Multi-efficient heat dissipation system for battery of electric automobile

A technology for electric vehicles and heat dissipation systems, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as limited space for battery installation, impact on performance and service life, and rise in temperature at the location of the battery, so as to improve the heat dissipation effect and volume Small, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

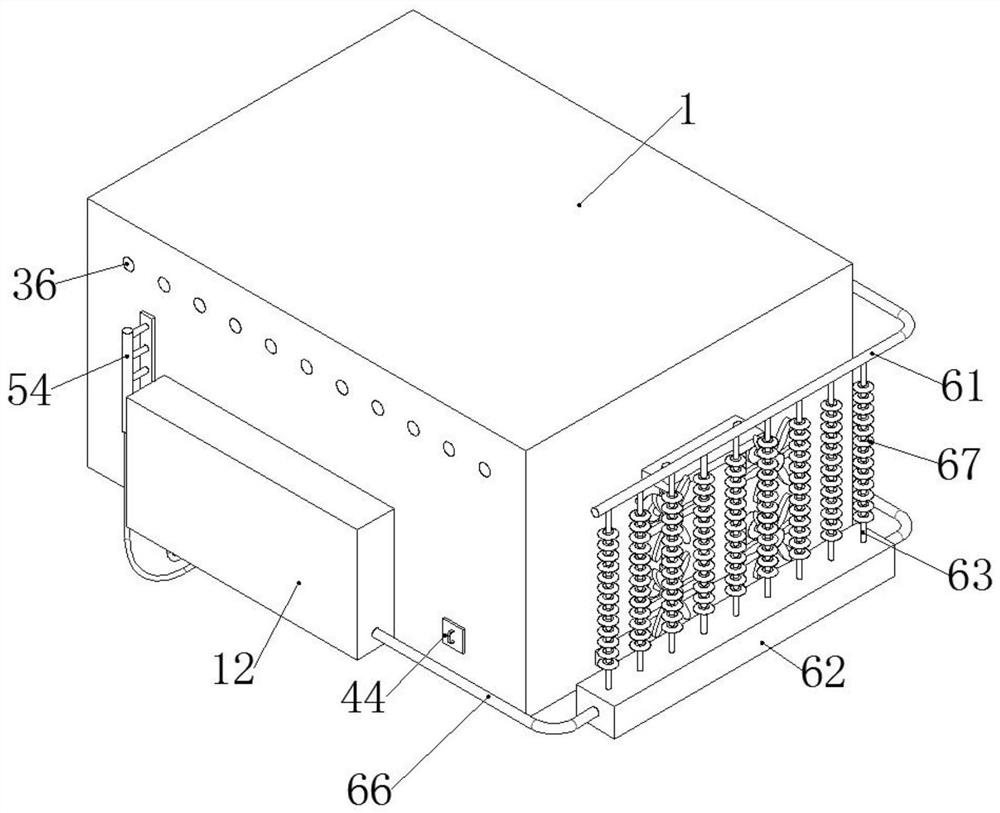

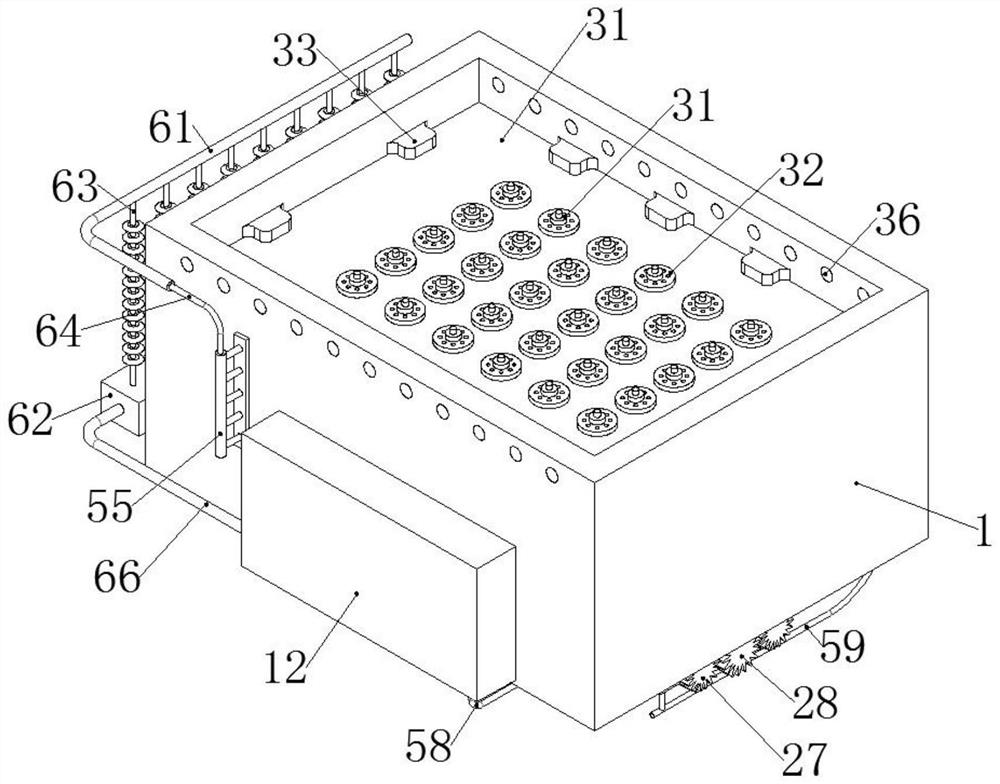

[0048] A multiple high-efficiency heat dissipation system for batteries of electric vehicles, including an installation case 1 and a battery cell 11 arranged in the installation case 1, the outer walls of the front and rear side panels of the installation case 1 are symmetrically fixed with a cooling box 12, and also includes a pump Sending device, air cooling device, filter device 4, liquid cooling device and cooling device;

[0049] The pumping device is located at the bottom of the installation shell 1;

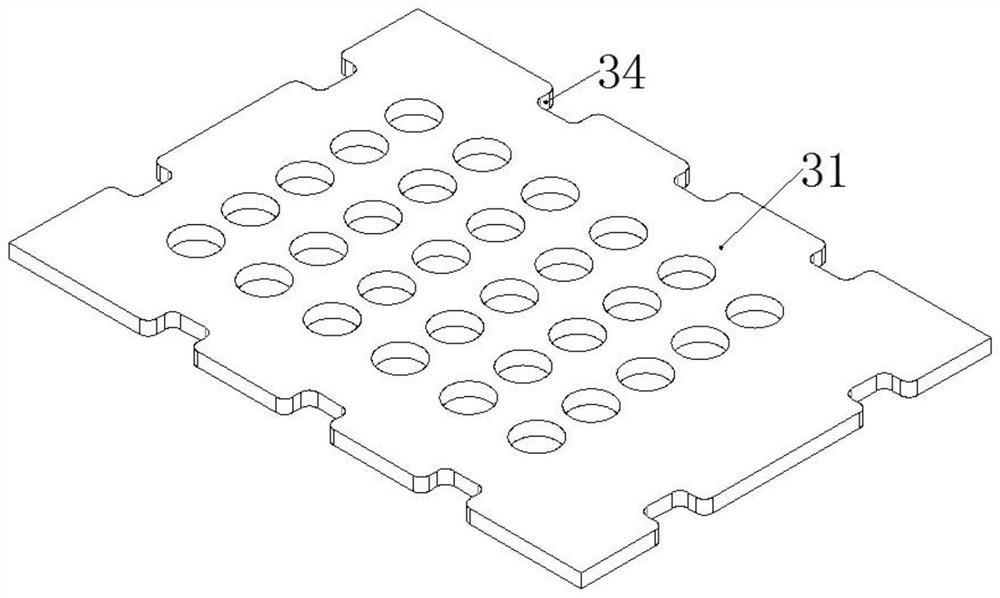

[0050] The air-cooling device includes a bracket 31 and a cooling fan 32; the bracket 31 is fixedly connected in the installation housing 1 and a pair is arranged at intervals up and down, the inner wall of the installation housing 1 is fixedly connected with a welding seat 33, and the bracket 31 is provided with The notch 34 corresponding to the welding seat 33, the notch 34 and the welding seat 33 are fixed by welding, the cooling fan 32 is fixed between the brackets 31,...

Embodiment 2

[0061] On the basis of Embodiment 1, this embodiment discloses the following specific structure of the pumping device:

