Digital twinning system oriented to discrete workshop production process and construction method thereof

A production process and construction method technology, applied in the general control system, control/regulation system, program control, etc., can solve the problem of multi-source heterogeneity of information and data in discrete manufacturing workshops, insufficient fusion of information and physics, low degree of real-time dynamic data visualization, etc. problem, to achieve the effect of remote monitoring and real-time mapping, which is conducive to the development of intelligence and real-time visual display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

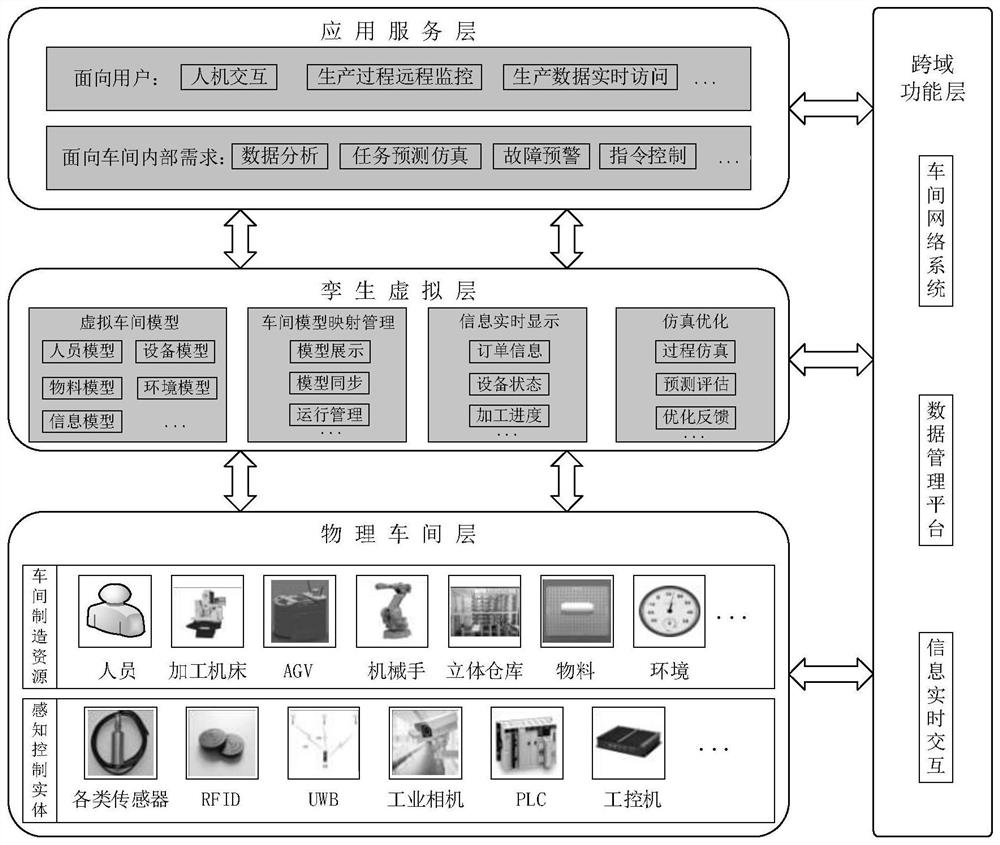

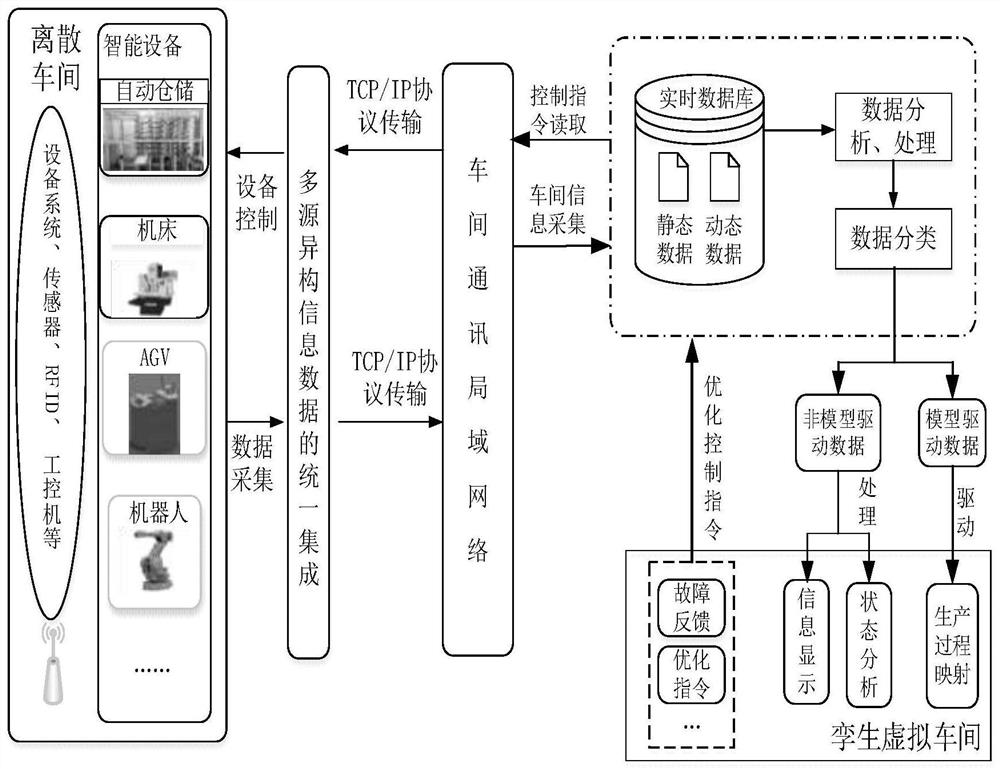

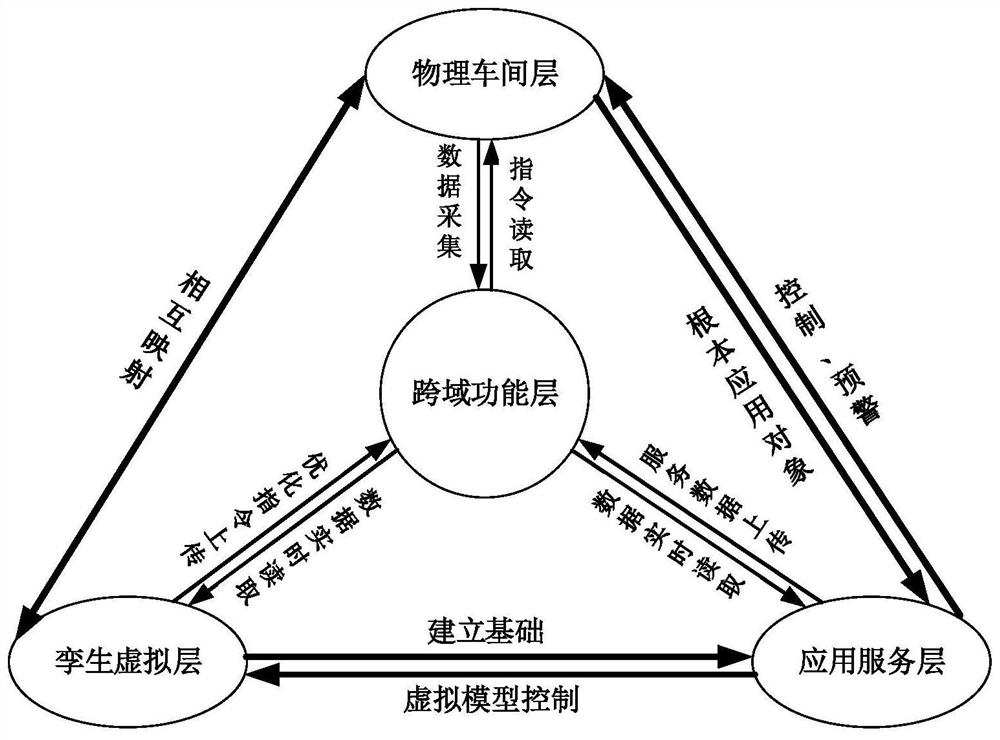

[0047] This embodiment provides a digital twin system oriented to the production process of a discrete workshop, the digital twin system includes a physical workshop layer, a twin virtual layer, an application service layer, and a cross-domain functional layer; wherein, the physical workshop layer includes production resources and perceived control entities;

[0048] The twin virtual layer provides digital models for production resources and perception control entities in discrete workshops, and performs real-time data collection on them;

[0049] The cross-domain functional layer integrates various information data results of the physical workshop layer and the twin virtual layer, and provides corresponding functional services according to the actual production process requirements.

[0050] Further, the physical workshop layer is a discrete processing workshop entity, and the discrete workshop production resources refer to the personnel, equipment, materials, environment and...

Embodiment 2

[0092] The present application also provides a construction method for the above-mentioned digital twin system oriented to the discrete workshop production process, the construction method comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com