Coolant oil for heavy-load type vehicles

A heavy duty, coolant technology for cooling oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

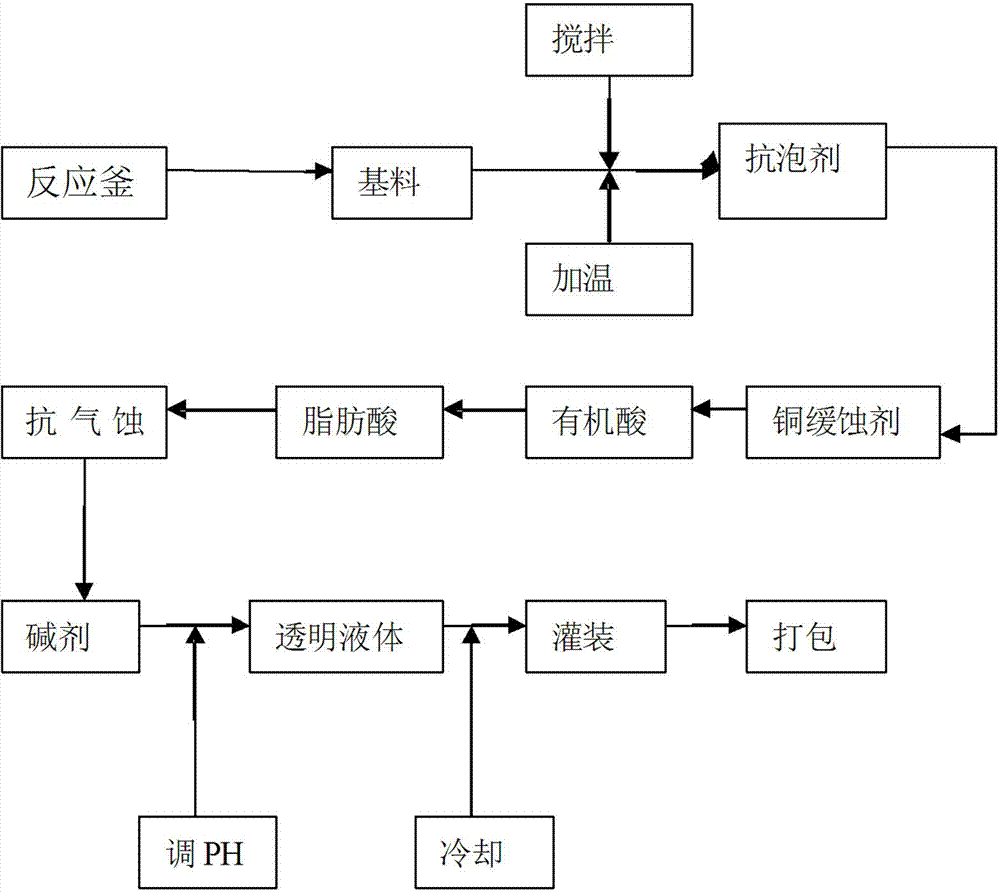

[0010] Such as figure 1 The coolant oil used in a heavy-duty car is mixed and stirred with 1000g of ethylene glycol, 300-500g of deionized water, and 5-15g of triethanolamine, and heated to 90°-100° during the stirring process to obtain a mixed solution 1 , add 0.5-10g of anti-foaming agent to mixed solution 1, copper corrosion agent: 2-4g of benzotriazole, organic acid: 5-10g of phosphoric acid, fatty acid: 0.2-5g of polyacrylic acid, anti-cavitation: 0.2-5g of borax Afterwards, carry out sufficient stirring to obtain the mixed solution 2, add alkali agent: NaOH3-5g in the mixed solution 2, adjust the pH value of the solution to 7 to obtain the mixed solution 3, filter the mixed solution 3 until it is transparent, and wait for the solution to be cooled and then canned to obtain finished product.

[0011] 1. Technology of Controlling Low Freezing Point and Reasonable Boiling Point

[0012] We use glycerol as one of the base materials. By adding other base materials, accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com