Vehicle lower body structure

A body and vehicle technology, applied to the substructure, vehicle components, superstructure, etc., can solve the problems of deformation of the cabin, inability to collide with the load transfer dispersion, collapse of the lower side beam section, etc., to ensure the effect of impact energy absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

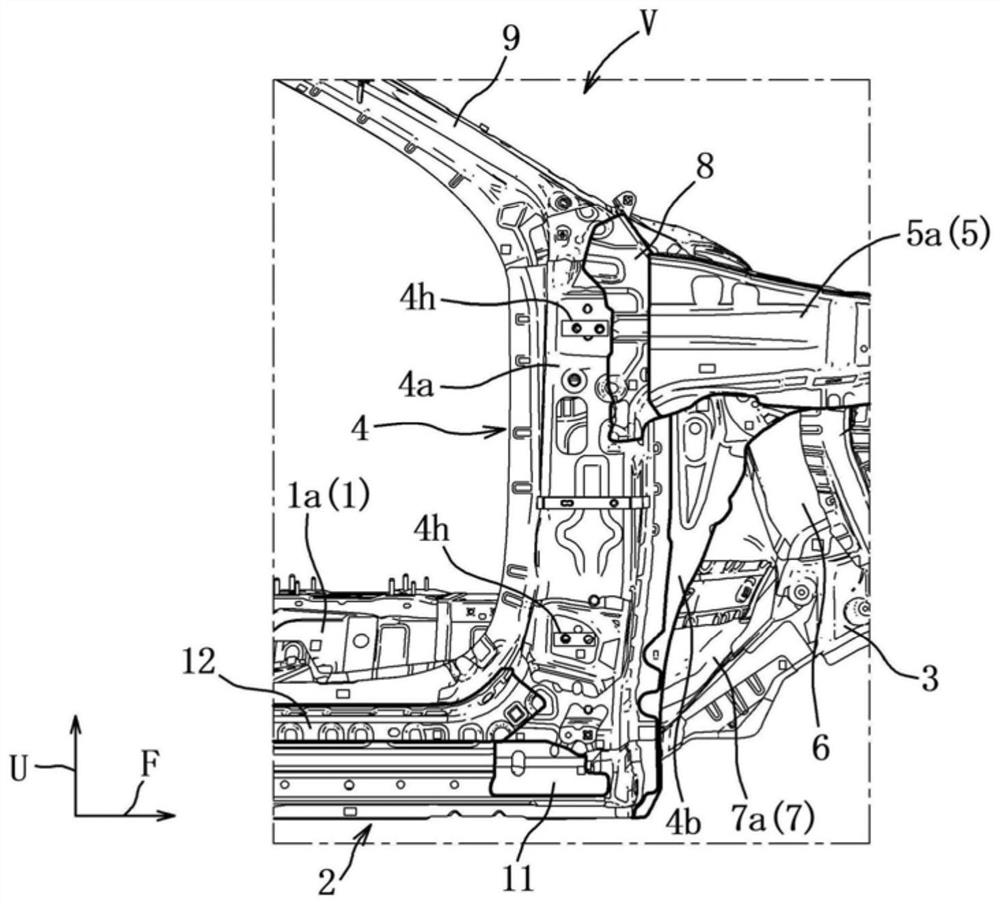

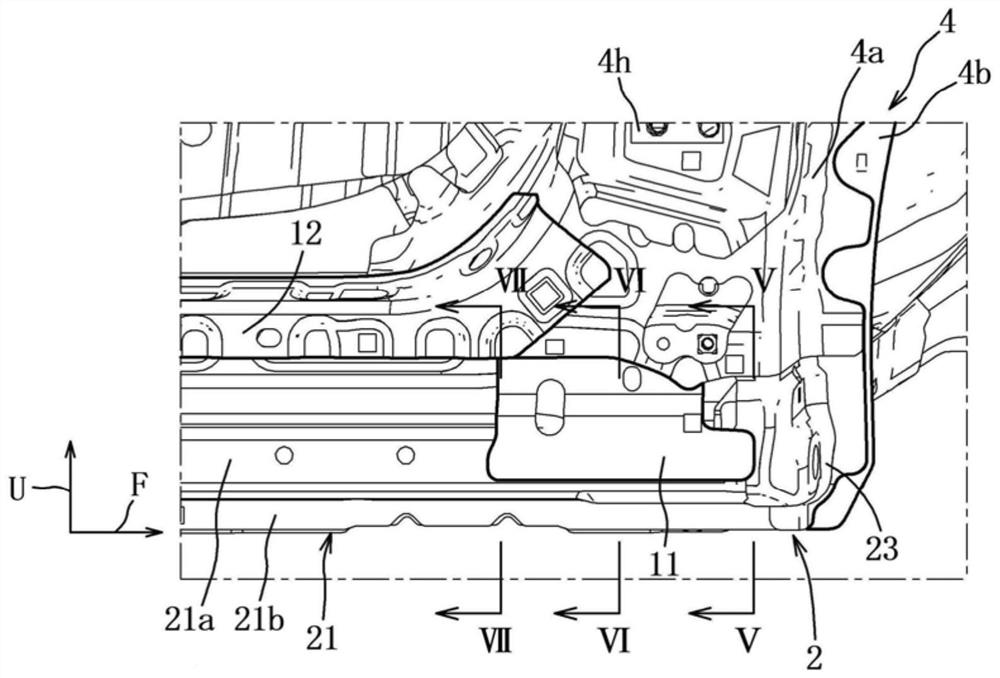

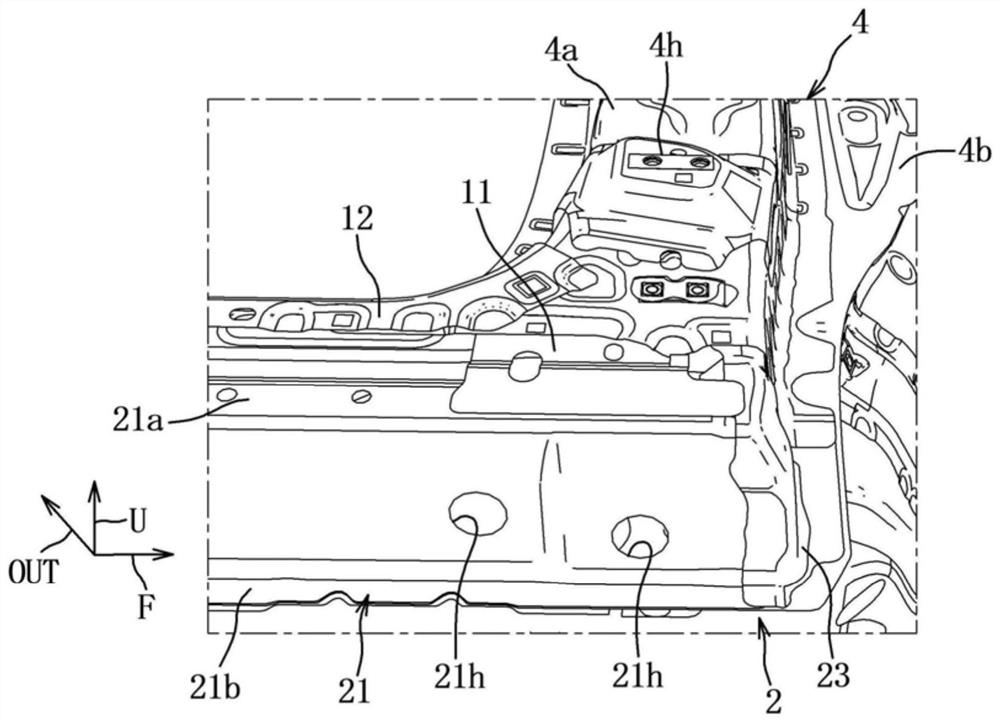

[0075] Below, based on Figure 1 to Figure 11 Example 1 of the present invention will be described.

[0076] Such as figure 1 As shown, the vehicle V includes: a floor panel 1 forming a tunnel portion 1a and constituting the bottom surface of the vehicle compartment; a pair of left and right side sills 2 extending forward and backward; A dash panel (not shown), a pair of left and right front longitudinal frames 3 extending forward from the dash panel, a pair of left and right hinge pillars 4 extending vertically upward from the front ends of the pair of side sills 2, And a pair of left and right skirt reinforcements 5 extending forward from the upper end portions of the pair of hinge posts 4 and the like.

[0077] In this vehicle V, an impact energy absorbing mechanism is provided, and in the SORB (Small Overlap Rigid Barrier: Small Overlap Rigid Barrier) test, an obstacle and a portion (overlapping area) outside the front longitudinal frame 3 in the vehicle width direction ...

Embodiment 2

[0125] Next, based on Figure 12 , Figure 13 The reinforcing member 30A of the second embodiment will be described. In addition, the same code|symbol is attached|subjected to the same component as Example 1.

[0126] In Embodiment 1, the deformation suppressing portion 33 is composed of the first portion 33a, the third portion 33c perpendicular to the vehicle body front-rear direction, the second portion 33b, and the fourth portion 33d perpendicular to the vehicle width direction. In Embodiment 2, the deformation suppressing portion 33A is composed of a fifth portion 33e substantially perpendicular to the inner rear in the vehicle width direction.

[0127] Such as Figure 12 , Figure 13 As shown, the reinforcement member 30A has a front end reinforcement portion 31A, a deformation allowable portion 32A, and a deformation suppression portion 33A as main structural elements, and when a collision load toward the inner rear in the vehicle width direction is input to the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com