One-time forming equipment for connecting rod seat fixing shaft

A forming equipment and fixed shaft technology, applied in the field of closed door fixed shaft processing equipment, can solve the problems of reduced processing efficiency, large waste of steel materials, long processing time, etc., to improve processing efficiency, reduce the use of steel and welding materials, and process The effect of step optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

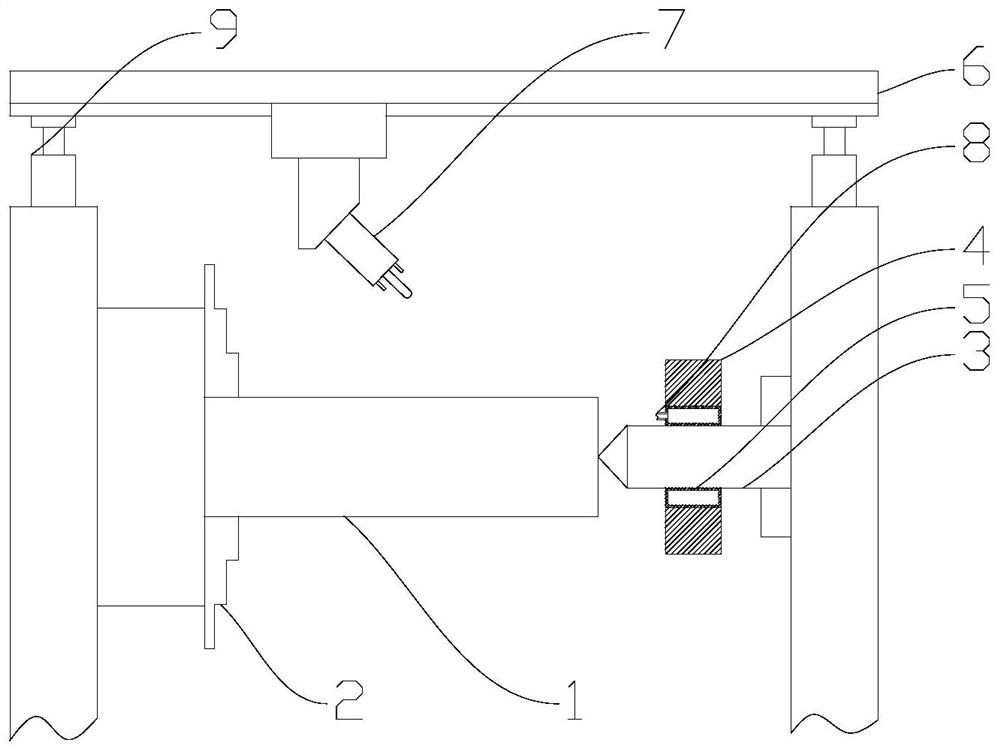

[0022] Such as figure 1 As shown, the one-time molding equipment for the fixed shaft of the connecting rod seat includes a cutting mechanism and a welding mechanism. The cutting mechanism is a machine tool, and the shaft body 1 is clamped between the chuck 2 and the thimble 3 of the machine tool, and is cut by the tool of the machine tool. , the sleeve 4 is sleeved on the thimble 3, the outer wall of the thimble 3 is provided with an air cushion 5, the air cushion 5 expands and holds the sleeve 4; the sleeve 4 can slide on the thimble 3, when the air cushion 5 After expansion, the gap between the sleeve body 4 and the thimble 3 is filled with the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com