Multi-column liquid filling and cleaning mechanism

A cleaning mechanism and filling technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems affecting filling efficiency, high precision requirements of parts, remaining stubborn stains, etc. The effect of fully automatic cleaning work, low requirements on parts accuracy, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

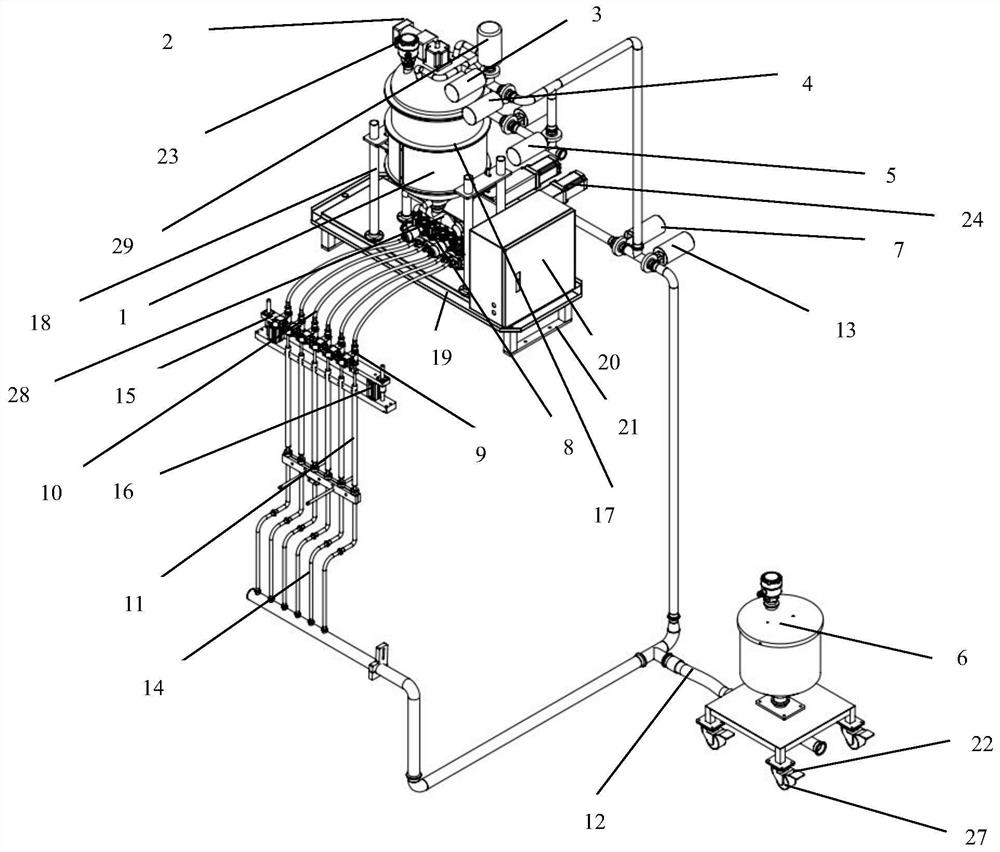

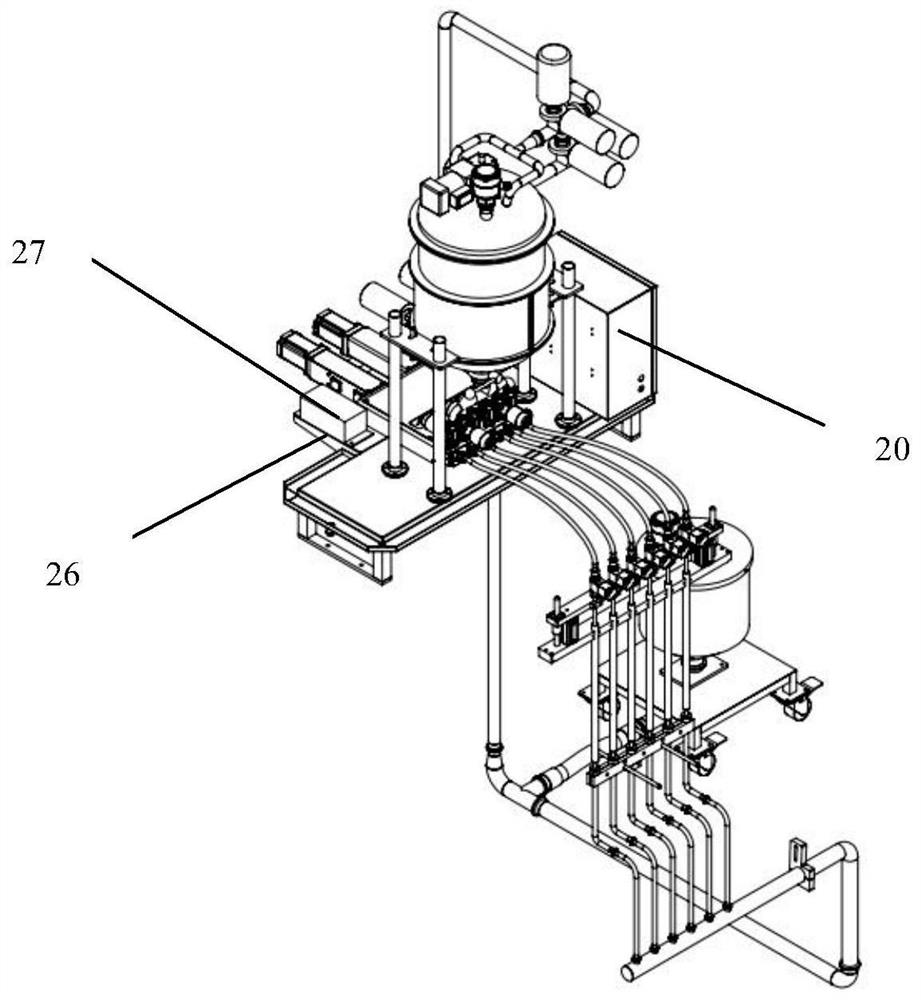

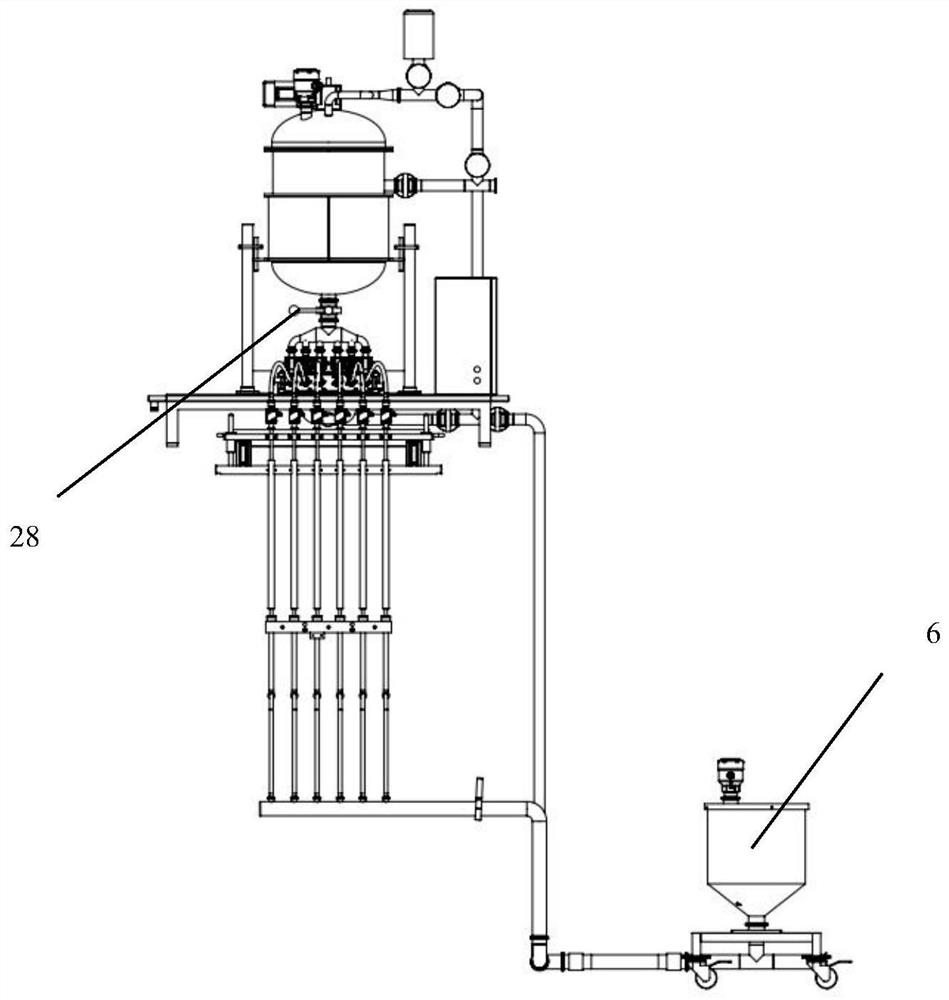

[0032] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

[0033] Such as Figure 1-3 As shown, a multi-row liquid filling and cleaning mechanism includes a 50L material barrel 1, a stirring mechanism and a spraying mechanism, the stirring mechanism includes a stirring motor 2, the spraying mechanism includes a spray ball 23, and the 50L material tank Stirring motor 2 on the top of barrel 1, the stirring motor drives the stirring blades to rotate, there are two rotating spray heads inside the 50L material barrel 1, and the flow is diverted through the tee, and one end of the first pneumatic butterfly valve 3 is connected to the breathing valve 29 , the other end is connected to a tee, the tee is connected to the second pneumatic butterfly valve 4, the second pneumatic butterfly valve 4 is connected to the elbow, one end of the tee is connected to one end of the third pneumatic butterfly valve 5, and the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com