Use method of electronic chip fixing device with overload protection structure

A technology for electronic chips and fixing devices, which is applied in the field of electronic chip fixing devices with overload protection structures, can solve problems such as easy blockage of filter screens and ineffective heat dissipation operations, and achieve the effect of protecting normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

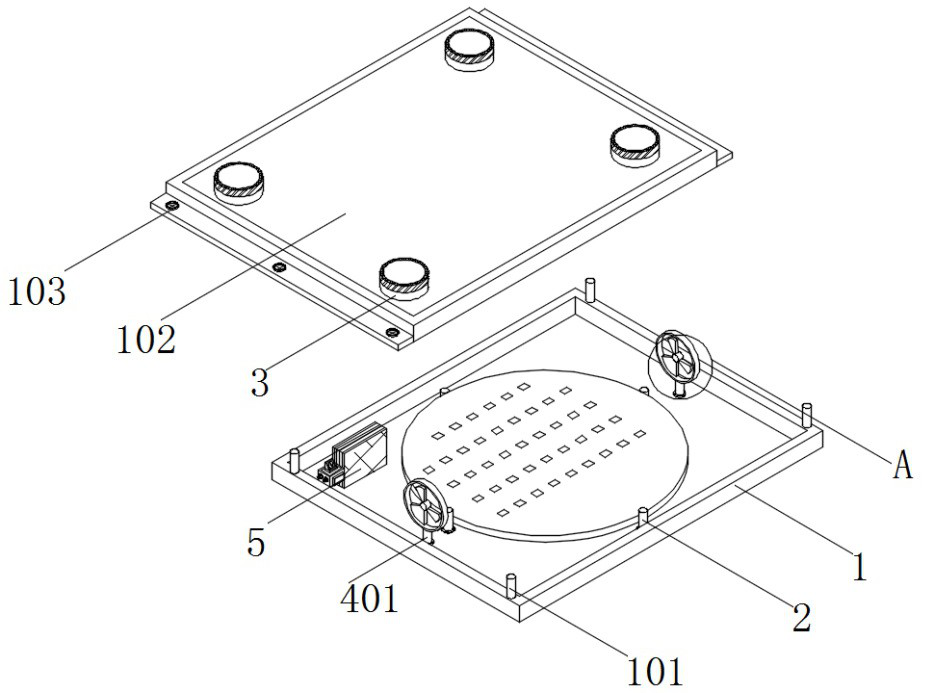

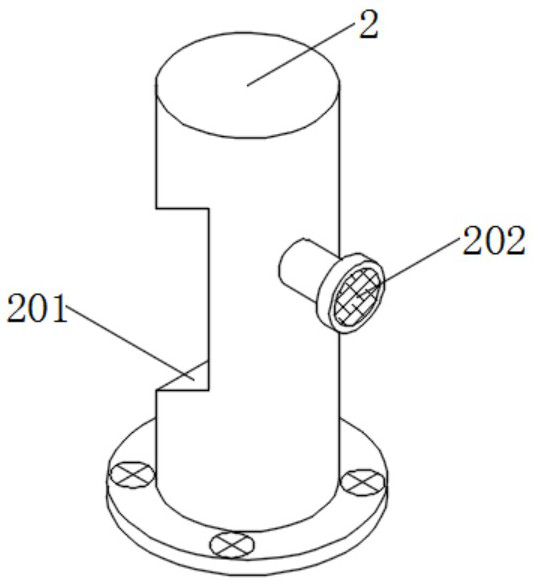

[0045] see figure 1 with Image 6 , an embodiment provided by the present invention: a method for using an electronic chip fixing device with an overload protection structure, comprising a protective housing 1 and an overload protection unit 5, the inner bottom wall of the protective housing 1 is equipped with an overload protection unit 5, And the overload protection unit 5 is located at the rear of one of the turntables 4, the overload protection unit 5 includes a diode plate 501, an ammeter 502, a rectifier 503 and a commutator 504, and a rectifier 503 is installed on the surface of the diode plate 501, and the rectifier 503 An ammeter 502 is installed on the top, and a commutator 504 is installed on the front of the rectifier 503;

[0046] The output terminal of the ammeter 502 is electrically connected to the input terminal of the rectifier 503 , the output terminal of the rectifier 503 is connected to the input terminal of the commutator 504 , and the output terminal of...

Embodiment 2

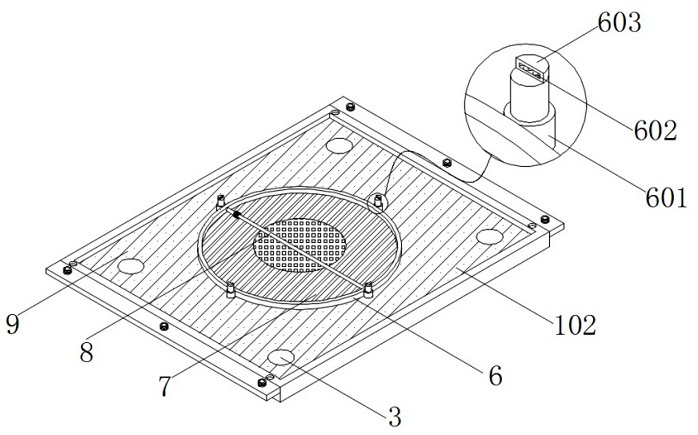

[0050] see figure 1 , Figure 7 with Figure 8 , an embodiment provided by the present invention: a method of using an electronic chip fixing device with an overload protection structure, including a rust removal slide bar 8 and a dust collection frame plate 7, and the inner wall of the limit hoop 6 is installed with a symmetrical arrangement The iron plate 805 of two groups of iron plates 805 is installed with derusting slide bar 8 on the surface close to each other, and the surface of derusting slide bar 8 is slidingly sleeved with slide block 802, and the surface of slide block 802 is surrounded with sandpaper layer 801, and The length of sandpaper layer 801 is less than the length of slide block 802, and the surface of slide block 802 is equipped with laser rangefinder 804, and laser rangefinder 804 is positioned at the side of sandpaper layer 801, and the surface of both sides of slide block 802 is all installed with etc. The electromagnetic column 803 arranged at a dis...

Embodiment 3

[0056] see figure 2 , an embodiment provided by the present invention: a method of using an electronic chip fixing device with an overload protection structure, including a limit hoop 6, a fitting 101 is installed on the top of the frame of the protective shell 1, and the protective shell 1 The top is connected with a top cover 102 through a fitting 101, and the inner top wall of the top cover 102 is equipped with a limit hoop 6, and the surface of the limit hoop 6 is equidistantly equipped with an electric telescopic rod 601, and the bottom of the electric telescopic rod 601 A semicircular clamping block 603 is installed, and the rectangular surface of the clamping block 603 is fitted with an indented pressure sensor 602 .

[0057] Both side outer walls of the top cover 102 are provided with connecting plates 103 , and connecting bolts are installed inside the connecting plates 103 .

[0058] Specifically, the fitting connection between the protective shell 1 and the top co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com