Corrosion-resistant and anti-seepage concrete material and preparation method thereof

A concrete and corrosion-resistant technology, which is applied in the field of concrete materials, can solve the problems of affecting the anti-seepage and durability of concrete, the reduction of concrete anti-seepage performance, and the difficulty of completely eliminating pores, so as to achieve excellent anti-seepage performance and corrosion resistance. Anti-seepage performance and corrosion resistance, good plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

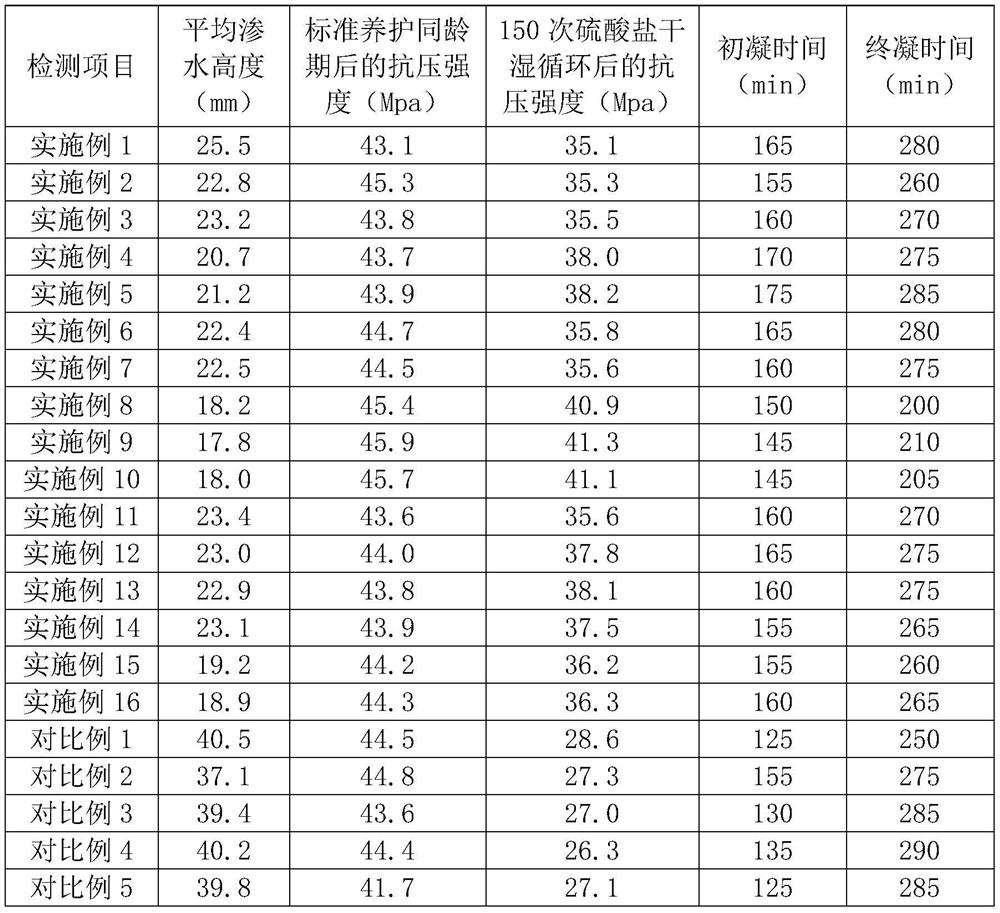

Embodiment 1-3

[0046] Step 1, according to Table 2, take the mineral admixture and magnesia of corresponding weight parts, and stir at normal temperature and pressure for 5 minutes with a rotating speed of 60r / min to obtain the admixture component 1;

[0047] Step 2, according to Table 2, take corresponding weight parts of nano-sulfur and polysiloxane defoamer, and stir for 30 minutes at normal temperature and pressure with a rotation speed of 80r / min, to obtain admixture component 2;

[0048] Step 3: Put the admixture component 1, the admixture component 2 and other raw materials in a mixer, and stir for 30 minutes at a speed of 60 r / min at normal temperature and pressure to prepare a corrosion-resistant and anti-seepage concrete material.

[0049] The mineral admixture used in Examples 1-3 is fly ash, and the polysiloxane defoamer is hexamethyldisiloxane, octamethylcyclotetrasiloxane and dodecamethylcyclohexasiloxane Alkanes are composed according to the ratio of 1:1:1 by weight, and the d...

Embodiment 4

[0054] The only difference between this embodiment and Example 3 is that the polysiloxane defoamer is hexamethyldisiloxane, octamethylcyclotetrasiloxane and dodecamethylcyclohexasiloxane in parts by weight 1 :1.2:0.8 ratio composition.

Embodiment 5

[0056] The only difference between this embodiment and Example 3 is that the polysiloxane defoamer is hexamethyldisiloxane, octamethylcyclotetrasiloxane and dodecamethylcyclohexasiloxane in parts by weight 1 :1.5:0.5 ratio composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com