Integrated parallel heat dissipation device with single air outlet

A technology of a heat dissipation device and an air outlet is applied in the field of integrated parallel single air outlet heat dissipation device, which can solve the problems of large vibration, burnt motor bearings, inability to meet the noise limit and vibration limit of the variable frequency high-speed motor, and achieves simple structure, The effect of large air volume and air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

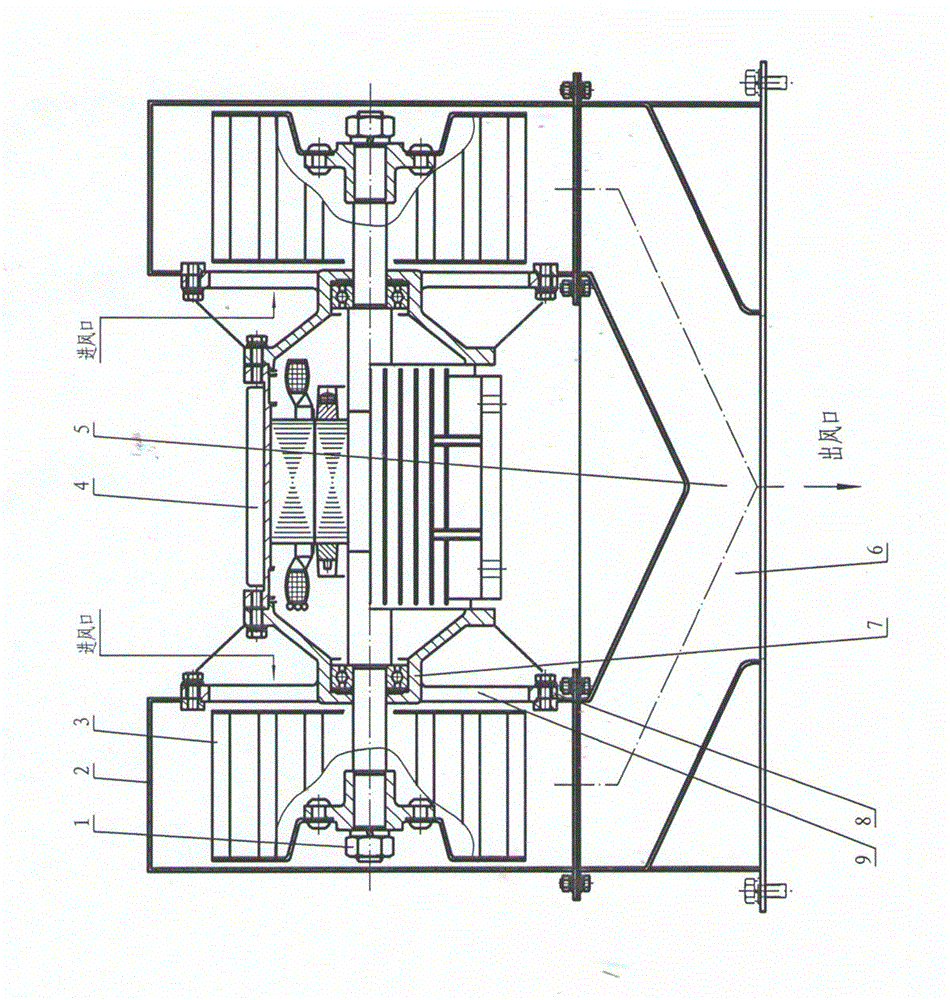

[0014] See figure 1 , including a double-shaft extension motor 4, a volute 2, an impeller 3, and a wind guide base 5. There is a bearing seat 7 in the center of the end cover on both sides of the aforementioned motor 4, and one end of the aforementioned end cover is matched with the base of the motor 4 with a notch. Positioning and bolt connection, the other end is a flange flange 8, and there are air inlets and reinforcing ribs on the radial end surface between the flange flange 8 and the bearing seat 7,

[0015] The aforementioned wind guide base 5 has a Y-shaped air passage 6, the upper end of which is a double air inlet, and the lower end is a single air outlet. The outer spigot of the flange 8 is positioned with the spigot at the other end of the volute 2 and connected with another bolt. The shaft extensions on both sides of the motor 4 are respectively connected with the shaft sleeve of the impeller 3 with a flat key, and locked with a lock nut 1. fasten. The double ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com