Punching forming die

A molding die and workbench technology, which is applied in the field of auto parts processing, can solve problems such as incomplete punching, low work efficiency, and cutting deviation, and achieve the effects of reducing energy consumption losses, improving work efficiency, and improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

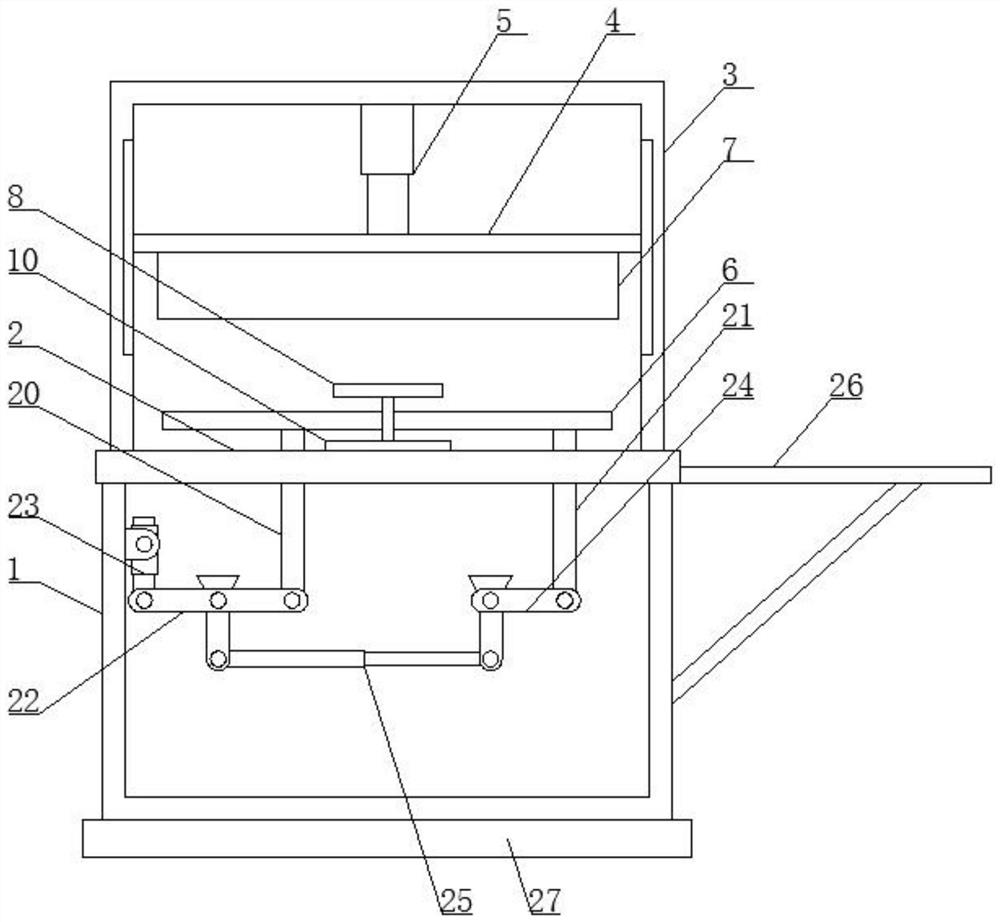

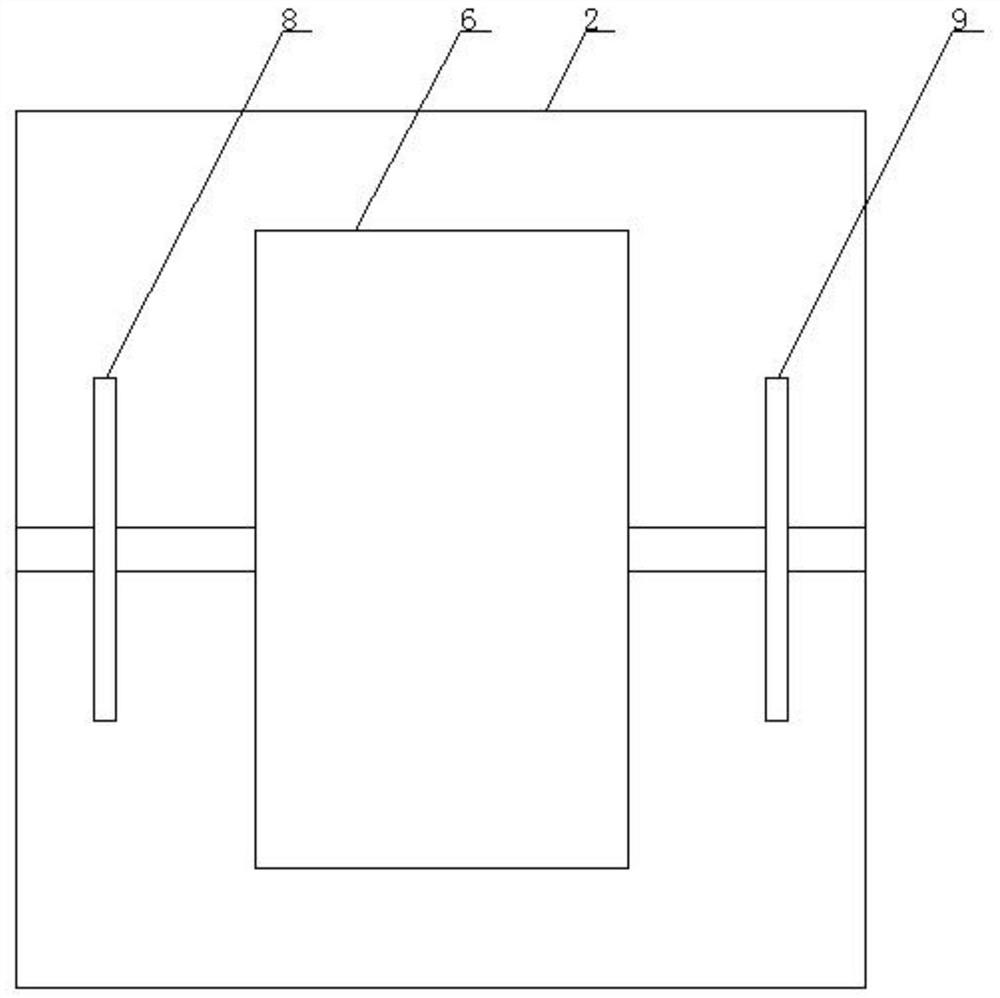

Embodiment 1

[0025] Such as Figure 1-3 As shown, the punching molding die according to the embodiment of the present invention includes a base 1 and a workbench 2 located at the top of the base 1, the top of the workbench 2 is provided with a housing 3, and the housing 3 It is a cavity structure with side openings, and the housing 3 is provided with a horizontally arranged moving plate 4, and the top end of the moving plate 4 is provided with a telescopic cylinder 5 connected to the housing 3, and the working The top of the platform 2 is provided with a horizontally arranged loading plate 6, the loading plate 6 is connected with the workbench 2 through an adjustment assembly, and the bottom end of the moving plate 4 is provided with a punching block 7, so that The top of the workbench 2 and the both sides of the loading plate 6 are provided with a symmetrically arranged limiting plate one 8 and a limiting plate two 9, and the limiting plate one 8 and the limiting plate two 9 pass through ...

Embodiment 2

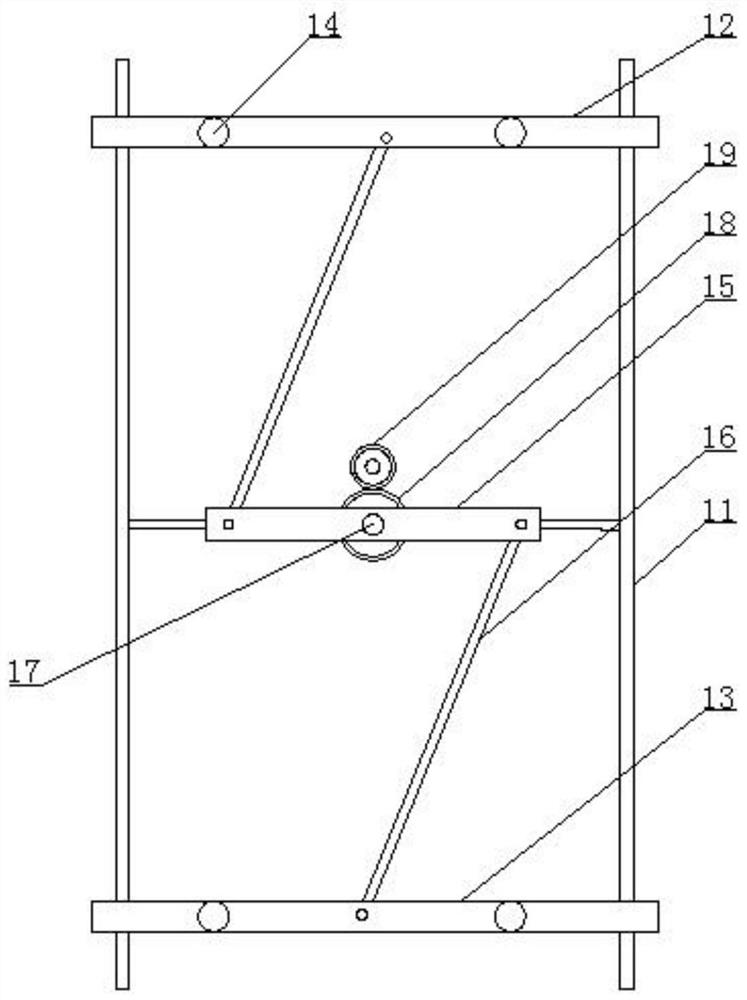

