Reflow soldering method and tool for CCGA-microwave device mixed printed board assembly

A microwave device, reflow soldering technology, applied in the direction of assembling printed circuits with electrical components, printed circuit manufacturing, electrical components, etc., to achieve the effects of stable and reliable device assembly quality, simple operation, and high-reliability assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

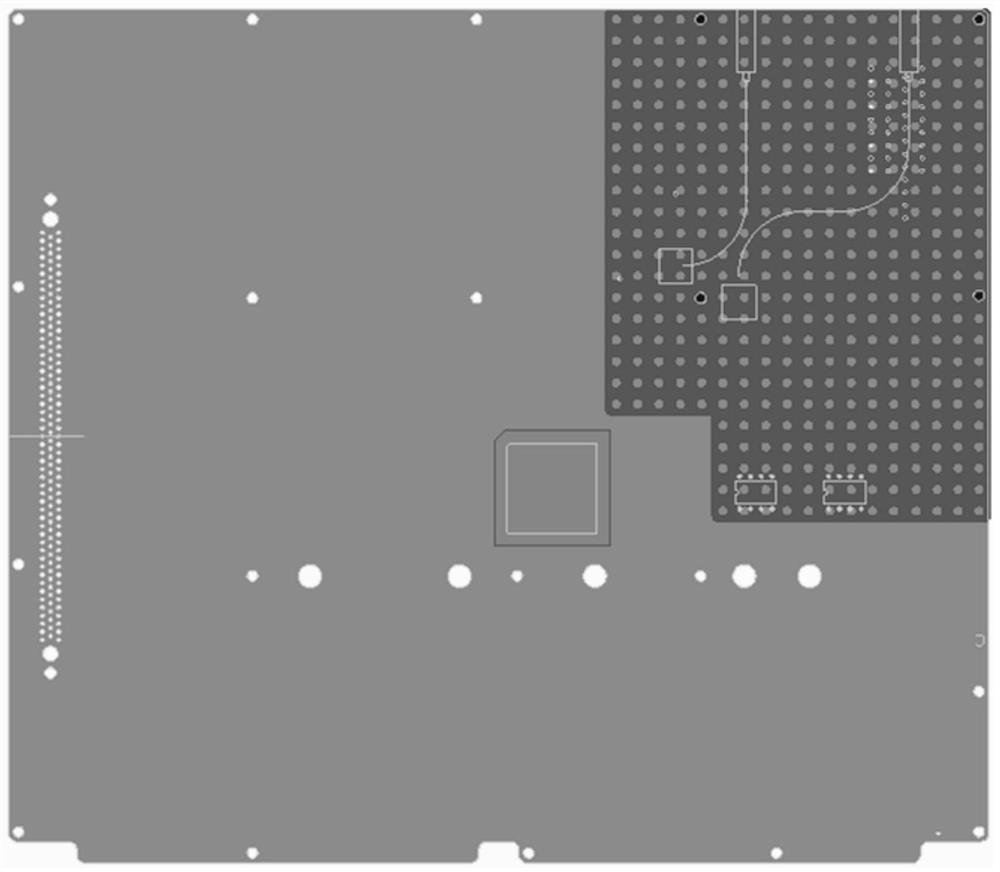

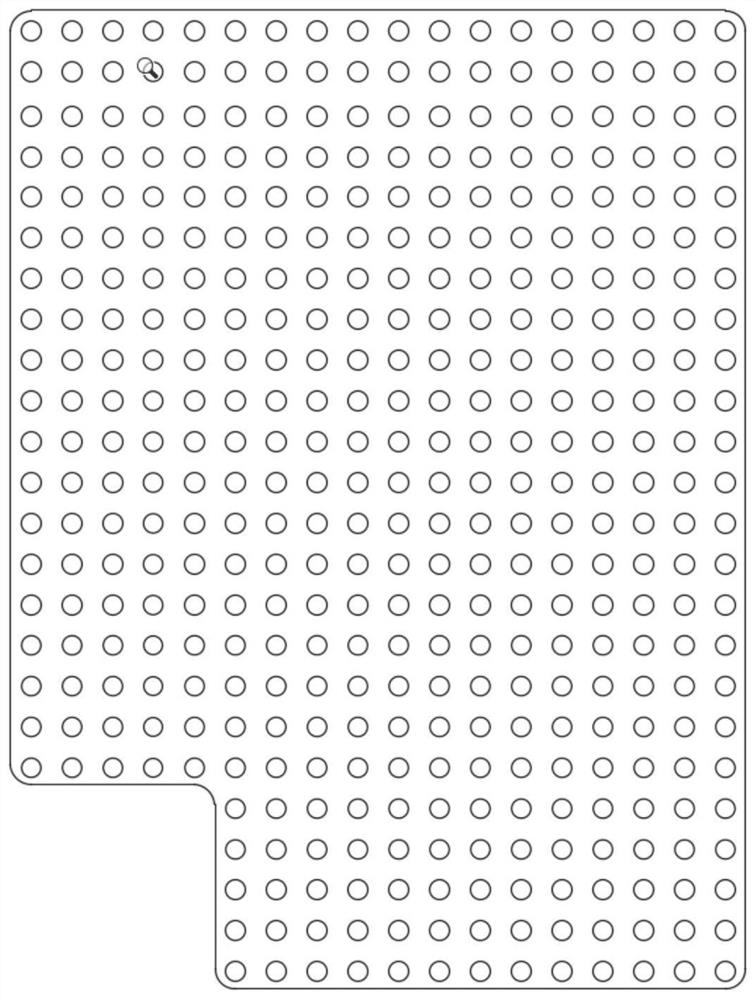

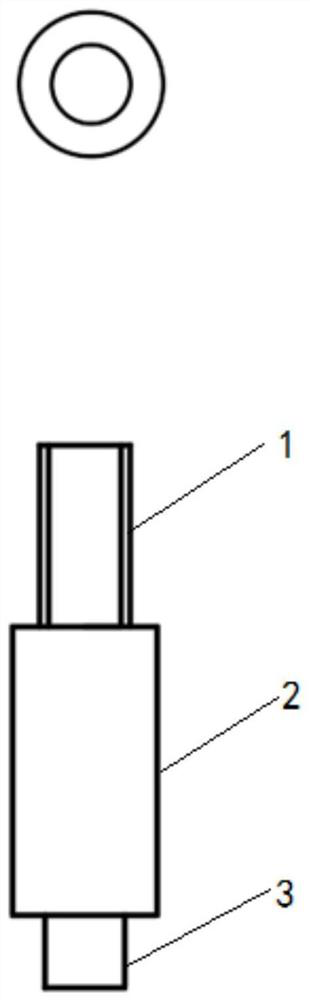

[0036] Such as figure 1 As shown, the main technical solution of this embodiment is to use the heat insulation screen to block the thermal effect, reduce the air volume reaching the surface of the device in the hot air reflow oven, and increase the heat capacity of the microwave device welding area through the heat shield of the tooling, so that the microwave area of the printed board is in line with the The temperature difference is formed in other areas to achieve the integrated assembly of integrated microwave circuits and dedicated digital circuits of the same component, and solve the problem of incompatibility of soldering temperature between CCGA and microwave devices.

[0037] The printed board assembly selected in this embodiment requires a total of one CCGA packaged device and five microwave dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com