Steel wire rubber for tire based on isoprene rubber and tire rim based on isoprene rubber

A technology of isoprene rubber and trans isoprene rubber, applied in the field of tire rims, can solve the problems that limit the development and application of steel wire rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

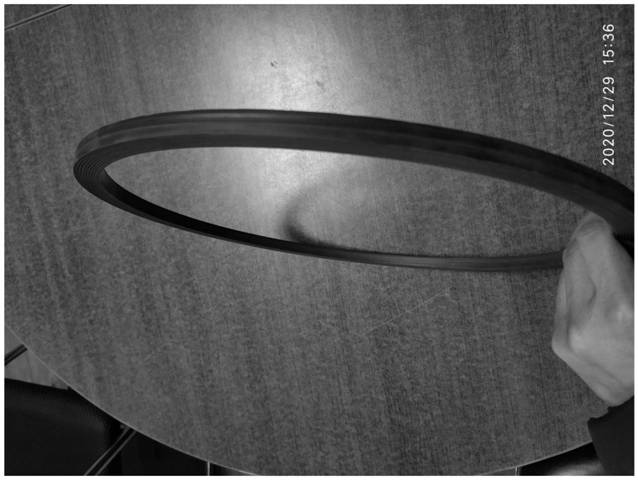

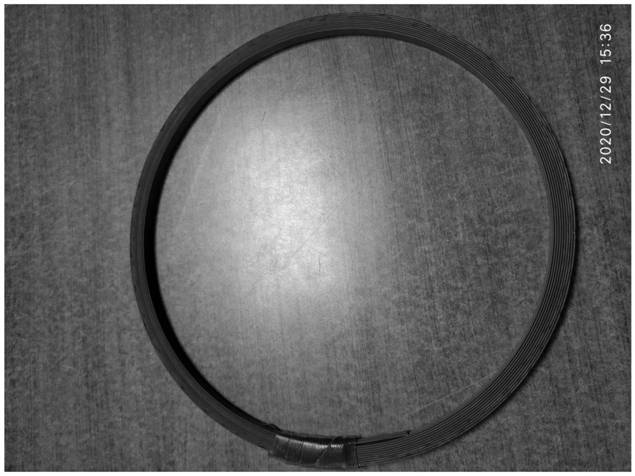

Image

Examples

Embodiment 1~3

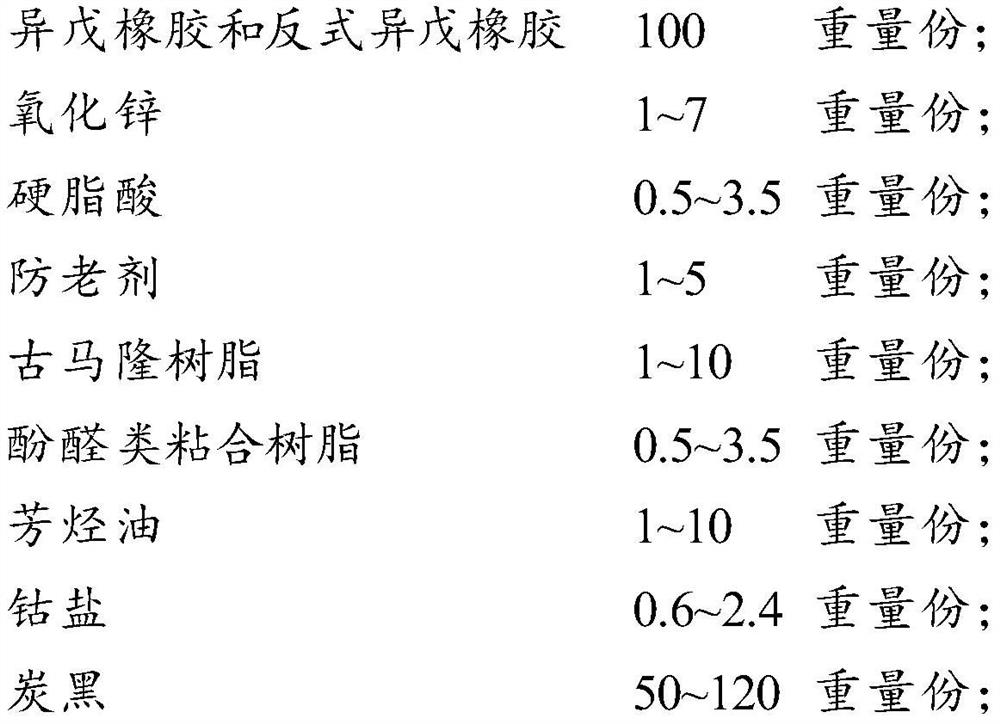

[0077] In the mixing process of steel wire glue, first put isoprene gum and trans-type isoprene gum, traditional Chinese medicine (including zinc oxide, stearic acid, anti-aging agent, coumarone resin, binding resin, cobalt) in the internal mixer in sequence. Salt), carbon black and aromatic oil, debinding at a temperature not higher than 170°C to obtain masterbatch. Then put the masterbatch and small medicine (including resin curing agent, accelerator, sulfur) in the internal mixer below 70°C in sequence, and then discharge the glue at a temperature not higher than 110°C to obtain steel wire glue .

[0078] Referring to Table 1, Table 1 is the formula of steel silk glue in Examples 1-3 of the present invention.

[0079] Table 1

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com