Full-circle needle beam lining trolley and construction method thereof

A technology of lining trolleys and round needles, which is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc., can solve the problems that the strength of the concrete structure at the bottom is not up to standard, the material distribution mechanism cannot be flexibly adjusted, and the process of opening and closing work windows is cumbersome, etc. The effect of high compaction strength, low labor intensity and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

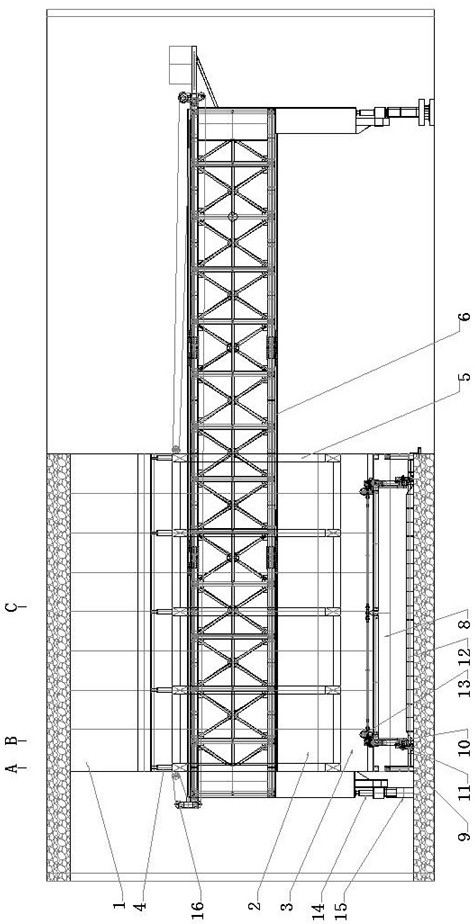

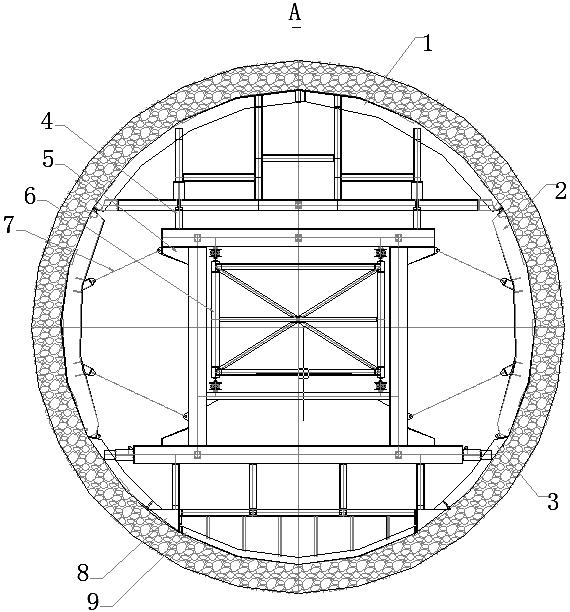

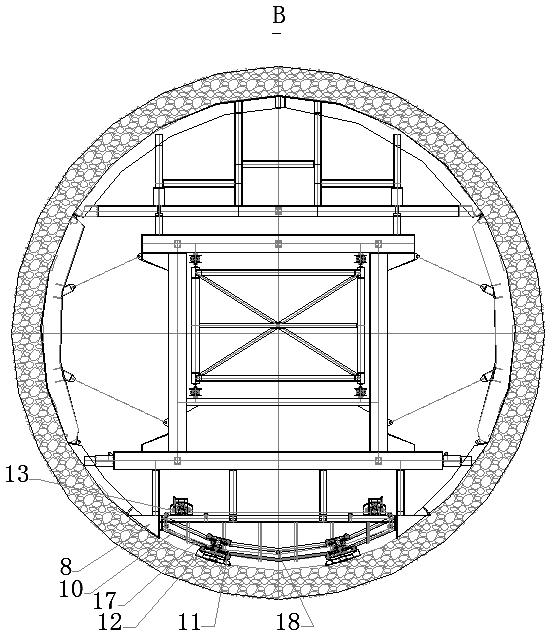

[0042]A full-circle needle beam lining trolley, comprising a top mold 1, a side mold 2, a side mold 3, a top mold oil cylinder 4, a needle beam frame 5, a needle beam 6, a support jack 7, a side beam 8, a longitudinal guide rail 9, a ring Guide rail 10, circular rail trolley 11, sliding template 12, circular rail trolley drive mechanism 13, needle beam oil cylinder 14, needle beam base 15 and needle beam traction mechanism 16. The upper plane of the side beam 8 is rigidly connected with the side mold 3 and the needle beam frame 5, the inner plane is respectively rigidly connected with the longitudinal guide rail 9, the ring guide rail 10, and the needle beam frame 5, and the ring guide rail 10 is slidably connected with the ring rail trolley 11. The rail trolley 11 is rigidly connected to the sliding formwork 12; the ring rail trolley drive mechanism 13 is rigidly connected to the needle beam frame 5, the loop rail trolley drive mechanism 13 is linked with the traction chain 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com