[0062] The pumping device includes a pump chamber 21, a reciprocating screw rod 22, a piston 23 and a motor 24; the pump chamber 21 is fixedly connected to the bottom of the installation housing 1 and arranged symmetrically front and back, and the reciprocating screw rod 22 passes through the first shaft rod 25 and the The second shaft rod 26 is rotatably connected in the pump chamber 21, the head of each first shaft rod 25 stretches out of the pump chamber 21 and is fixedly connected with a driven gear 27, and the piston 23 is sealingly and slidingly connected in the pump chamber 21 and The reciprocating screw mandrel 22 meshes, and the motor 24 is fixedly connected between the pump chambers 21. The output shaft head of the motor 24 is fixedly connected with a driving gear 28, and two driven gears 27 mesh with it at the front and rear sides of the driving ge...

Embodiment 3

[0067] On the basis of Embodiment 2, this embodiment discloses the connection structure between the air cooling device and the pump chamber 21, and specifically discloses the following technical features:

[0068] The right side of each pump chamber 21 is fixedly connected with a one-way air inlet pipe 37, and the right side of the bottom plate of each pump chamber 21 is fixedly connected with a one-way air outlet pipe 38. The direction that the one-way air outlet pipe 38 allows gas to pass is the direction away from the inner cavity of the pump chamber 21, and the one-way air inlet pipe 37 and the one-way air outlet pipe 38 realize the one-way conduction ability through the one-way air valve provided therein, forming The bottom of a group of heat dissipation air cylinders 32 in the row is connected with a first pipe 39, the right end of each first pipe 39 is connected with the filter device 4, and the filter device 4 is also connected with a second pipe 310, and the second pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com