Formwork reinforcing structure of bare concrete wall post-cast strip and and construction method of formwork reinforcing structure

A technology of fair-faced concrete and formwork reinforcement, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, building construction, etc. Problems such as concrete expansion, gap flow, and unreasonable formwork reinforcement methods can save labor maintenance costs, reduce repair costs, and avoid dust pollution and noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

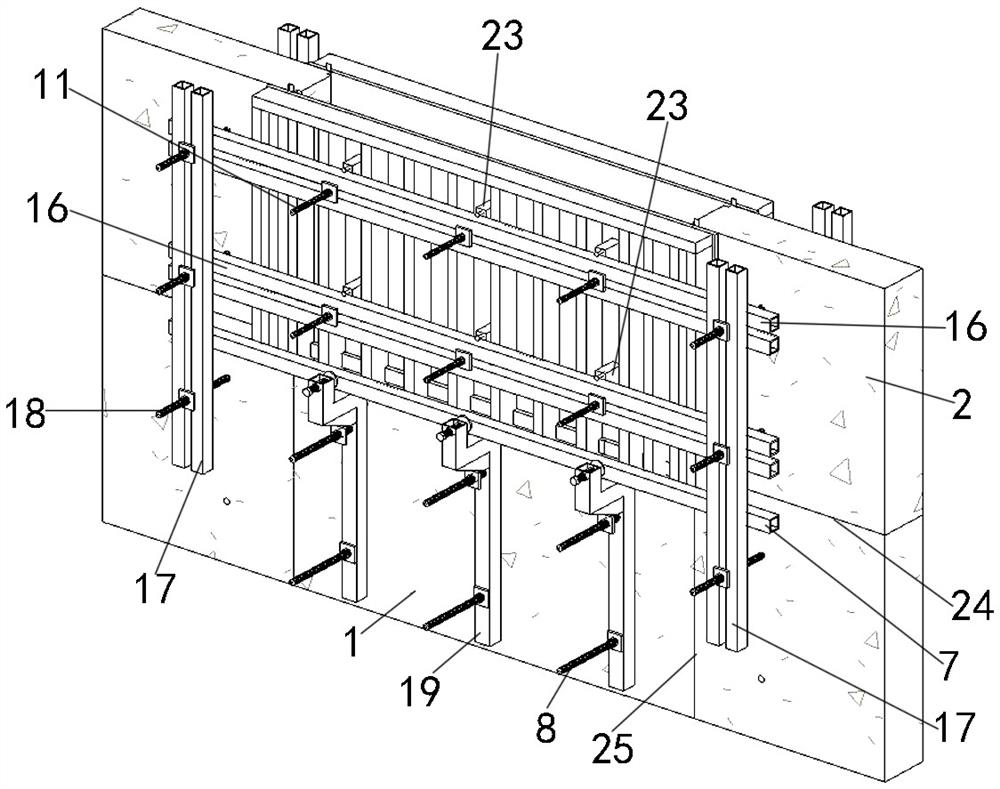

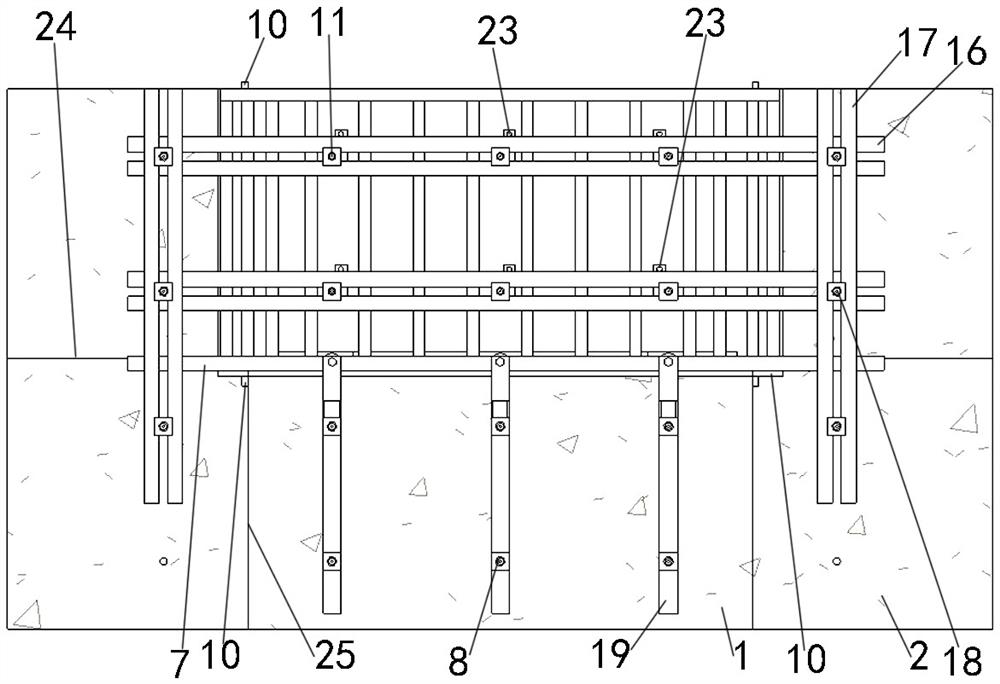

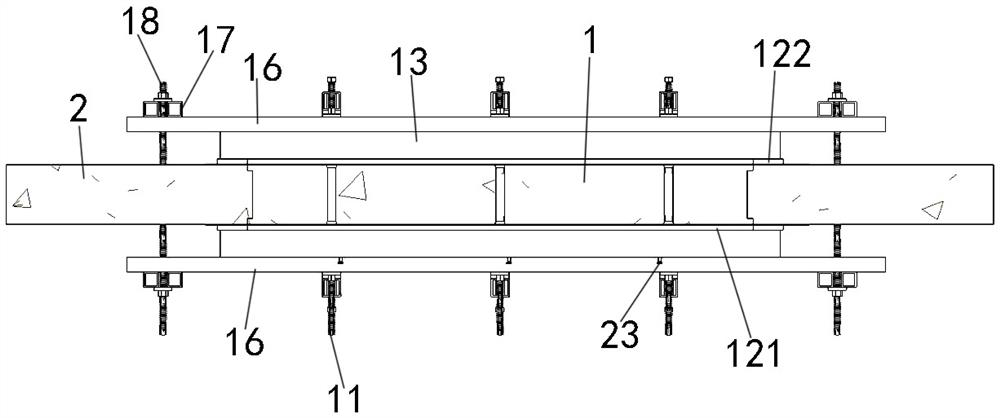

[0085] Examples see Figure 1-4 As shown, a formwork reinforcement structure of a post-casting belt of a fair-faced concrete wall includes a wall, and the wall includes a middle post-casting belt first-casting guide wall 1 and is integrally poured with the last-casting belt first-casting guide wall 1, located at For the side walls 2 on the left and right sides, the top elevation of the first pouring guide wall 1 is lower than the top elevation of the first pouring side wall 2, and the upper side of the first pouring guide wall 1, first A post-cast tape space 9 is formed between the poured side walls 2 .

[0086] see Figure 18 As shown, the end face of the pre-casting side wall 2 on the side of the post-casting tape space is a cohesion-enhancing surface, and the two edges of the cohesion-enhancing surface on the end face of the post-casting tape space have two concave corners The groove 20 is such that the cross-sectional shape of the end face is T-shaped, and a raised end f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap