Environmental protection atmospheric emission standard gas furnace with natural smokke collection for comusible house refuse

A domestic garbage and standard gas technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of large equipment, complex structure, and failure to capture flue gas, and achieve the effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

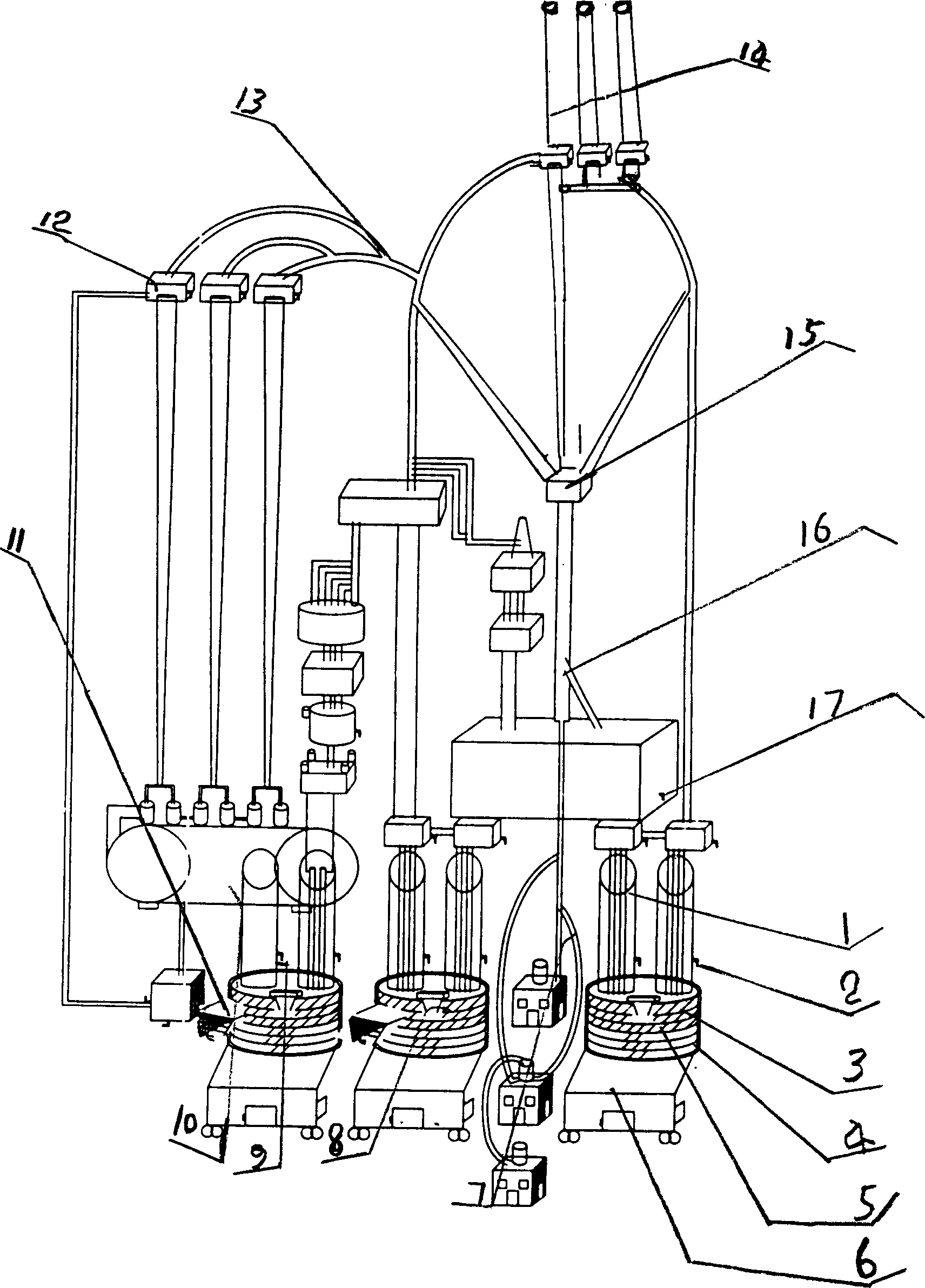

[0011] The present invention combustible living garbage naturally captures flue gas environmental protection and new atmospheric standard gas furnace, which consists of a one-piece furnace 1, a steam exhaust valve 2, a furnace 3, a heat preservation water jacket 4, a vertical pipe furnace grate 5, and a carbon slag storage device 6 , Pollution discharge control valve 7, garbage closed drying and lowering channel 8, water injector 9, flue gas convector 10, garbage closed feeding box 11, flue gas deflector 12, flue gas purifier 13, one-piece chimney 14 , smoke exhauster 15, air guide pipe 16, steam oven 17 forms.

[0012] In the furnace 3 of the present invention, a riser grate 5 is arranged, and the grate spacing of the riser grate 5 is gradually spaced from top to bottom, and a garbage closed drying discharge channel 8 is installed above the top riser grate 5, which is continuously The top of the body furnace 1 is equipped with a flue gas convector 10, and the two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com