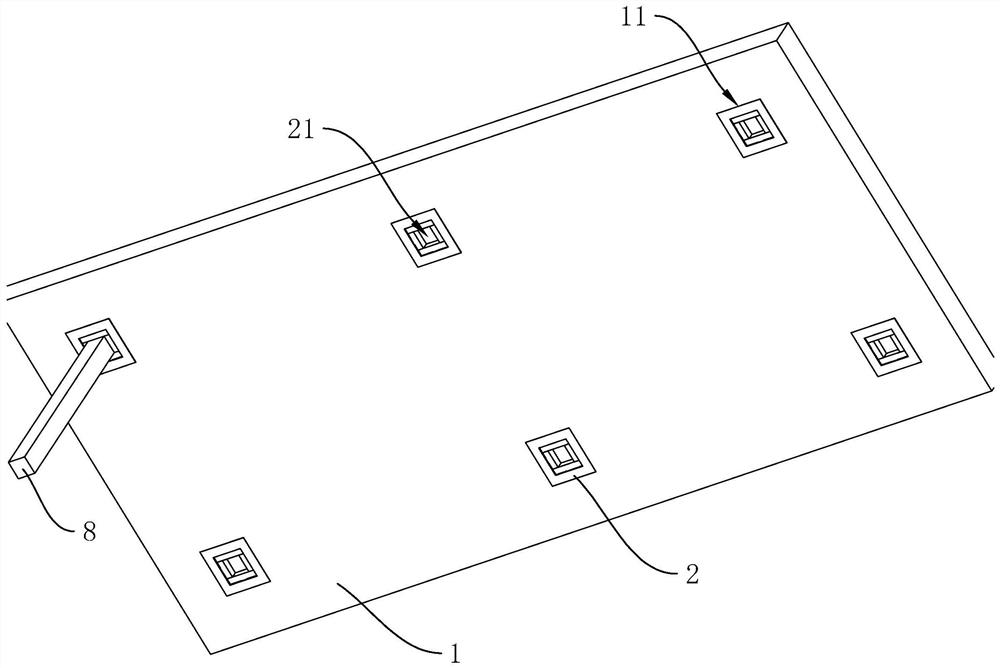

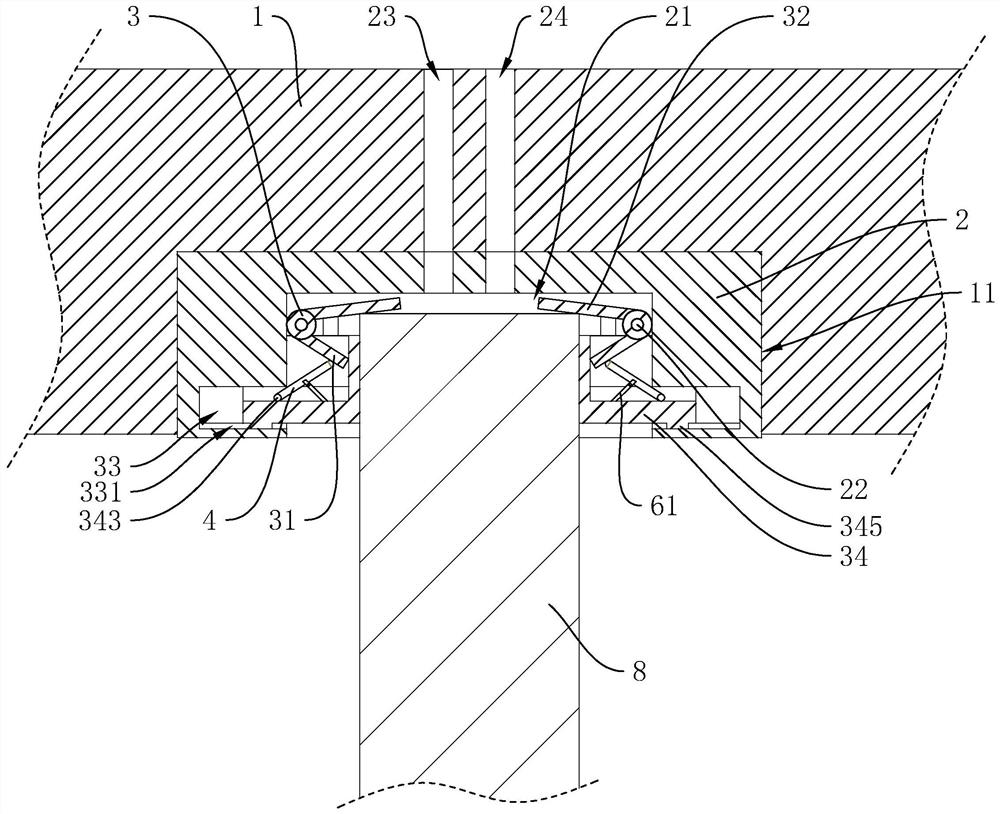

[0045] The embodiment of the present application discloses a composite concrete component. see figure 2 , The superimposed concrete member includes a floor 1, and the bottom of the floor 1 is provided with a plurality of accommodation grooves 11 with openings in a square structure. The floor 1 is provided with an accommodating block 2 , and the accommodating block 2 is clamped and fixed in the accommodating groove 11 . The containing block 2 and the floor 1 can be produced separately. After the production is completed, the containing block 2 is clamped and fixed in the containing groove 11 after smearing cement on the side walls of the containing block 2.

[0046] see image 3 , The middle position of the bottom of the receiving block 2 is provided with an insertion groove 21, the diameter of the insertion groove 21 is larger than the diameter of the column 8, and the column 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com