Automatic test device and test method for multi-beam assembly

An automatic test device and automatic test technology are applied in the direction of measuring devices, measuring electricity, and measuring electrical variables. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the traditional multi-channel microwave component test, RF input and output modules are installed at both ends of the component under test. After the input and output modules, a switch matrix must be relied on to realize one-button automatic testing. This test method needs to use RF cables to transfer each channel of the RF input and output module to the switch matrix, and then connect the switch matrix to instruments such as Yanet. The entire system is bulky, and for components that require phase consistency, it is difficult to calibrate the phase between multiple RF transfer cables. In addition, the switch matrix is expensive, and such a system is difficult to popularize in actual use.

[0035] In order to solve the above technical problems, the following various embodiments of the multi-channel microwave component testing device are proposed.

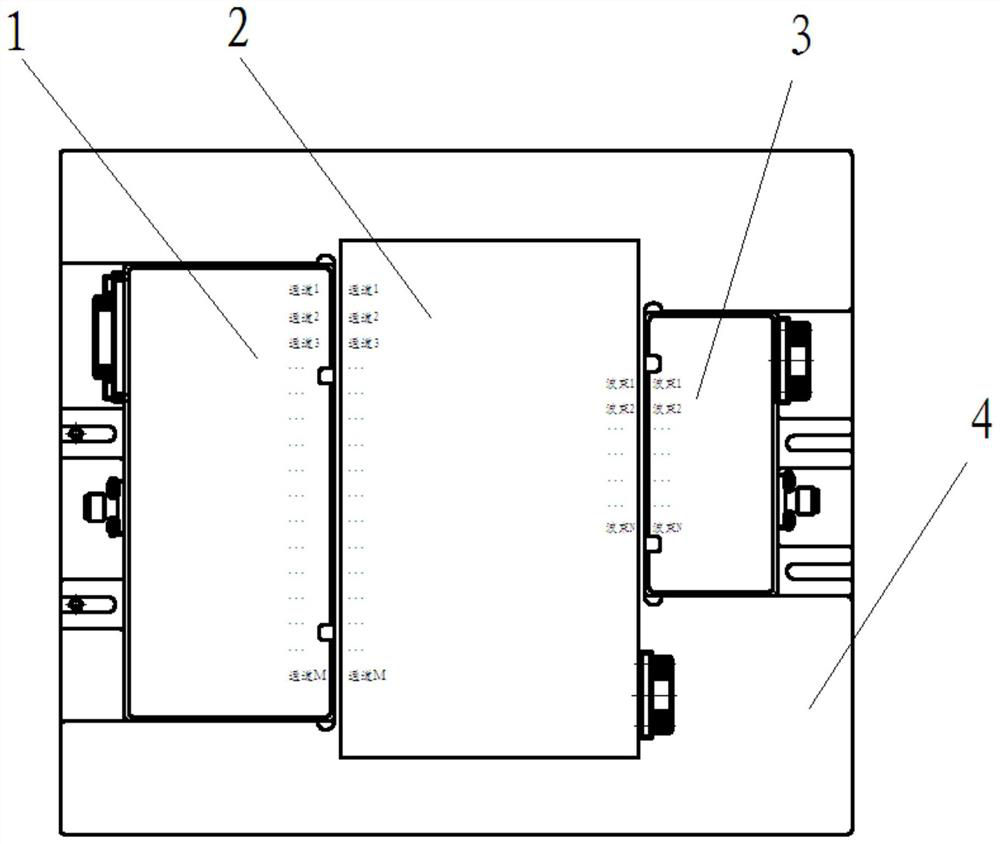

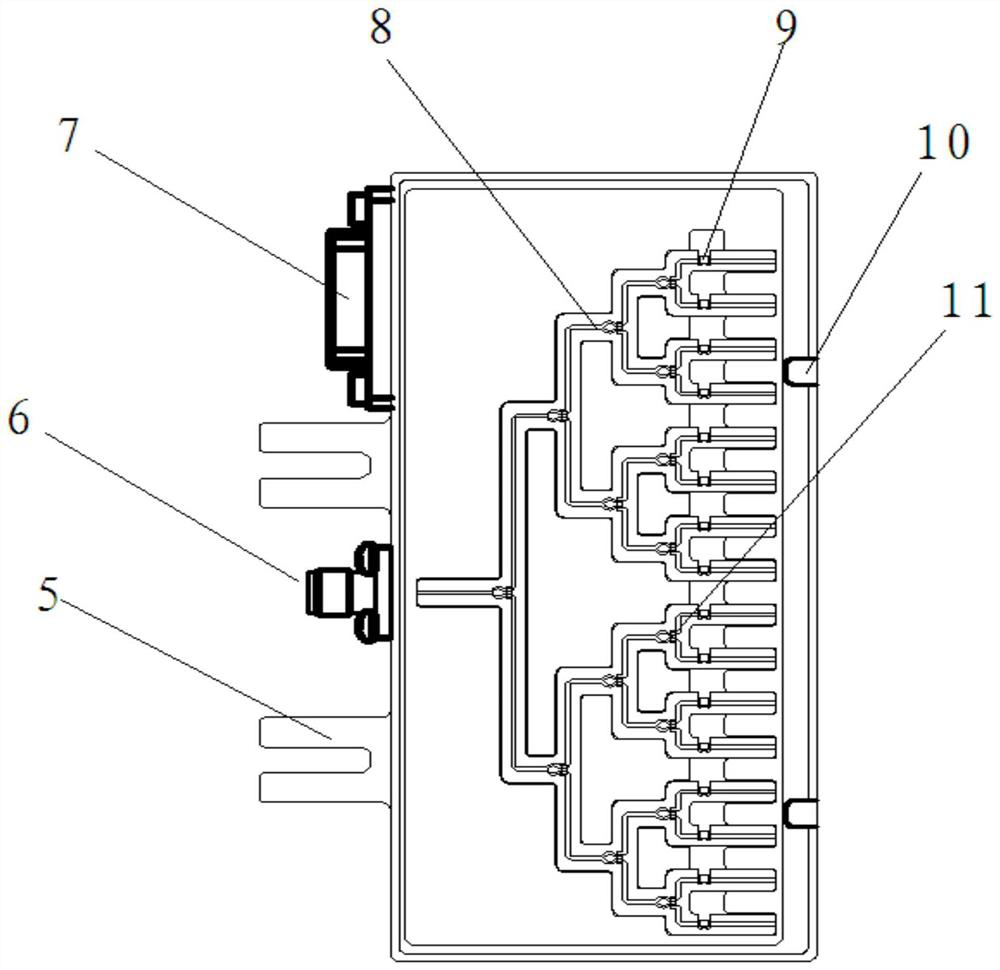

