Online detection method and system for winnowing stem-picking quality in tobacco primary processing production

A technology of winnowing, stemming and detection system, which is applied in the fields of tobacco, tobacco preparation, and measuring devices, which can solve the problems of increased workload, no accurate component composition data, and unknown tobacco content, so as to reduce the dependence on operators, The effect of reducing the lightness of labor and improving the degree of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

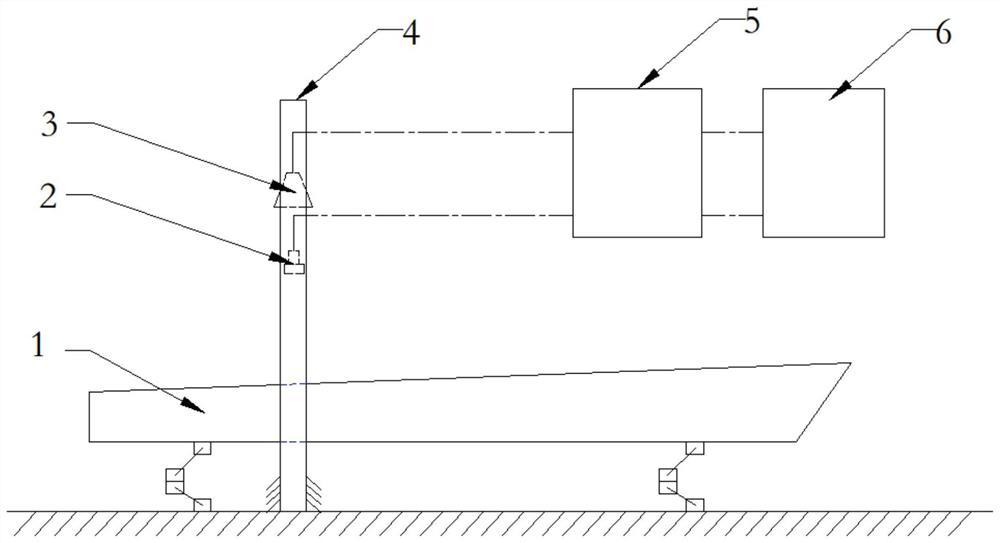

[0020] Such as figure 1 , Tobacco shredded air selection and stalk quality online inspection system includes material thinning machine 1, camera 2, light source 3, mounting bracket 4, electrical control box 5, processor 6.

[0021] The material thinning machine 1 is used for thinning the mixture of stems and shredded tobacco to a certain extent. The camera 2 and the light source 3 are fixed on the mounting bracket 4, the camera 3 is used to capture images, and the light source 3 is used to ensure the light intensity required for image quality. The electrical control device 5 is used for logical control such as starting and stopping of the material thinning machine 1 with the material entering, camera 2 taking pictures or recording, and light source 3 turning on or off. The processor 6 processes the image information, calculates and outputs the weight ratio of the stem stick and shredded tobacco.

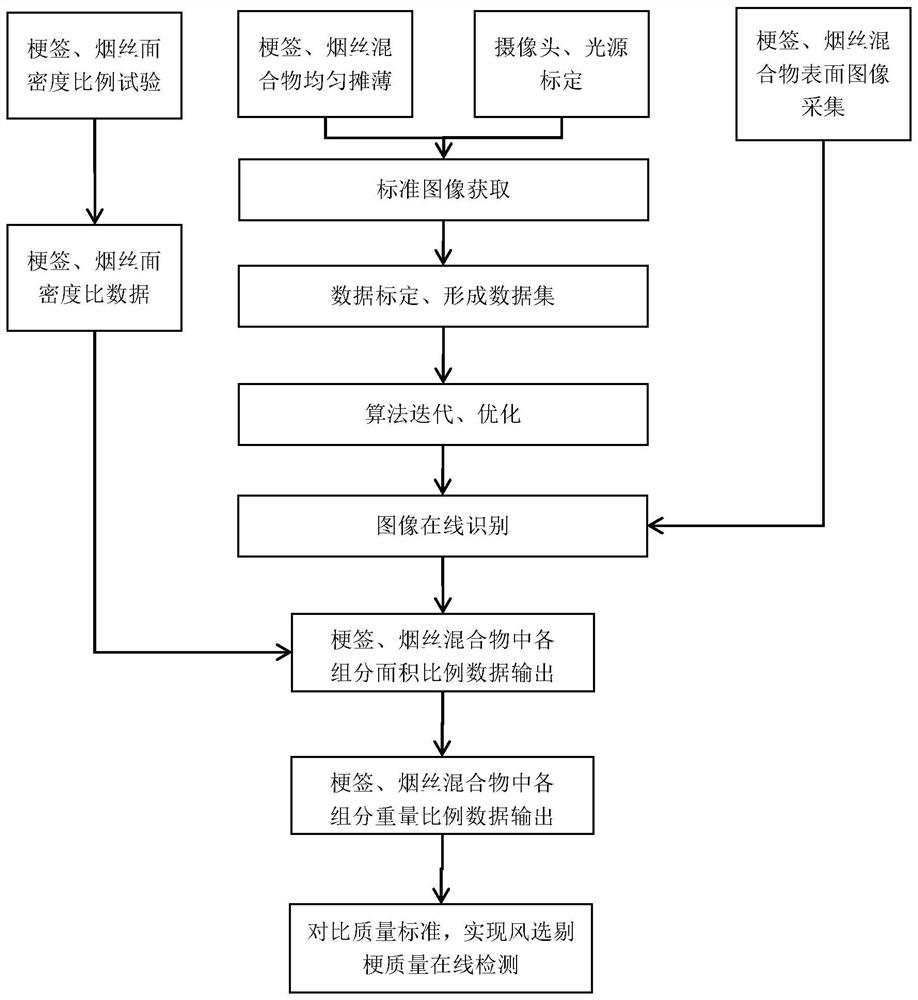

[0022] Combine below figure 2 Explain the detection principle of the system:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com