Heating cooker

A cooker and heating device technology, applied in heating methods, electric heating fuel, lighting and heating equipment, etc., can solve problems such as overheating of internal components, unreasonable air duct design, power-off protection, etc., to increase air volume and wind Pressure, to avoid the effect of excessive local temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

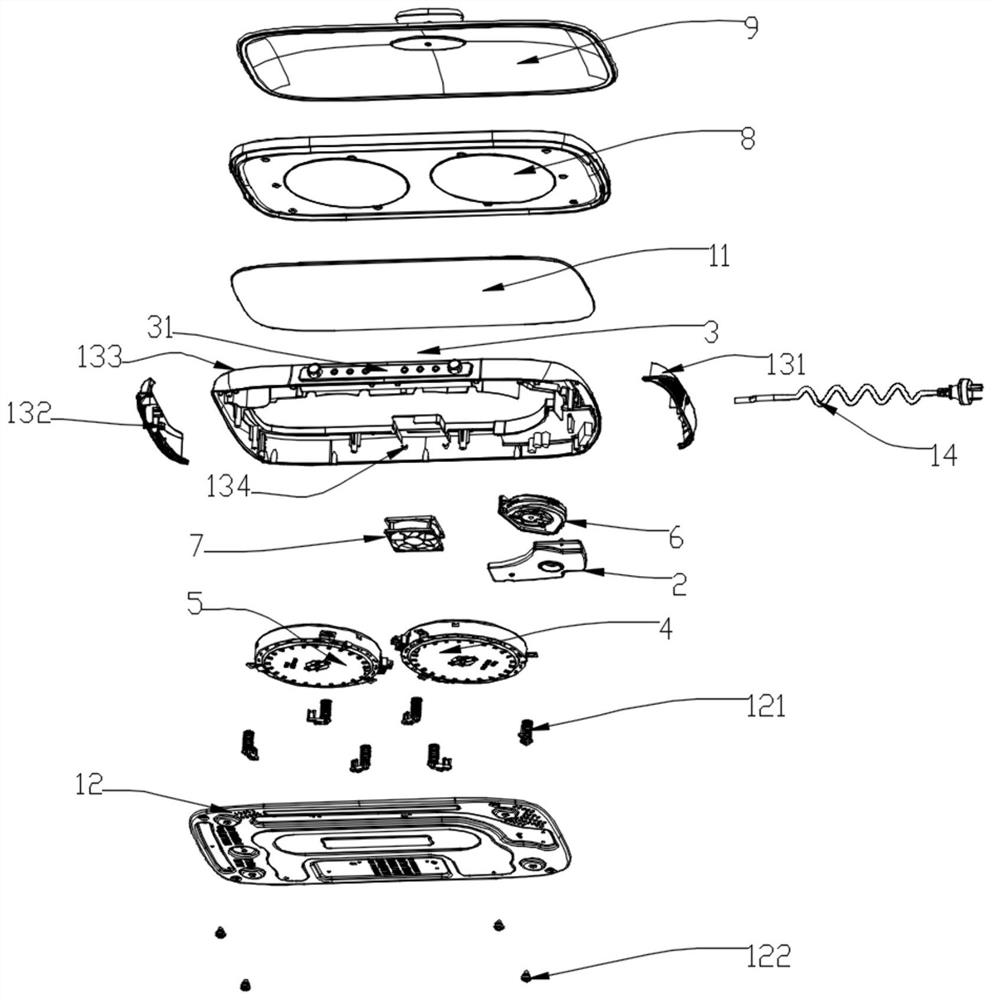

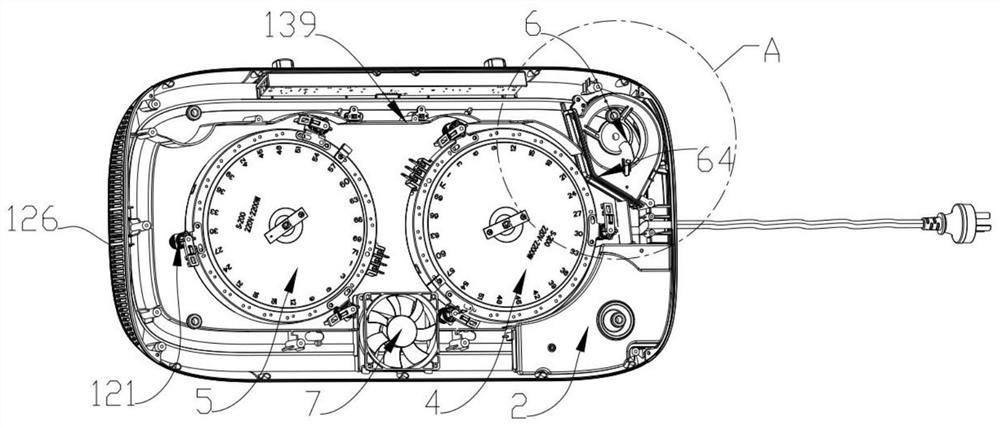

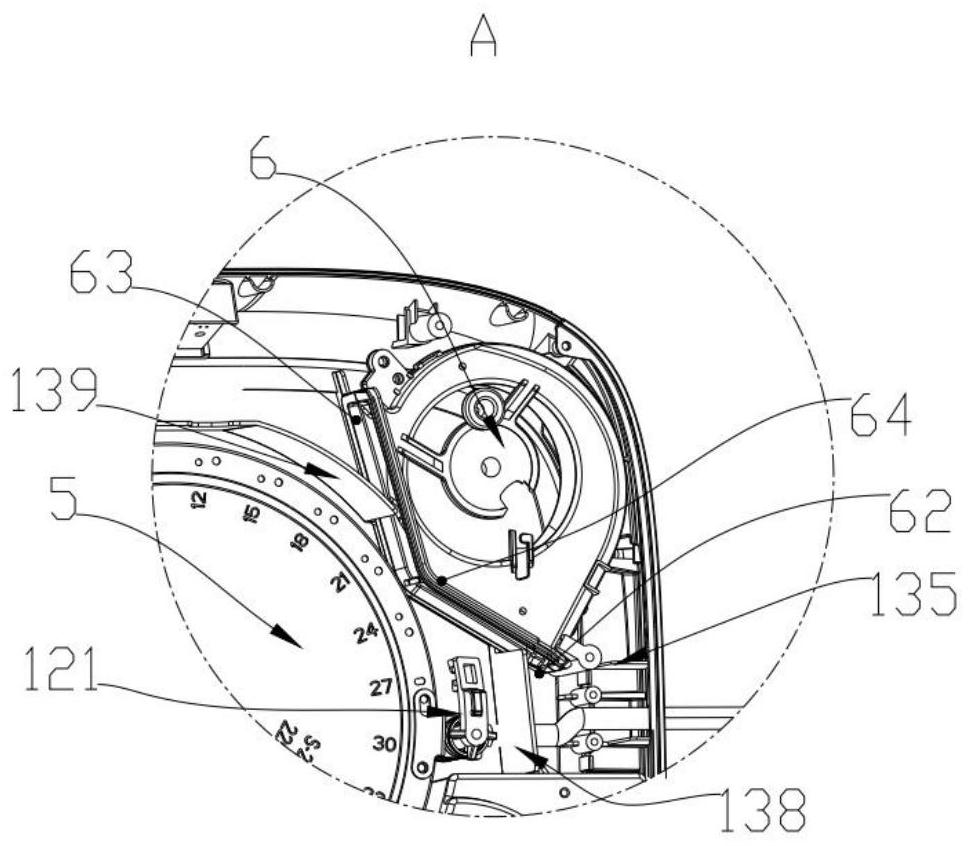

Embodiment 1

[0040] see Figure 1 to Figure 10As shown, the present invention provides a heating cooker, which includes a housing 1, a power board 2, a control board 3, a first heating device 4 and a second heating device 5, wherein the power board 2 is configured to provide heating to the first heating device 4, The second heating device 5 supplies high-frequency current, wherein the control board 3 is configured to receive user's operation instructions and generate operation signals to be sent to the power board 2 . The casing 1 is equipped with a first air duct s1, a second air duct s2, a third air duct s3 and a first fan 6; wherein the first air duct s1 is adapted to direct part of the cooling air discharged from the first fan 6 to The side of the power board 2 guides, and the second air duct s2 is adapted to guide a part of the cooling air discharged from the first fan 6 to the control panel 3 side; the third air duct s3 is adapted to guide part of the cooling air discharged from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com