Ingredient mixing device for mixed flour processing and use method thereof

A mixing device and flour technology, applied in the field of flour processing, can solve the problems of difficult to achieve automatic production, low processing efficiency, difficult to achieve quantitative feeding, etc., and achieve the effects of high production efficiency, convenient loading and unloading, and convenient adding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

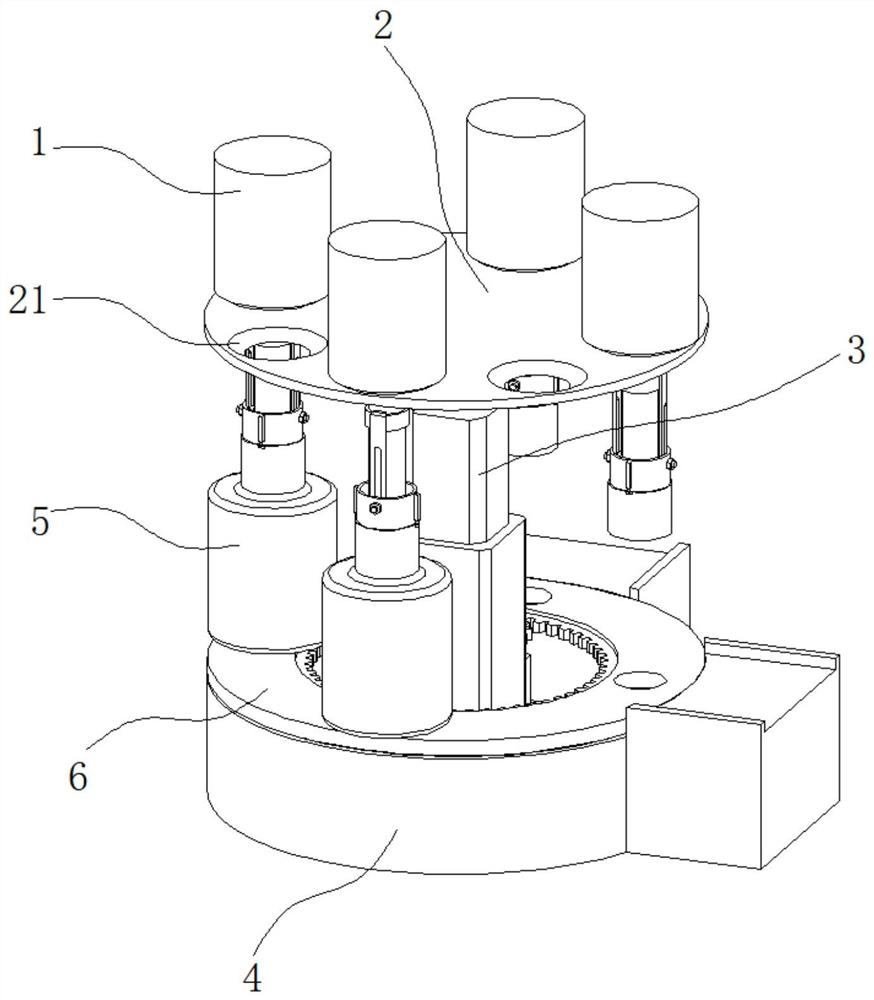

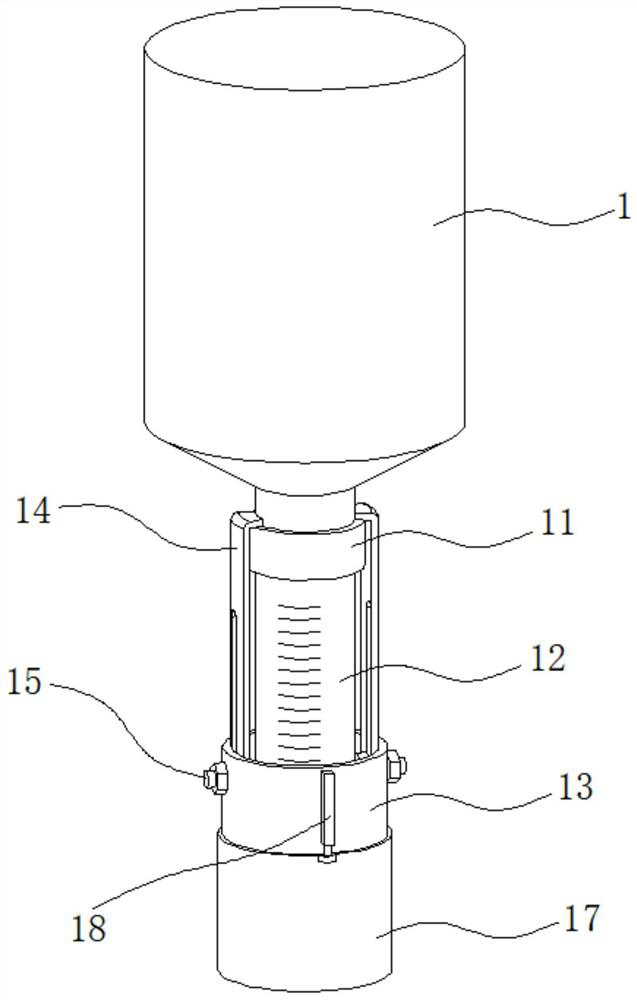

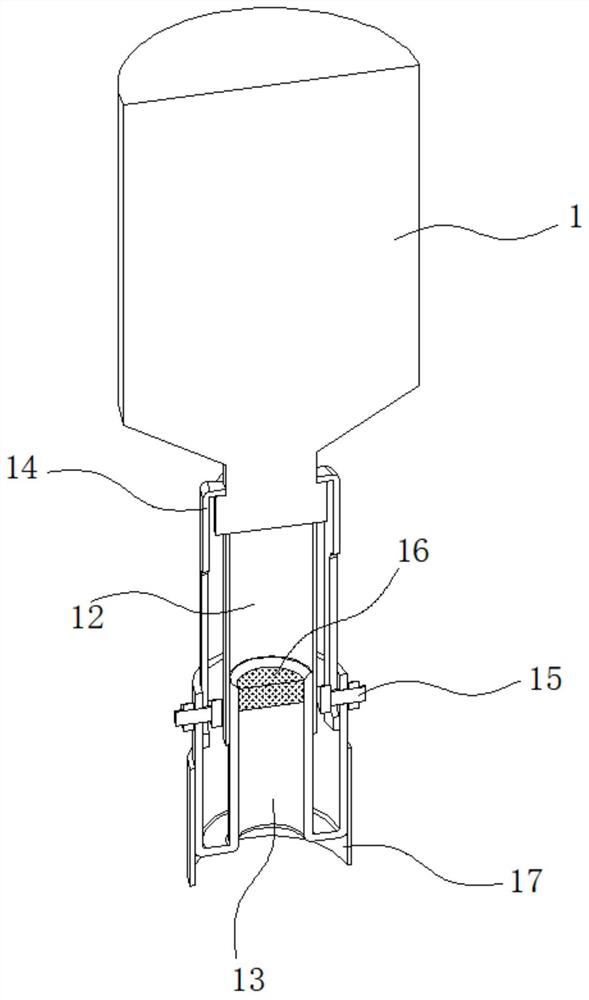

[0041] see figure 1 As shown, the present invention is an ingredient mixing device for mixing flour processing, comprising a batching cylinder 1, a circular turntable 2, a mixing cylinder 5 and a driving mechanism 6, and the edge of the circular turntable 2 is provided with a plurality of The batching cylinder 1, the edge of the circular turntable 2 is provided with a plurality of first positioning holes 21 evenly distributed along the circumference, the batching cylinder 1 is limited in the first positioning holes 21, the bottom rotating shaft of the circular turntable 2 and the first The output shaft of the motor 3 is fixedly connected, the first motor 3 is fixed on the support platform 4, the mixing cylinder 5 is arranged below the batching cylinder 1, the mixing cylinder 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com