Ultrasonic-assisted stamping device with overload buffering protection function

An overload protection, ultrasonic-assisted technology, used in forming tools, manufacturing tools, fluids that utilize vibration, etc., can solve the problems of difficult quality assurance, labor-intensive labor, and damage to processed workpieces, and achieve easy installation and replacement. Conducive to taking out workpieces and wide range of engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

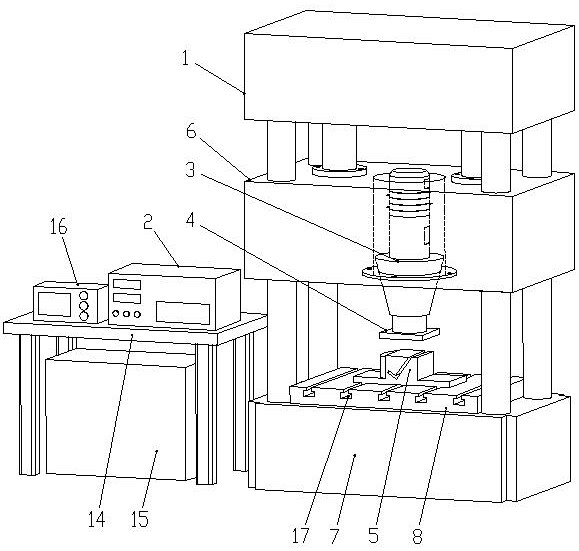

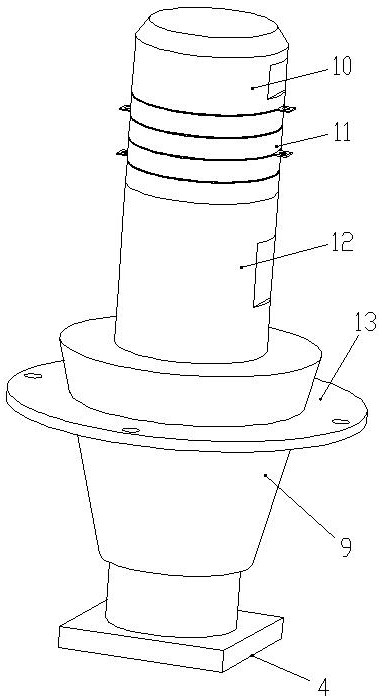

[0029] Example 1: as Figure 1-Figure 4 As shown, an ultrasonic auxiliary punching device with buffer overload protection of the present invention includes a hydraulic punching machine 1, an ultrasonic generator 2, an ultrasonic vibration assembly 3, a punching head 4 and a punching die 5, and a punching lifting platform of the hydraulic punching machine 1. 6. A mounting hole is vertically opened in the center. The ultrasonic vibration component 3 is arranged in the mounting hole and is fixedly connected to the punching and lifting platform 6 through the bolt component. The lower end of the ultrasonic vibration component 3 extends downward from the punching and lifting platform 6. There is a buffer overload protection mechanism 7, the punching table 8 of the hydraulic punching machine 1 is arranged on the top of the buffer overload protection mechanism 7, the punching table 8 is provided with a replaceable punching die 5, and the punching head 4 is arranged on the lower end of ...

Embodiment 2

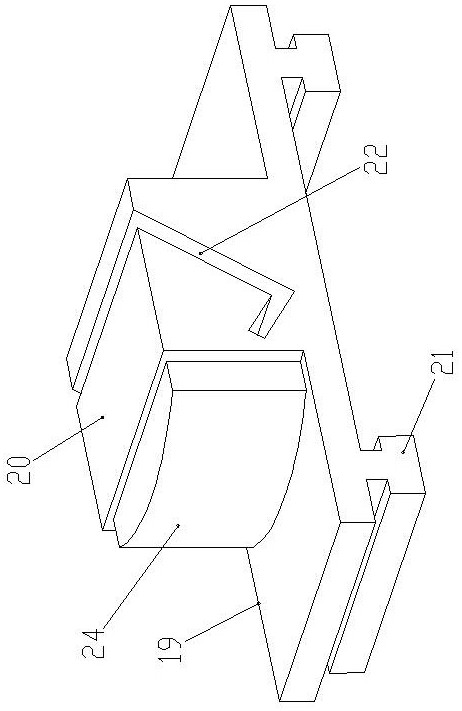

[0042] Embodiment 2: as Figure 5 As shown, the difference from the first embodiment is that: the top surface of the die body 20 is provided with a U-shaped groove 31, and the left and right sides of the stamping die 5 are welded with a second buffer plate 32 and a third buffer plate made of high manganese steel. The buffer plate 33, the second buffer plate 32 and the third buffer plate 33 are all arranged vertically. The lower sides of the second buffer plate 32 and the third buffer plate 33 are welded to the upper surface of the support plate 19. The side elevations of the three buffer plates 33 are respectively welded to the opposite sides of the mold body 20 , and the side surfaces of the mold body 20 are provided with buffer semicircular grooves 34 where they contact the second buffer plate 32 or the third buffer plate 33 .

[0043] The U-shaped groove 31 provided on the top surface of the mold body 20 is used for stamping and processing U-shaped sheet metal parts. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com