Automatic metal material polishing device

An automatic technology for metal materials, applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of inability to grind, poor grinding effect, etc., and achieve the effect of maintaining stability, improving grinding effect, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

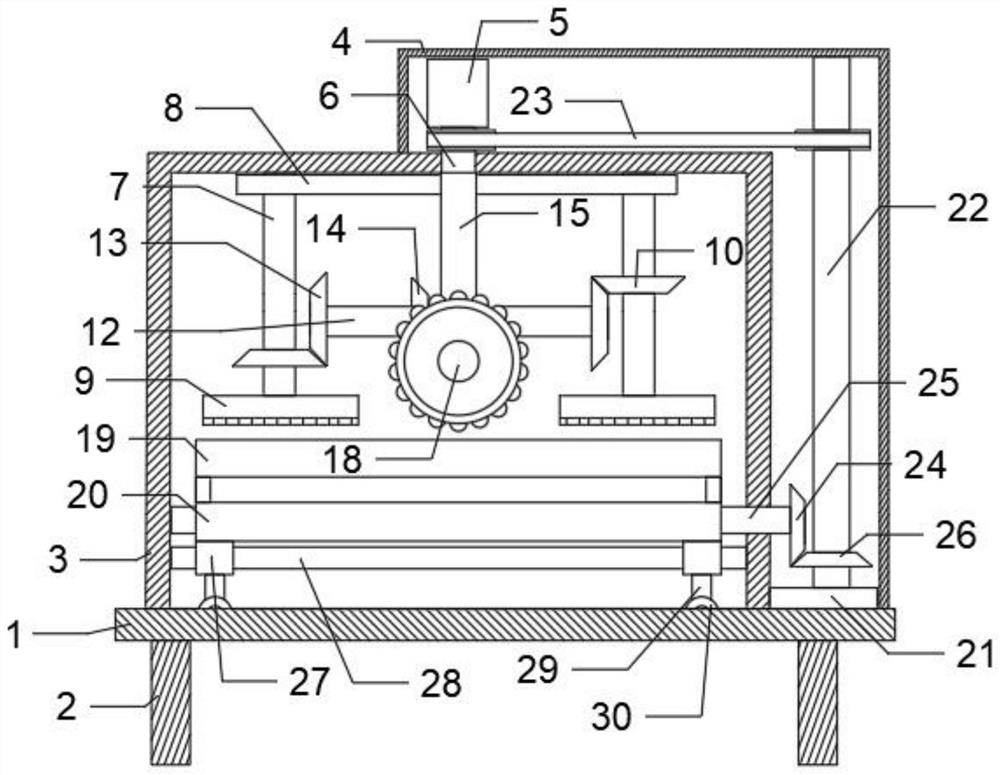

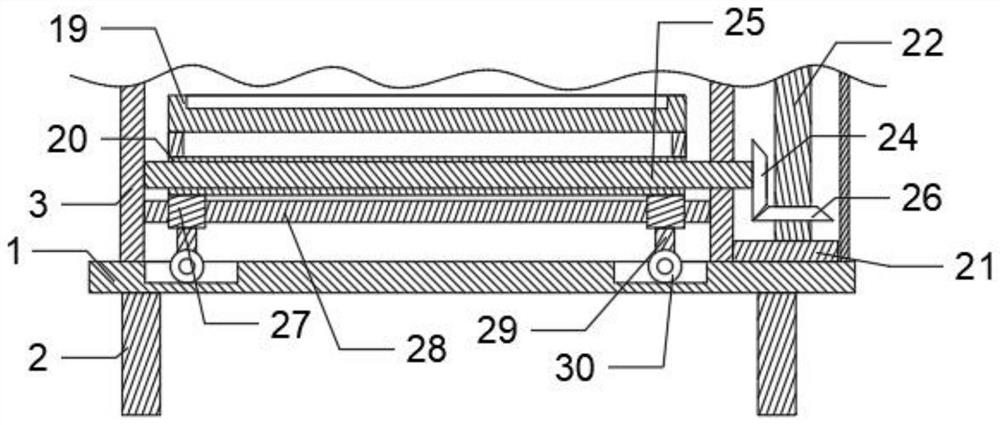

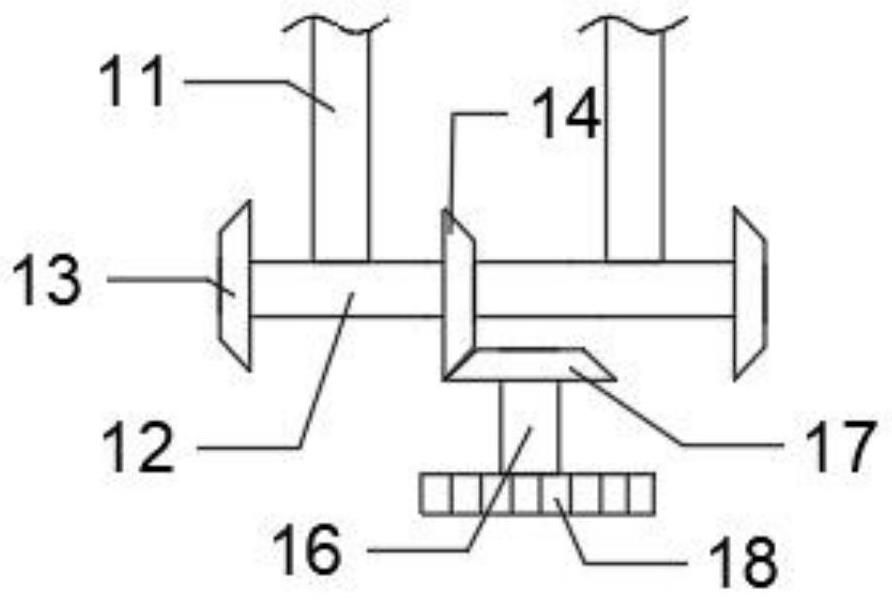

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0026] Such as Figure 1 to Figure 3 As shown, an automatic grinding device for metal materials includes a base 1, two support columns 2 are fixedly connected to the lower end of the base 1, a support platform 3 is installed on the upper end of the base 1, a protective frame 4 is arranged on the outer side of the support platform 3, and the lower end of the protective frame 4 It is fixedly connected with the upper end of the base 1, and the protective frame 4 is provided with a motor 5 which is bolted to the top of the support platform 3. The output shaft of the motor 5 is connected to the drive shaft 6 which penetrates into the support platform 3. The outer side of the drive shaft 6 is connected to a second One transmission gear, the top wall of the support platform 3 is rotatably connected with two active rods 7, and the two active rods 7 are respectiv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap