Automatic monitoring method and system for concrete temperature and humidity curing

An automatic monitoring and concrete technology, applied in ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of difficult to meet the differentiated maintenance requirements of different varieties of concrete, different temperature and humidity requirements, and meet the differentiated maintenance requirements. , the effect of prolonging the corresponding curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

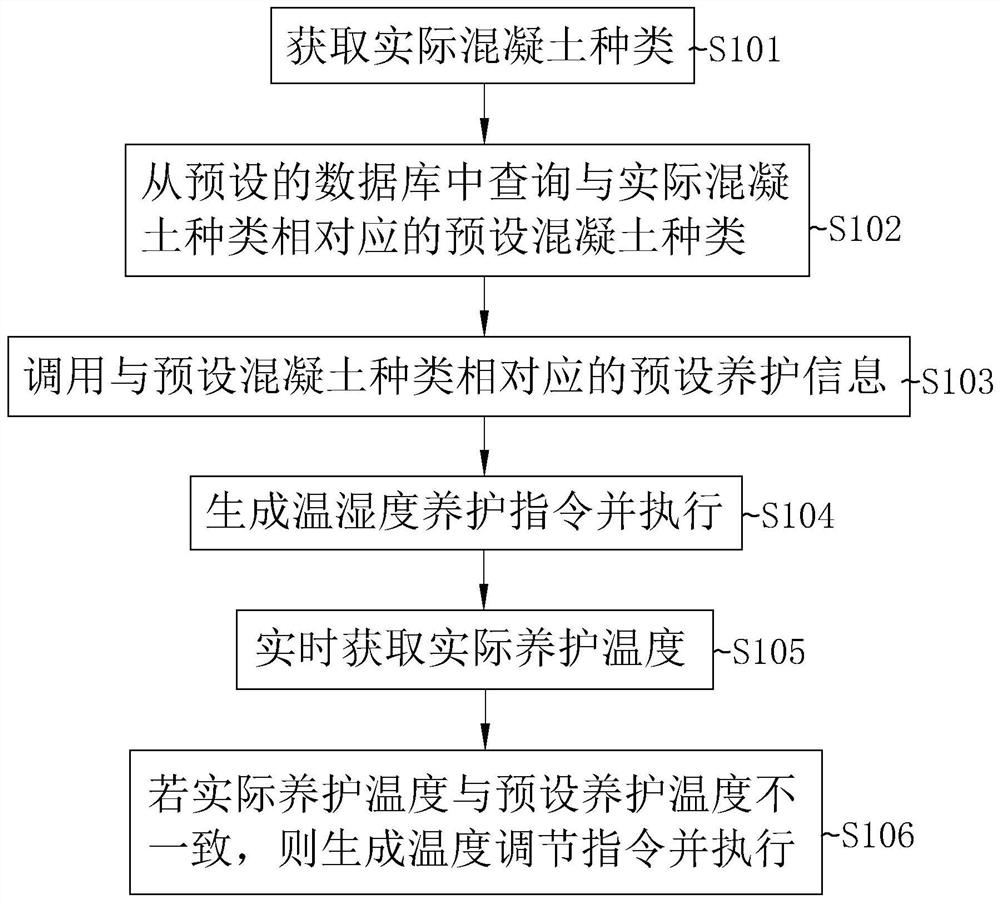

[0065] The following is attached Figure 1-6 The application is described in further detail.

[0066] The embodiment of the present application discloses an automatic monitoring method and system for concrete temperature and humidity maintenance.

[0067] refer to figure 1 , an automatic monitoring method for concrete temperature and humidity maintenance, comprising:

[0068] S101: Obtain the actual concrete type.

[0069] Specifically, before the curing device performs temperature and humidity curing operations on the concrete, the user inputs the current concrete type information through the touch screen set on the curing device, so that the monitoring system can obtain the actual concrete type of the currently cured concrete, which is convenient for monitoring The system makes specific plans for the follow-up maintenance operation of the curing device, and improves the temperature and humidity curing process of the curing device for different types of concrete.

[0070]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com