Air conditioner shell and air conditioner

An air-conditioning shell and plate technology, which is applied in air-conditioning systems, space heating and ventilation, machines/engines, etc., can solve problems affecting component life, temperature rise, component aging, etc., and keep the heat dissipation channel unblocked. , to ensure the rainproof function, to ensure the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

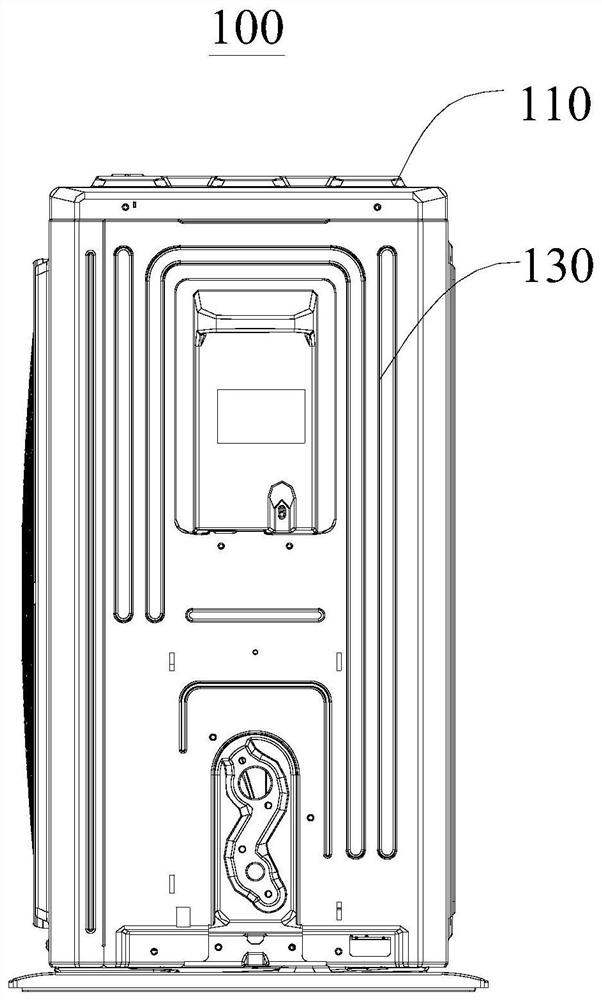

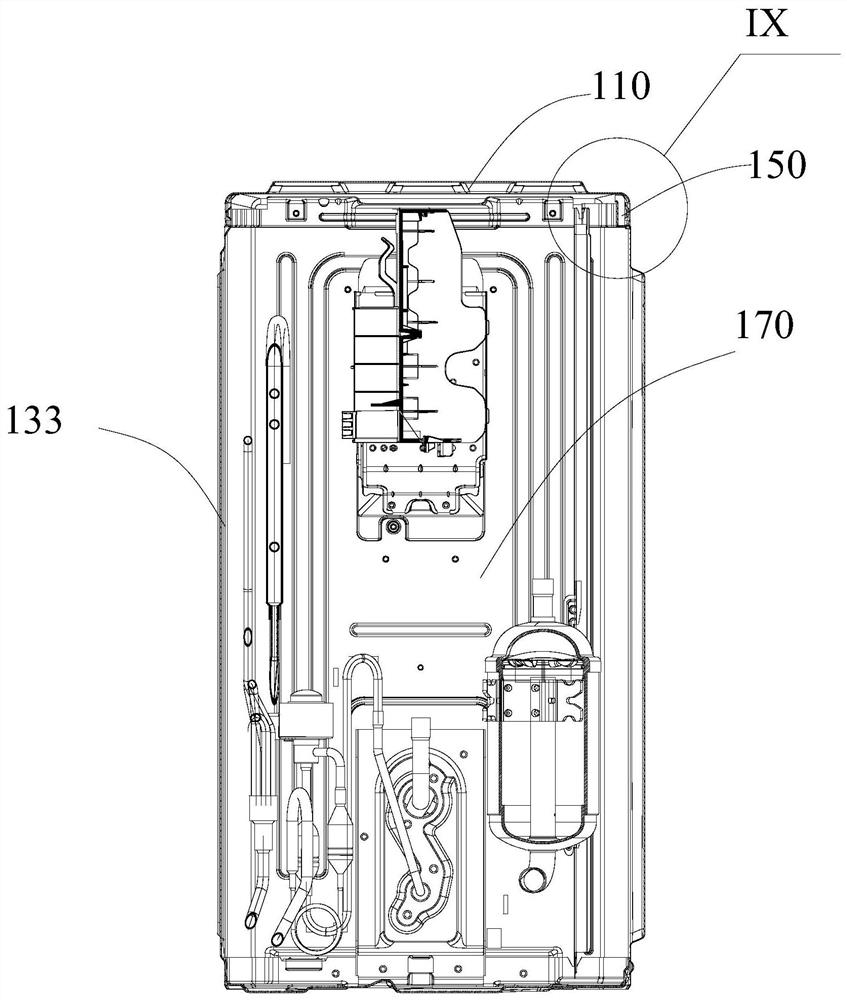

[0046] see Figure 1 to Figure 5 , the present embodiment provides an air conditioner housing 100, which can prevent rainwater from entering the interior of the air conditioner housing 100 through the heat dissipation structure while ensuring heat dissipation by improving the heat dissipation structure.

