Aluminum stranded wire cutting tool for steel cored aluminum stranded wire end

A technology of aluminum steel-reinforced wire and cutting tools, which is applied in the field of aluminum-strand wire cutting tools at the ends of aluminum-reinforced steel-reinforced wires. The effect of enhancing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

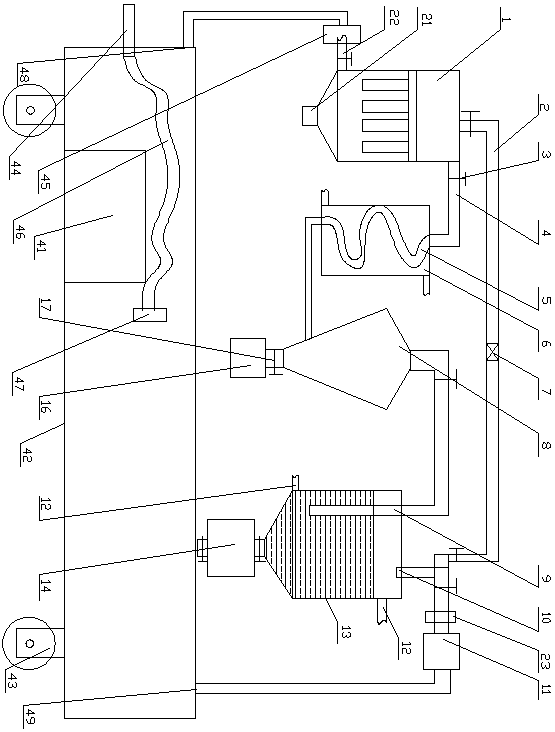

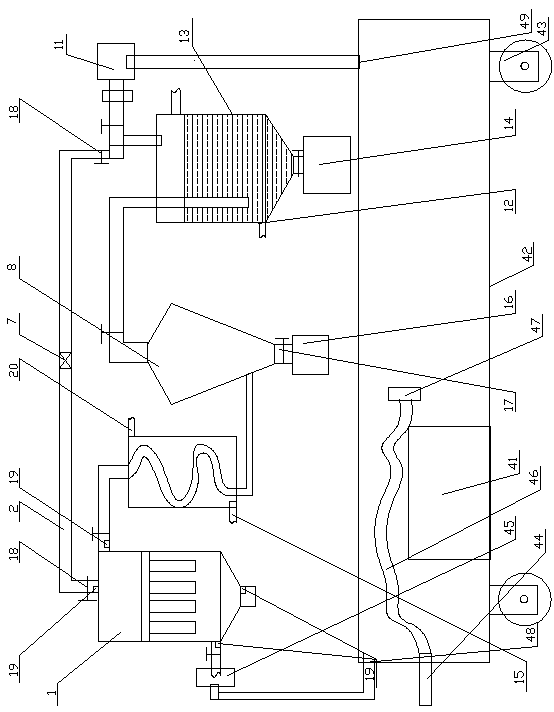

[0042] A steel core aluminum stranded wire end aluminum stranded wire cutting tool, including a box body and a cutting machine 41 arranged in the box body, a walking mechanism 43 is arranged under the box body 42, and a dust removal system is arranged on the box body, Described casing is provided with breathing mask 47, and described breathing mask is connected with casing inlet pipe 44 by flexible pipe 46, and the air outlet 48 of described casing is connected with the air inlet of blower, and the air outlet of described blower 45 It is connected with the first air intake pipe 22, and the exhaust mechanism 11 is connected with the air inlet 49 of the box body. The first regeneration mechanism connected to the second end of the first dust removal mechanism, the settling mechanism connected to the energy conversion mechanism, the dust accumulation module arranged at the lower part of the settling mechanism, the absorbing mechanism arranged at the rear of the settling mechanism ...

Embodiment 2

[0054] Embodiment 2, which is different from Embodiment 1 in that: the regeneration pipeline 2, the regeneration discharge pipe 21, and the first air intake pipe 22 are all equipped with a detection module 19;

[0055] The detection module 19 includes a flow rate sensor 192 , a dust sensor 191 and a temperature sensor 193 .

[0056] The first regeneration mechanism adopted in this embodiment includes a regeneration pipeline communicated with the exhaust mechanism, solenoid valves arranged at both ends of the regeneration pipeline, a regeneration supercharger arranged in the middle of the regeneration pipeline, and The regeneration discharge pipe arranged at the lower part of the dust collector; the airflow can be pressurized by the regeneration supercharger to ensure that there is a high-speed airflow to clean the dust collector during backflushing and dust removal, which can greatly reduce the amount of backflushing gas. To ensure the overall cleaning effect; the energy conve...

Embodiment 3

[0057] Embodiment 3: The difference between it and Embodiment 2 is that: the first dust removal mechanism, the energy conversion mechanism, the first regeneration mechanism, the sedimentation mechanism, the dust accumulation module, the absorption mechanism, the exhaust mechanism, the circulation mechanism, and the unloading module are all Signal interconnection with the control module arranged on the outer wall of the dust collector;

[0058] The control module is PLC or personal computer.

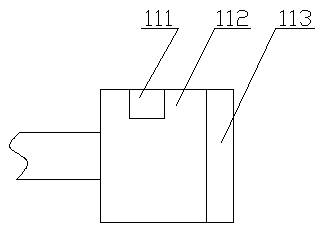

[0059] The adsorption turntable includes two ring-shaped sealing plates 231, a cylindrical channel 232 that is arranged between the two ring-shaped sealing plates 231 and matches the discharge pipe, and connects the mandrel 237 with the ring. A plurality of support arms 233 between the shaped sealing plates 231;

[0060]The adsorption module is arranged in the cylindrical channel 232, and the sealing ring 235 matched with the annular sealing plate 231 is arranged on the adsorption bayone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com