A prefabricated anti-collision guardrail

An anti-collision guardrail and prefabricated assembly technology, applied in the field of bridge structure, can solve the problems of high maintenance cost, large loss and large damage, and achieve the effect of prolonging the impact time, reducing the degree of damage, and ensuring consumption and absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

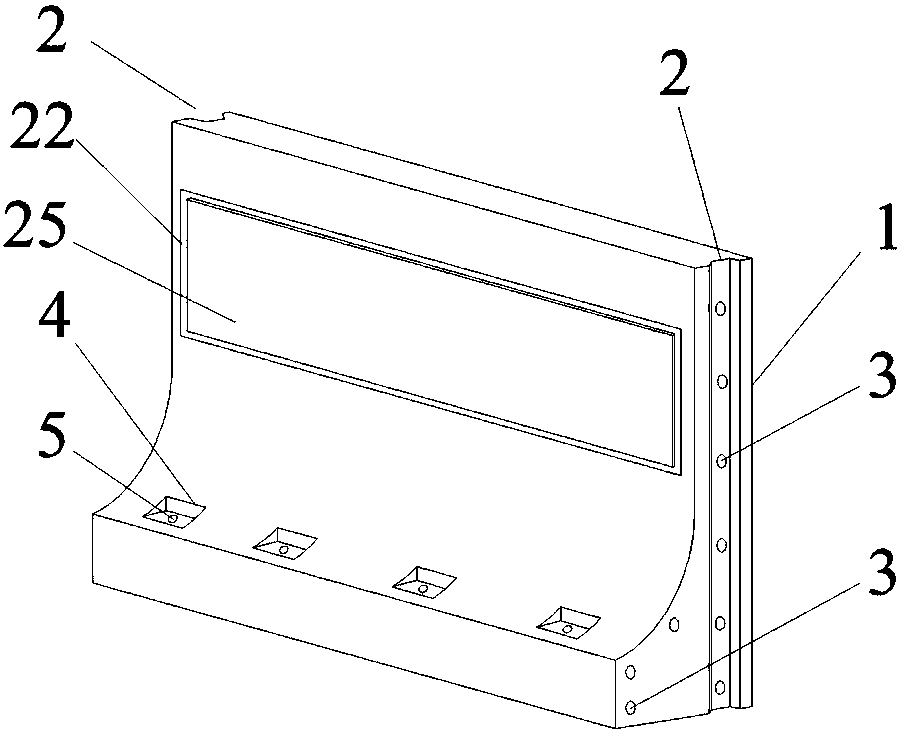

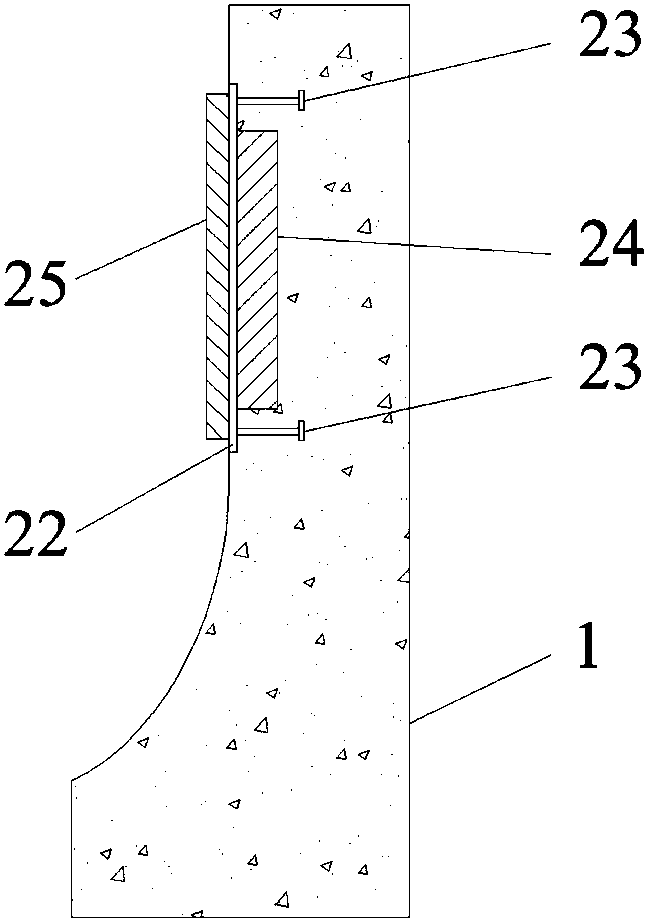

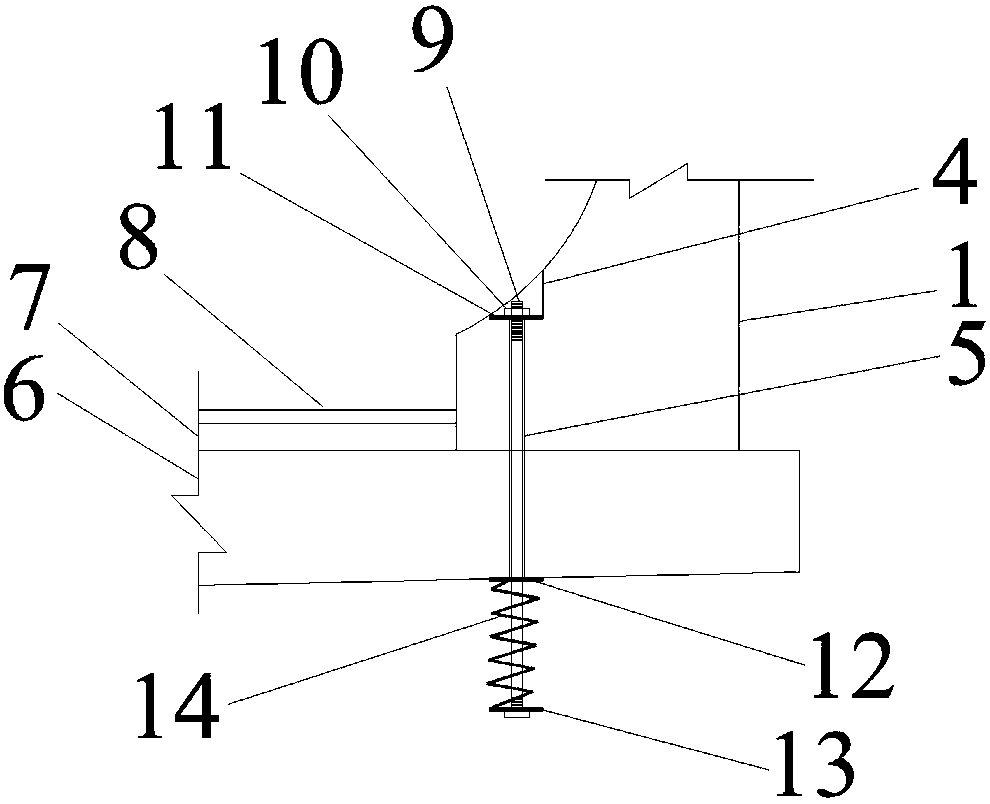

[0016] The schematic diagram corresponding to this embodiment is shown in figure 1 , figure 2 and image 3 . The crash barrier 1 of the present invention is assembled from concrete prefabricated components. There are vertical connecting grooves 2 at both ends of the prefabricated components, and there are horizontal longitudinal connecting holes 3 along the longitudinal direction of the bridge in the connecting grooves 2. There are connecting steel bars in the corresponding reserved holes of the adjacent prefabricated components, and the adjacent prefabricated components Concrete is poured in the joints; there are anchor bolt grooves 4 in the lower part of the inner side of the prefabricated components, and there are vertical anchor bolt holes 5 inside, and there are also reserved holes in the corresponding positions of the bridge deck 6. , the crash barrier 1 is fixed on the bridge deck 6 by tightening the nut 10 . Half of the screw rod 9 is a long screw rod, which is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com