[0047] The air conditioner casing 100 provided in this embodiment includes a top cover plate 110 and an enclosure 130, the top cover plate 110 is fastened on the top of the enclosure 130, and the top cover plate 110 and the enclosure 130 are formed to accommodate the compressor. 230 inner chamber 170, the outer wall of enclosure 130 is provided with heat dissipation groove 150, the upper part of heat dissipation groove 150 communicates with inner chamber 170, so that the heat of inner chamber 170 is dissipated to the external space through heat dissipation groove 150, and the top cover plate 110 shields the heat dissipation The upper part of the groove 150 is used to prevent ...

no. 2 example

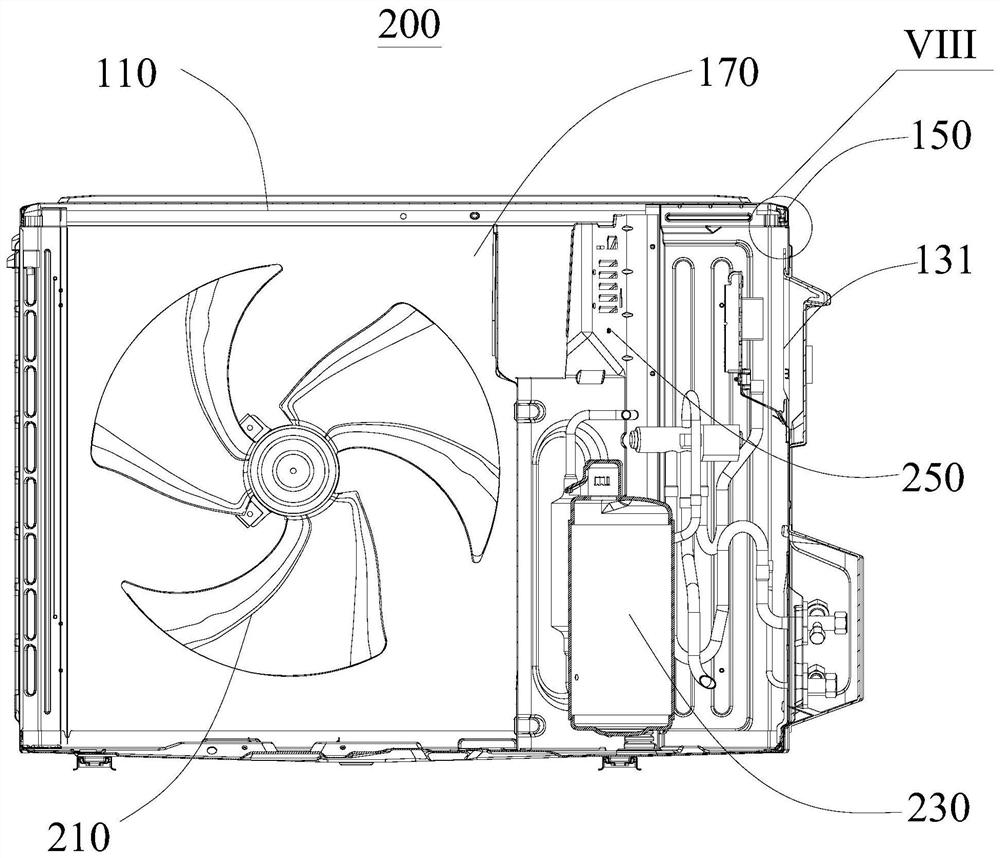

[0072] This embodiment provides an air conditioner 200, including a fan 210, a compressor 230, a controller 250, and an air conditioner housing 100. The basic structure and principle of the air conditioner housing 100 and the technical effects produced are the same as those of the first embodiment, which is For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0073] The air conditioner casing 100 includes a top cover plate 110 and a casing 130, the top cover plate 110 is fastened on the top of the casing 130, and the top cover plate 110 and the casing 130 enclose an inner cavity 170 for accommodating the compressor 230: The outer wall of the enclosure 130 is provided with a cooling groove 150, and the upper part of the cooling groove 150 communicates with the inner cavity 170, so that the heat of the inner cavity 170 is dissipated to the external space through the cooling groove 150, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concave depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com