Cigarette making machine forming constant-temperature equipment

A technology of constant temperature equipment and cigarette making machines, which is applied in the fields of tobacco, temperature control, and cigarette manufacturing, and can solve problems such as difficult cleaning, easy accumulation of dust, and affecting cooling efficiency of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

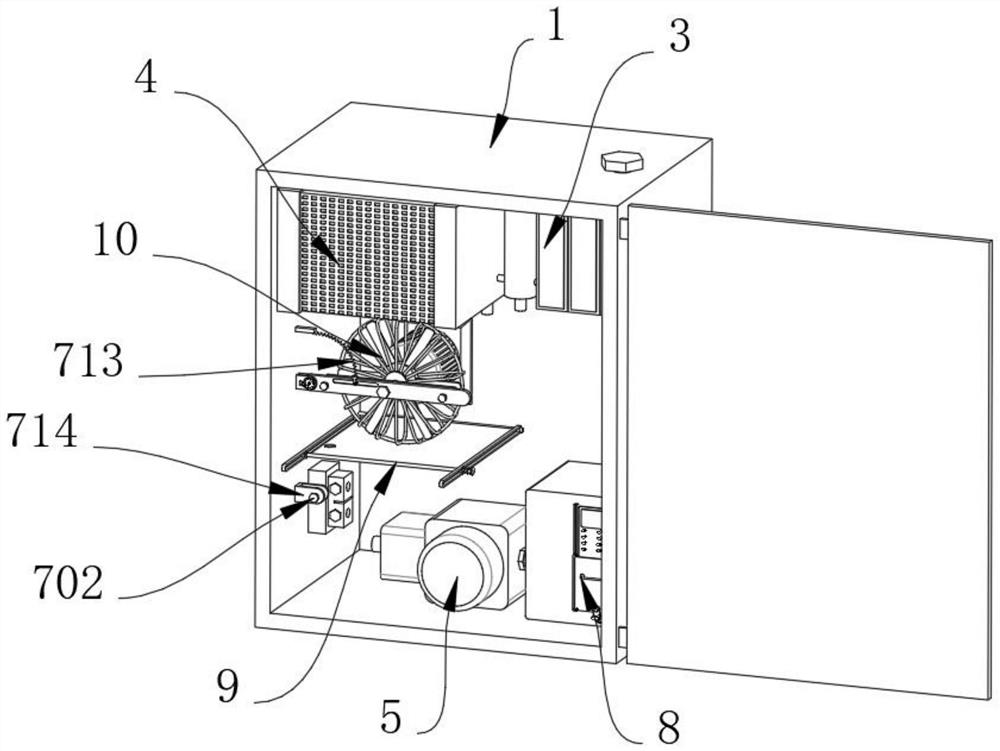

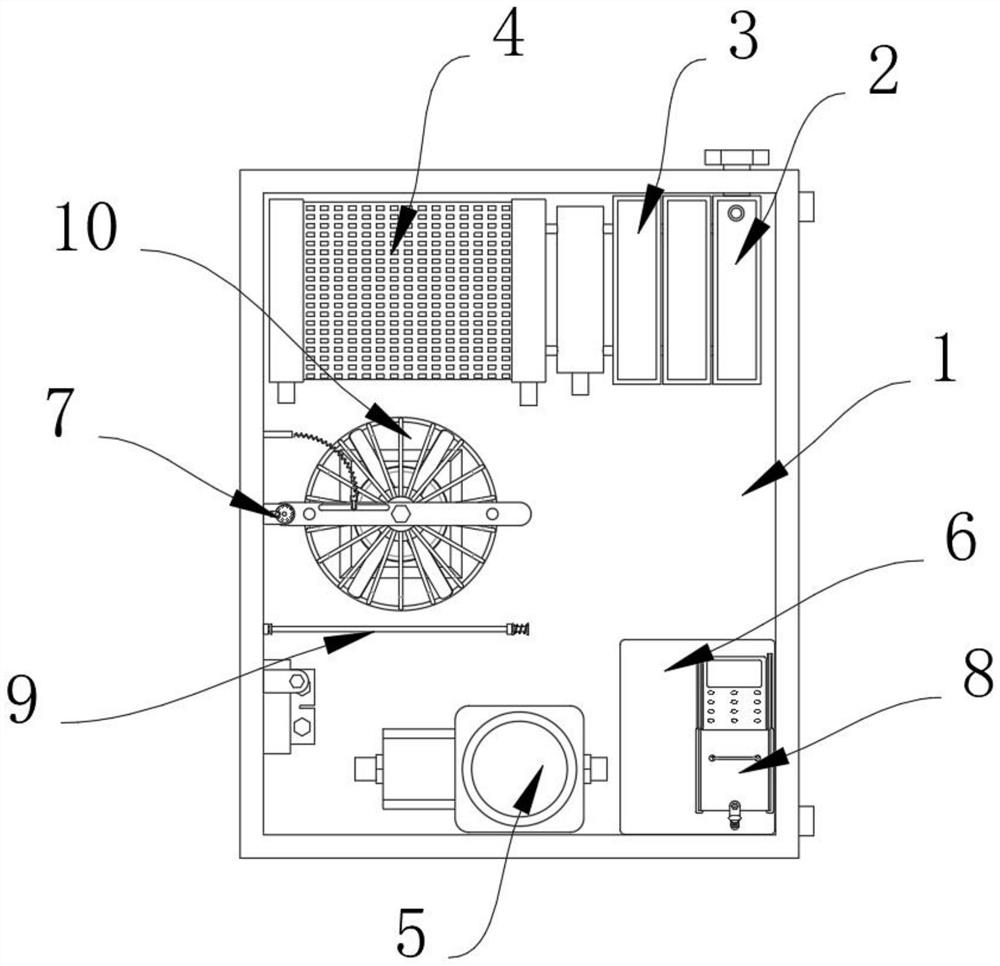

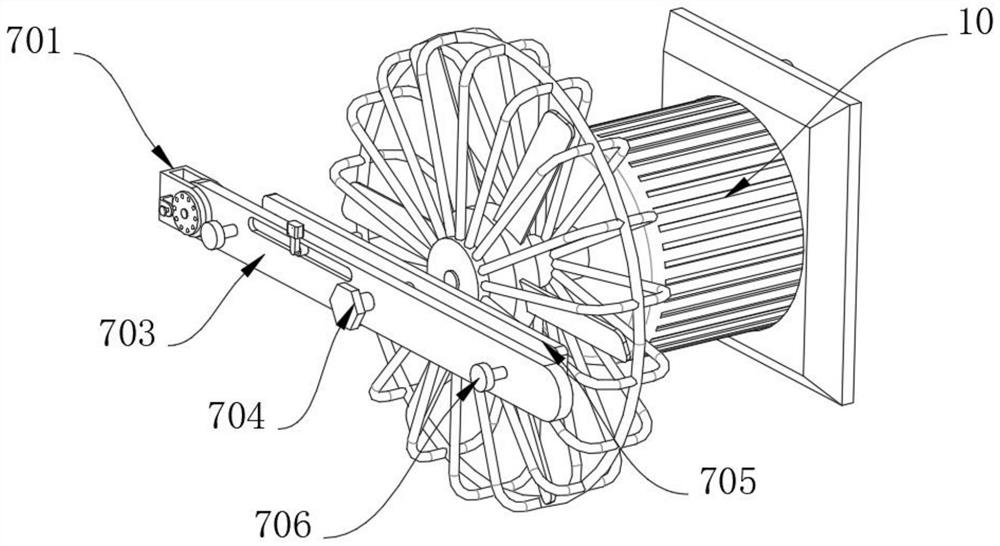

[0031] Example 1, such as Figure 1-8As shown, the present invention provides a cigarette machine forming constant temperature equipment, including a casing 1, a cooling block 2 is installed inside the casing 1, two cooling blocks 3 are installed on one side of the cooling block 2, and the cooling blocks 3 are far away from the cooling A radiator 4 is installed on one side of the block 2, a pump body 5 is installed inside the casing 1, a control electrical box 6 is installed inside the casing 1, a fan 10 is installed on the rear inner wall of the casing 1, and a fan 10 is installed on the inner wall of the casing 1. The inner wall is provided with a cleaning structure 7 , the surface of the control electrical box 6 is provided with a protective structure 8 , and the inner wall of the casing 1 is provided with a collecting structure 9 .

[0032] Let's talk about the specific settings and effects of its cleaning structure 7, protective structure 8 and collection structure 9 belo...

Embodiment 2

[0039] Embodiment 2, on the basis of Embodiment 1, the collection structure 9 includes a rotating shaft 91, the rotating shaft 91 is rotatably connected to the inner wall of the casing 1, the arc surface of the rotating shaft 91 is fixedly connected with a collecting cloth 92, and the surface of the collecting cloth 92 is provided with A hole 96 is reserved, and the end of the collecting cloth 92 away from the rotating shaft 91 is fixedly connected with a fixed rod 93, and one end of the fixed rod 93 is fixedly connected with a limit block 94, and the arc surface of the limit block 94 is slidably connected with a limit rail 95, and the limit rail 95 is fixedly connected to the inner wall of the casing 1, and the arc surface of the fixed rod 93 is slidably connected with a fixed rail 97, and one end of the fixed rail 97 is fixedly connected with the casing 1, so that when the cleaning structure 7 is used to clean the blower fan 10, The effect of collecting the dust under the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com