Amorphous calcium phosphate carboxymethyl chitosan nano-cluster material with ultra-small particle size and method

A technology of calcium phosphate carboxymethyl chitosan and carboxymethyl chitosan, which is applied in the field of bone implant materials to achieve the effects of facilitating injection, regulating polarization, and temperature-sensitive fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the present embodiment, a kind of ultra-small particle size amorphous calcium phosphate carboxymethyl chitosan nanocluster material is prepared, and the preparation method is as follows:

[0030] S1: Dissolve 0.1mL of 1M anhydrous calcium chloride (CaCl 2 ) solution was slowly dropped into 0.15 mL of polyaspartic acid (PASP) solution with a concentration of 0.3 g / mL, stirred at a speed of 500 rpm for 10 min to fully react, and solution A was obtained.

[0031] During this reaction, PASP acts as an anionic polymer, and the carboxyl group on its side chain can chelate Ca 2+ , forming polyaspartate, thereby stabilizing Ca 2+ .

[0032] S2: Slowly add the solution A obtained in S1 to 2 mL of carboxymethyl chitosan (CMC) solution with a concentration of 100 mg / mL, and stir overnight at a speed of 500 rpm (that is, at least 6 h) to make it fully react , to obtain solution B.

[0033] In this reaction process, since carboxymethyl chitosan (CMC) introduces carboxymethyl ...

Embodiment 2

[0038] In order to further study the performance of the ultra-small particle size amorphous calcium phosphate carboxymethyl chitosan nanocluster material prepared in Example 1, corresponding experiments were carried out in this example.

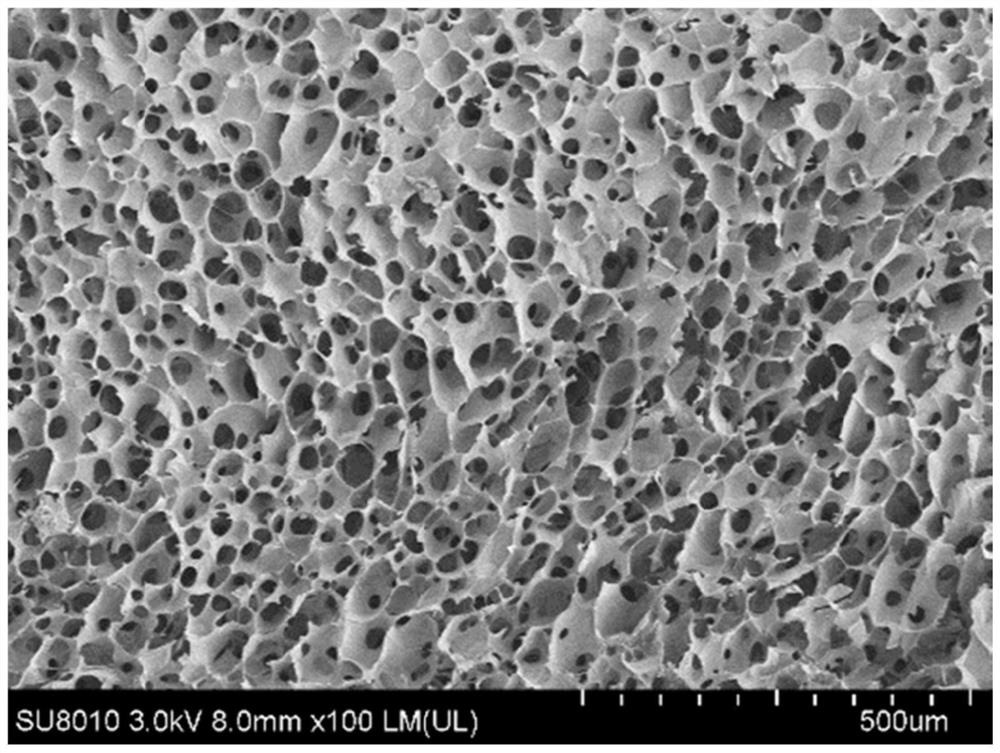

[0039] Such as figure 1 Shown is the scanning electron microscope image of the material after freeze-drying. It can be seen from the figure that the material is a three-dimensional porous network structure, and its voids are evenly distributed. The nano-scale voids are distributed with uniform micron-scale voids, which can simulate natural cells. The extracellular matrix supports cell migration and growth.

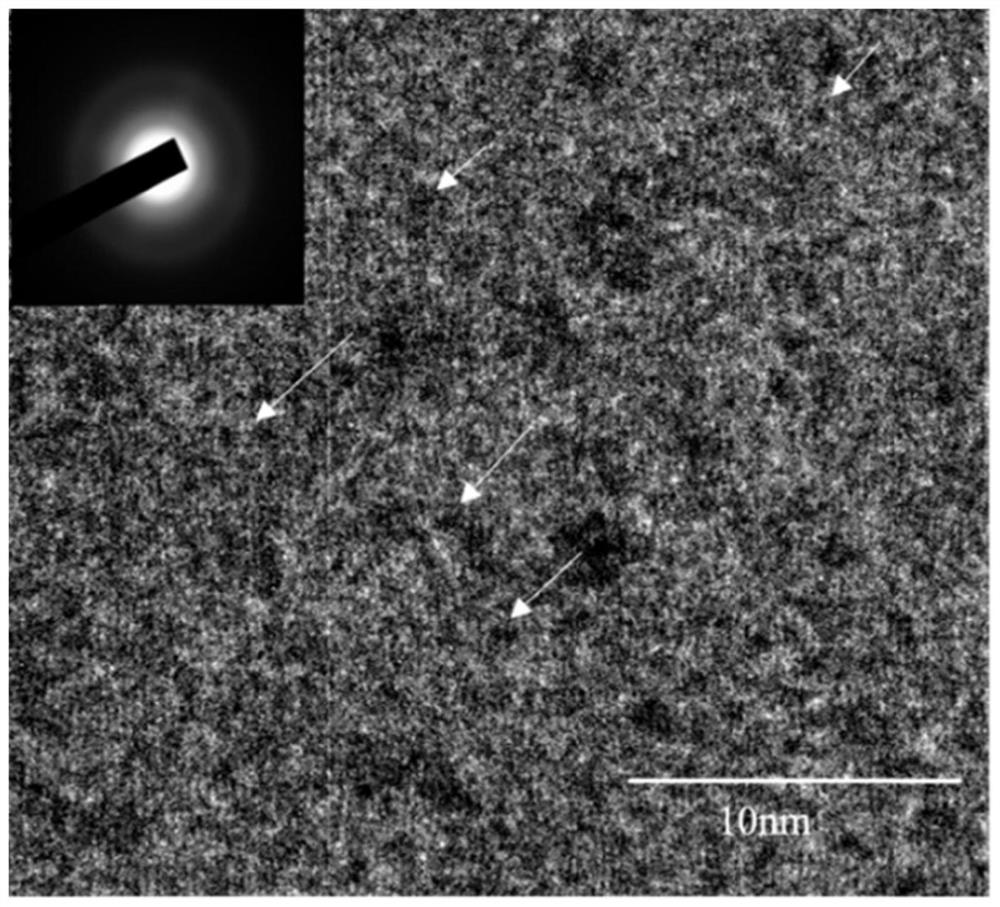

[0040] Such as figure 2 Shown is the transmission electron microscope image of the material solution, the upper left corner is the diffraction ring, and the white arrow points to the amorphous calcium phosphate particles. It can be seen from the figure that the material solution contains calcium phosphate particles of about 1 nm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com