[0036] refer to figure 1 ,Such as figure 1 Shown is a schematic structural diagram of the multi-beam component automa...

Embodiment 2

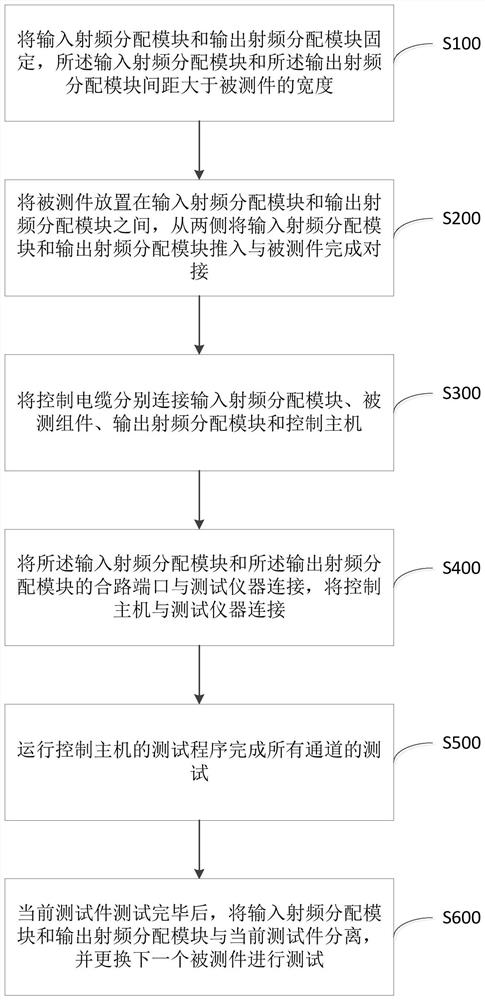

[0049] Based on the automatic test device for multi-beam components provided in the foregoing embodiments, this embodiment provides a method for automatically testing multi-beam components using the automatic test device. refer to image 3 ,Such as image 3 Shown is a schematic flowchart of a method for automatically testing a multi-beam component provided in this embodiment. The method specifically includes the following steps:

[0050] Step S100: Fix the input radio frequency distribution module and the output radio frequency distribution module, the distance between the input radio frequency distribution module and the output radio frequency distribution module is greater than the width of the component under test.

[0051] Specifically, the RF distribution module is first fixed on the support base with screws, only 1 or 2 screws are needed for installation, and after installation, there is no need to disassemble it during the entire subsequent testing process.

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com