[0028] Such as Figure 1-3 As shown, the movable rod 15 is connected with the horizontal plate 10 through the rotating shaft 17, the rotating shaft 17 is provided with a gear one 18, and one side of the gear one 18 is provided with a transmission gear 19 matched therewith, The shaft center of the transmission gear 19 is connected with the output end of the drive motor located in the horizontal plate 10, and the connecting rod 16 is respectively connected with the movable rod 15, the first slider 12 and the slider through a rotating shaft. Two 13 are connected, and the movable rod 15 is connected with the guide rod 11 through a connecting column.

Embodiment 3

[0030] Such as Figure 1-3 As shown, the adjustment assembly includes a column 1 20 and a column 2 21 symmetrically arranged in the base 1, and the top ends of the column 1 20 and the column 2 21 extend to the top of the workbench 2 and the The loading plate 6 is connected, the bottom end of the column one 20 is provided with a T-shaped bar 22, and the T-shaped bar 22 is connected with the base 1 through a fixed shaft one, and the T-shaped bar 22 One side is provided with the electric telescopic rod 23 that is connected with described base 1, and described T-bar 22 is connected with described electric telescopic rod 23 and described column one 20 respectively by movable shaft one, and described column two 21 The bottom end of the L-shaped rod 24 is provided, and the L-shaped rod 24 is connected with the base 1 through the fixed shaft two, and the bottom end of the L-shaped rod 24 is provided with a A hydraulic telescopic rod 25, the hydraulic telescopic rod 25 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com