A new type of uncoupled backfill support method for steel frames in roadways with complex broken surrounding rocks

A technology for crushing surrounding rocks and roadways, which is applied in the field of new uncoupled steel frame backfill support for complex broken surrounding rock roadways, which can solve the problems of increasing the secondary maintenance of roadways in the service cycle of the roadway, so as to reduce cleaning work, reduce workload, The effect of slowing down the deformation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

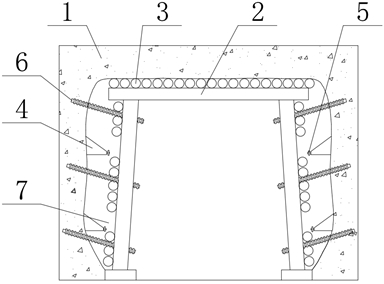

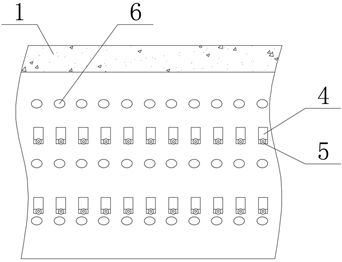

[0042] see Figure 1-2 , the present invention provides a kind of technical scheme:

[0043]A new type of steel frame uncoupled backfill support method for complex broken surrounding rock roadway, including erecting trapezoidal steel support modules for supporting the roadway, the support method also includes a non-coupling backfill process module, a non-coupling backfill process module It is used to increase the initial service cycle of the roadway. The uncoupled backfill process module includes the roadway over-excavation process module before the trapezoidal steel support 2 supports are raised, and the log backfill process module after the trapezoidal steel support 2 support is raised. The excavation process module also includes a reinforced vertical plate process module, and the log backfill process module also includes a pre-dimensional window process module;

[0044] The roadway over-excavation process module is used to actively release the pressure, which can reserve t...

Embodiment 2

[0052] see Figure 1-2 , the present invention provides a kind of technical scheme:

[0053] A new type of steel frame uncoupled backfill support method for complex broken surrounding rock roadway, including erecting trapezoidal steel support modules for supporting the roadway, the support method also includes a non-coupling backfill process module, a non-coupling backfill process module It is used to increase the initial service period of the roadway. The uncoupled backfill process module includes the roadway over-excavation process module before the trapezoidal steel support 2 supports are raised, the log backfill process module after the trapezoidal steel support 2 support is raised, and the log The backfilling process module also includes a pre-dimensional window process module;

[0054] The log backfilling process module is used to increase the support force area of the trapezoidal steel bracket 2 and prevent the scum from falling off the roadway. Backfilling of suppo...

Embodiment 3

[0061] see Figure 1-2 , the present invention provides a kind of technical scheme:

[0062] A new type of steel frame uncoupled backfill support method for complex broken surrounding rock roadway, including erecting trapezoidal steel support modules for supporting the roadway, the support method also includes a non-coupling backfill process module, a non-coupling backfill process module It is used to increase the initial service cycle of the roadway. The uncoupled backfill process module includes the roadway over-excavation process module before the trapezoidal steel support 2 supports are raised, and the log backfill process module after the trapezoidal steel support 2 support is raised. The excavation process module also includes a reinforced vertical plate process module, and the log backfill process module also includes a pre-dimensional window process module;

[0063] The roadway over-excavation process module is used to actively release the pressure, which can reserve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com