An intelligent environment-friendly asphalt mixing equipment loading system and its use method

An asphalt mixing and loading system technology, used in roads, buildings, road repair and other directions, can solve the problems of low automation, noise pollution, low safety, etc., and achieve the effect of clear outline and noise pollution isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

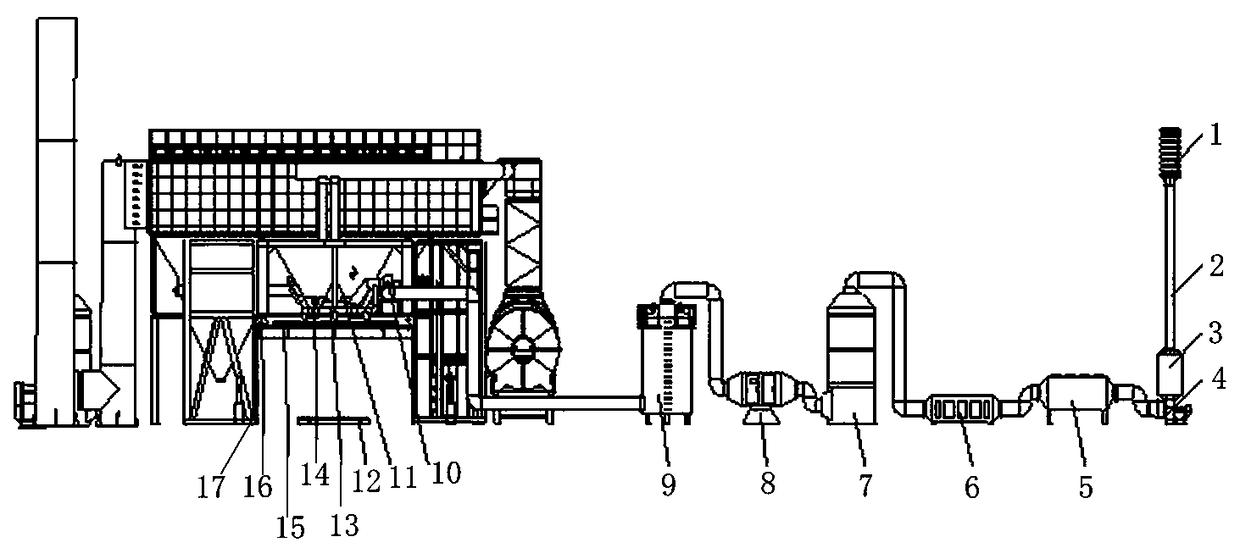

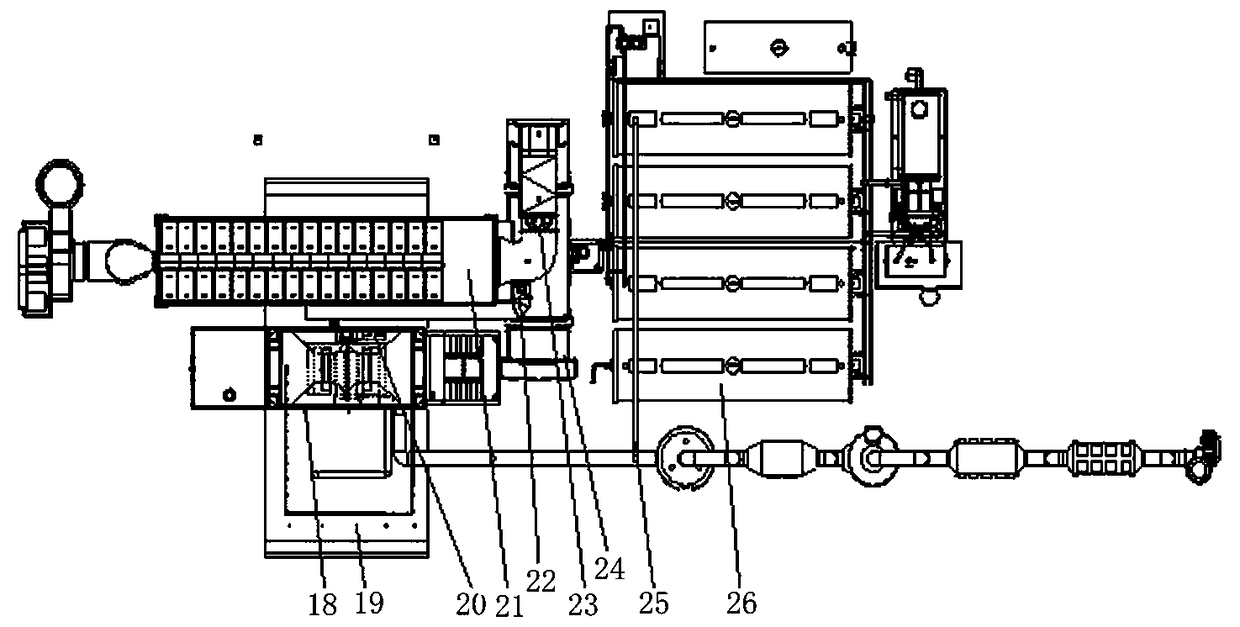

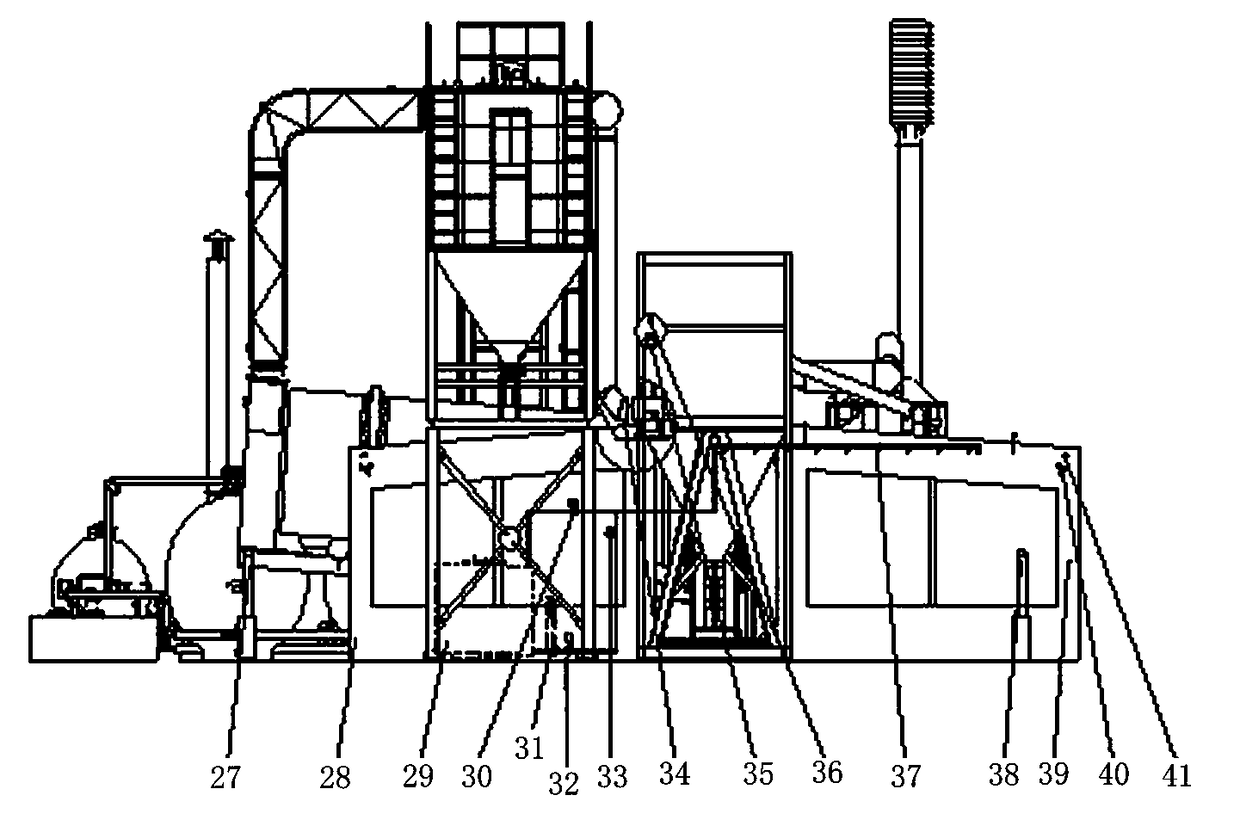

[0041] See attached Figure 1-8 As shown in the figure, an intelligent and environment-friendly asphalt mixing equipment loading system includes an adaptive closing module of the lane door, an intelligent loading module for finished materials, an asphalt flue gas treatment module, a dust treatment module, a dry fog dust suppression module and a control system, and an adaptive closing module for the lane door. The working mechanism of the closing module is: when the loading vehicle is ready for loading operation, before the vehicle enters the loading area of the mixing building, the first infrared sensing device (27) is triggered, and the first infrared sensing device (27) senses the signal of the vehicle entering the site And transmit the signal to the control system, the control system perceives the signal and transmits the processed signal to the first rolling door driving mechanism, and the first rolling door driving mechanism opens the first rolling door (28); when the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com