Mechanical bionic absorption filler and manufacturing method

A filler and mechanics technology, applied in the field of mechanical bionic absorption filler and production, can solve the problems of easy formation of agglomerates, nodules, mechanical incompatibility, and failure to achieve expected effects, and achieve the effect of easy injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

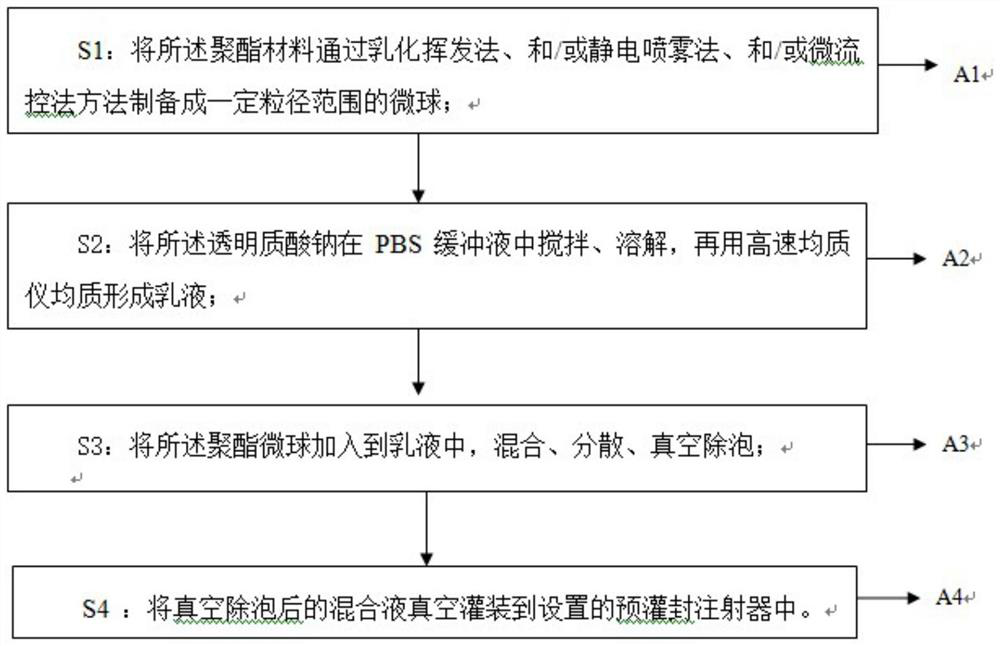

[0041] S1. Add sodium hyaluronate powder with a molecular weight of 1.58 million and 2.2 parts by weight into PBS buffer solution with a mass part of 62.8, and stir for 2 hours at a stirring speed of 150 rpm to completely dissolve sodium hyaluronate in PBS buffer solution middle;

[0042] S2. Pour the dissolved solution into a mixing instrument, add 35 parts by mass of PCL microspheres with a particle size range of 40 to 50 microns, and stir while homogeneously shearing for 30 minutes at a stirring speed of 100 rpm. Speed 10000rpm;

[0043] Turn off the homogeneous shear, turn on the vacuum pump, and evacuate the vacuum in the container to below -0.08MPa, keep it for 2 hours, eliminate air bubbles and mix evenly;

Embodiment 2

[0045] S1. Add sodium hyaluronate powder with a molecular weight of 2 million and 2 parts by weight to normal saline with a mass part of 88, and stir for 2 hours at a stirring speed of 150 rpm, so that the sodium hyaluronate is completely dissolved in the normal saline;

[0046] S2. Pour the dissolved solution into a mixing instrument, add 10 parts by mass of PLGA microspheres with a particle size range of 10 to 45 microns, and stir while homogeneously shearing for 30 minutes at a stirring speed of 100 rpm. Speed 10000rpm;

[0047] Turn off the homogeneous shear, turn on the vacuum pump, and evacuate the vacuum in the container to below -0.08MPa, keep it for 2 hours, eliminate air bubbles and mix evenly;

Embodiment 3

[0049] S1. Add sodium hyaluronate powder with a molecular weight of 3 million and a weight part of 1.2 to a PBS buffer solution with a mass part of 73.8, and stir for 2 hours at a stirring speed of 150 rpm to completely dissolve the sodium hyaluronate in the PBS buffer solution middle;

[0050] S2. Pour the dissolved solution into a mixing instrument, add 25 parts by mass of PGCL microspheres with a particle size range of 20 to 75 microns, and stir while homogeneously shearing for 30 minutes at a stirring speed of 100 rpm. Speed 10000rpm;

[0051] Turn off the homogeneous shear, turn on the vacuum pump, and evacuate the vacuum in the container to below -0.08MPa, keep it for 2 hours, eliminate air bubbles and mix evenly;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com