Steel plate production informatization process tracing system and method based on RFID technology

A traceability system and RFID tag technology, applied in the field of steel plate production information process traceability system based on RFID technology, can solve various extreme environments such as unsatisfactory luggage identification success rate, easy wrinkle and damage of luggage barcode labels, and auxiliary sorting efficiency It can improve the efficiency and accuracy of reading, collect and check accurate information, and optimize the steel plate production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

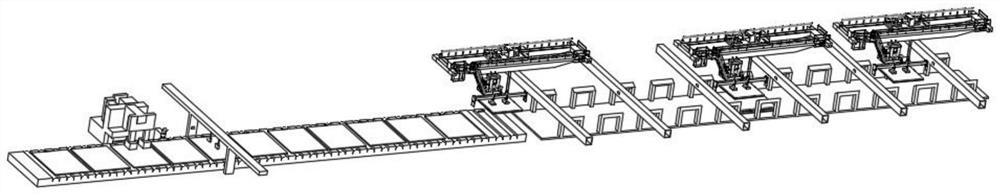

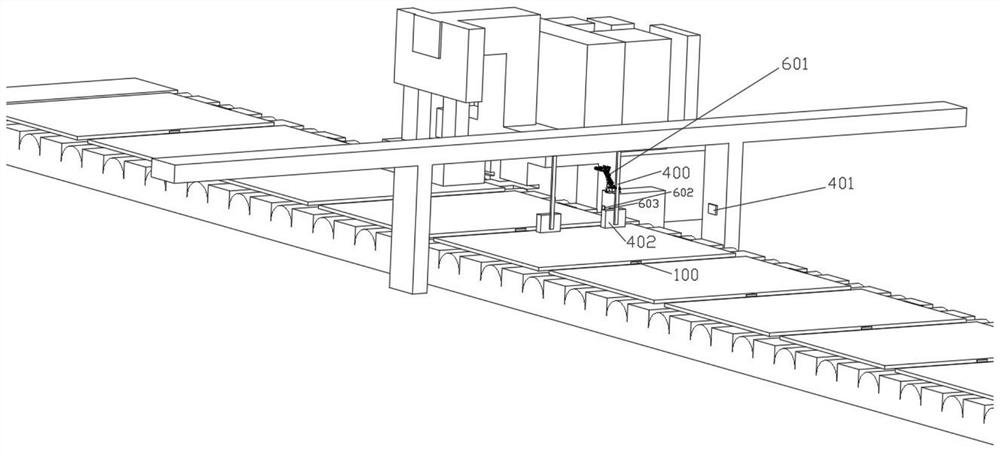

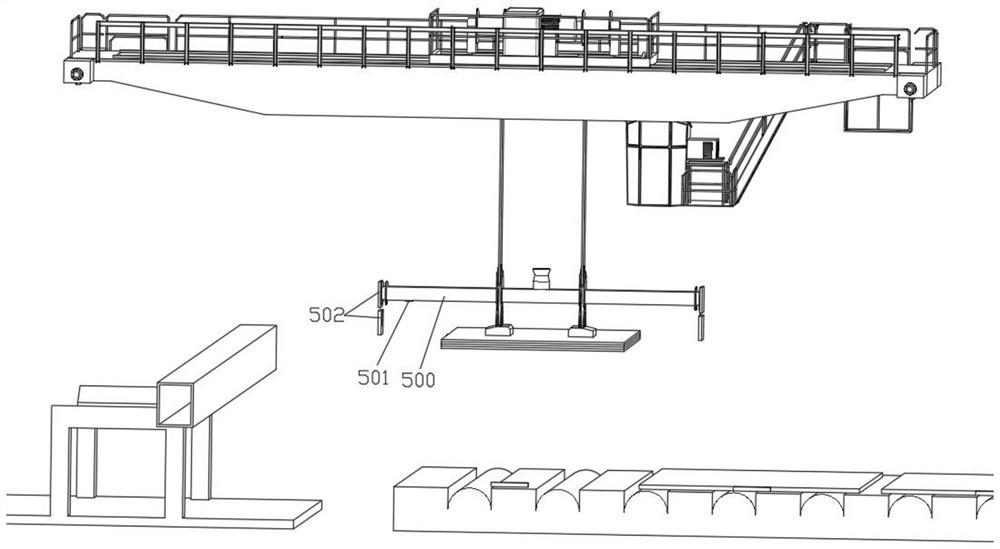

[0052] Steel plate RFID tags 100, storage location RFID tags 200, RFID tag initialization equipment 300, transmission belt RFID collection equipment 400, transmission belt RFID reader 401, transmission belt RFID antenna 402, driving RFID collection equipment 500, driving RFID reader 501 , Driving RFID antenna 502, automatic labeling equipment 600, manipulator 601, position detection sensor 602, real-time alarm 603.

[0053] The traceability process of the steel plate production informatization process based on RFID technology described in this method is as follows: use the RFID card issuing machine 300 to initialize the RFID tag 100, that is, to associate the steel plate production information with the RFID tag 100 information in the intelligent production management system, and the steel plate production information Including but not limited to steel plate material, thickness, external dimensions, surface features and other information; see figure 2 As shown, when the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com