Double-row tapered roller bearing clearance adjusting method

A technology of tapered roller bearings and adjustment methods, which is applied in the direction of mechanical clearance measurement, etc., can solve the problems of low efficiency, difficulty in mastering, and high efficiency of empirical methods, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the adjustment method of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

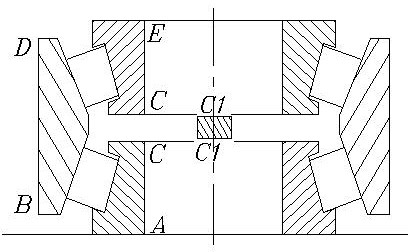

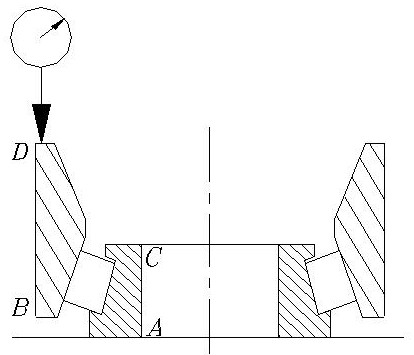

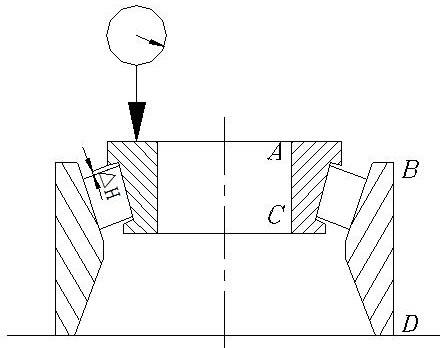

[0028] See attached Figure 1-4 , because the tapered roller will produce a "self-locking phenomenon" between the inner and outer tapered raceways of the bearing, this "self-locking phenomenon" is reflected in image 3 position, there is a gap △H1 that is difficult to eliminate between the large end face of the roller and the thrust rib of the inner ring. We usually think that the gap value △H1 is equal to the sinkage △H. figure 2 Then there will be no "self-locking phenomenon" in the position, and △H will not exist. The present invention is based on a new method of clearance adjustment derived from the generation of △H—the sinking method.

[0029] It should be noted that △H1 is the gap between the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com