Turnover device for correcting positions of products on warehouse storage line

A technology of overturning device and storage line, which is applied in the direction of transportation and packaging, conveyor objects, roller tables, etc. It can solve the problems that the manipulator cannot pick up objects, affect work efficiency and economic benefits, and position deviation, etc., and achieve convenience And the effect of high efficiency, ensuring stability and high efficiency, and expanding the use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

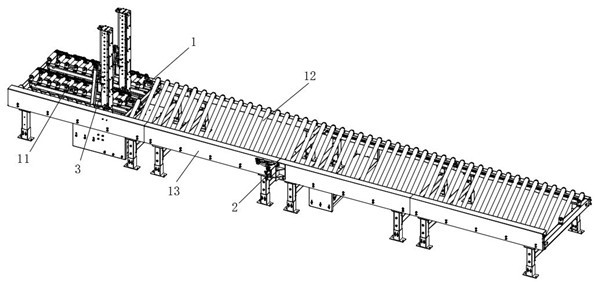

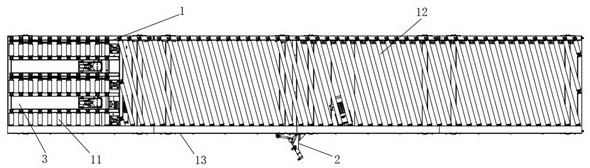

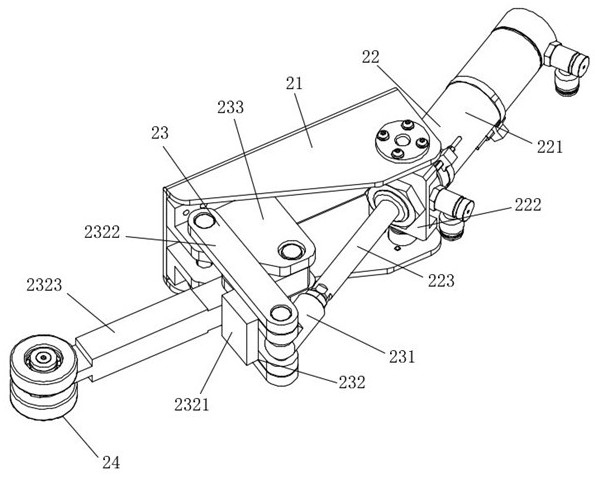

[0027] An overturning device for the upright position of products in a warehousing storage line, the overturning device mainly includes a roller device 1, a horizontal rotation mechanism 2 and a vertical overturning mechanism 3, wherein the roller device 1 includes a straight roller assembly 11, an inclined roller Components 12 and workbench 13, the workbench 13 is a working frame with a straight roller assembly 11 and an inclined roller assembly 12 installed on the surface, a horizontal rotation mechanism 2 and a vertical turning mechanism 3 installed on the side, and the inclined roller assembly 12 and the straight roller assembly 11 are adjacently spliced and installed on the workbench 13 to form a continuous roller circulation line for product transmission. The horizontal rotation mechanism 2 is installed at the inclined roller assembly 12, and the vertical turning mechanism 3 is installed at the straight roller assembly 11. In the warehouse storage line When transporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com