Wearing course for preventive maintenance technology and its construction method

A technology of preventive maintenance and wear layer, which is applied to the cohesive pavement paved on site, roads, roads, etc., can solve the problems of overlay cracking, durability reduction of ultra-thin wear layer, and peeling of the mixture, so as to improve the durability Fatigue performance, long curing time, effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

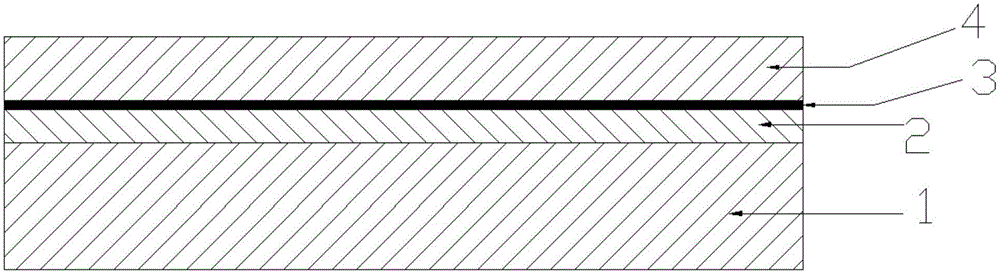

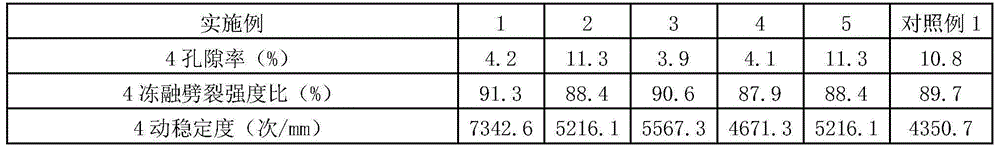

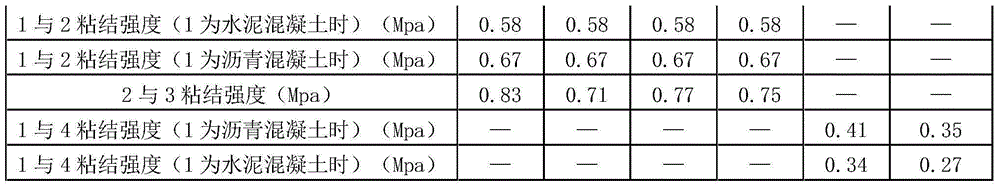

[0038] When the ultra-thin wearing layer 4 mixture design porosity is 3%-6%, discontinuous dense gradation, AH-70# matrix asphalt 80.7-87.8 parts, SBS modifier 2-3 parts, rubber powder 10-14 parts, 0-2 parts of compatibilizer and 0.2-0.3 parts of stabilizer form low-SBS high-rubber powder composite modified asphalt, which is in the nature of rubber powder modified asphalt, which can improve the high-temperature stability and crack resistance of the mixture, and can be combined with The stress absorbing layer 2 is closely bonded.

[0039] Raw material preparation:

[0040] (1) Material preparation for stress absorbing layer 2. Take 18 parts of 60-mesh rubber powder, 82 parts of base asphalt, and 0.25 parts of stabilizer. Heat the base asphalt to 180-190°C, put rubber powder into the base asphalt and stir for 2-3 hours, then add stabilizer and stir for 0.5 hours to prepare rubber powder modified asphalt. The manufacturing process is on-site modification, and the storage of ru...

Embodiment 2

[0059] When the design porosity of ultra-thin wearing layer 4 mixture is discontinuous and semi-open gradation greater than 10%, AH-70# base asphalt is 91.7-95.3 parts, SBS modifier is 3.5-4 parts, rubber powder is 1-4 parts, The stabilizer is 0.2-0.3 parts to form a high SBS low rubber powder composite modified asphalt, and the composite modified asphalt has the property of SBS modified asphalt (I-D). Low-volume rubber powder can also be used in intermittent dense graded mixtures.

[0060] (1) The material of the stress absorbing layer 2 is the same as that in Embodiment 1.

[0061] (2) Rubber powder modified asphalt adhesive layer 3 adopts the rubber powder modified asphalt of Example 1.

[0062] (3) Preparation of ultra-thin wear layer 4 materials. Take 93.1 parts of AH-70 asphalt, 3.7 parts of linear SBS modifier, 3 parts of rubber powder, and 0.2 parts of stabilizer. The base asphalt is divided into groups A, B and C, group A: group B: group C = 1: 0.6-0.7: 0.6-0.7. A...

Embodiment 3

[0073] Ultra-thin wearing layer 4 mixture design porosity of 3%-6% discontinuous dense gradation, AH-70# base asphalt 93.8 parts, SBS modifier 4 parts, rubber powder 2 parts, stabilizer 0.2 parts, Group A 42, group B 25.9, C group 25.9. Others were carried out according to Example 2 to obtain composite modified asphalt.

[0074] (1) The material of the stress absorbing layer 2 is the same as that in Embodiment 1.

[0075] (2) The rubber powder modified asphalt of Example 1 is used for the bonding layer.

[0076] (3) Preparation of ultra-thin wear layer 4 materials. The ultra-thin wearing layer 4 includes 5.9 parts of composite modified asphalt, 100 parts of aggregate, 10 parts of filler, and 0.3 part of fiber. Aggregate includes 85 parts of coarse aggregate and 15 parts of fine aggregate.

[0077] Construction method:

[0078] The construction method of the stress absorption layer 2 and the rubber powder modified asphalt adhesive layer 3 is the same as that of the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com