Partition plate for battery module, battery module, battery pack and electric vehicle

A technology of battery module and battery pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

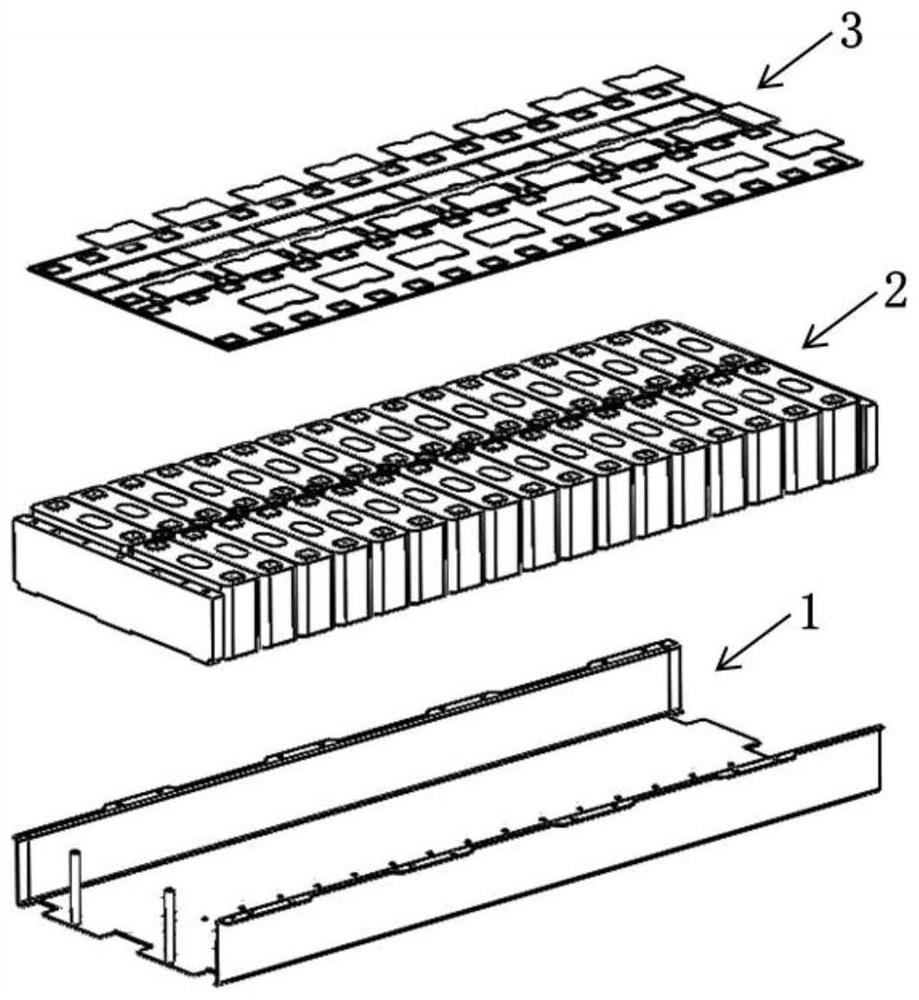

[0081] This embodiment provides a battery pack, including a battery module and a box sheathed on the outer wall of the battery module, wherein the battery module includes a fixed bottom plate 1, a cell module 2 and a connection assembly 3, and the battery module is located on a fixed In the bottom plate 1, a connection assembly 3 is provided on the side of the battery module away from the fixed bottom plate 1.

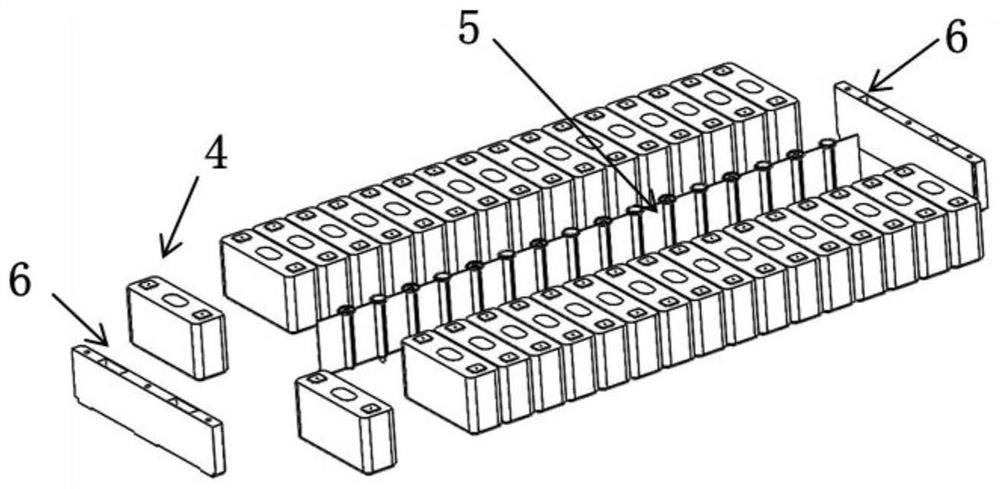

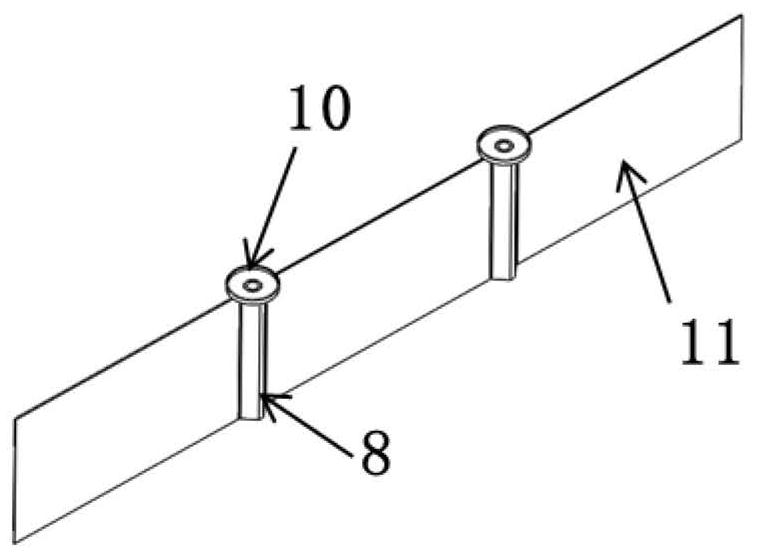

[0082] Both sides of the cell module 2 are respectively provided with end plates 6, such as Figure 5 As shown, the cell module 2 includes two sets of cells 4 arranged side by side, seventeen cells 4 are arranged in each group of cells 4, and a separator 5 is arranged between the two groups of cells 4, and the separator 5 Perpendicular to the end plate 6 , the separator 5 includes seventeen barrier pieces 11 , and a pressure bearing member is arranged between two adjacent barrier pieces 11 . The pressure bearing member includes a body 8 and an insulating layer 9 arrang...

Embodiment 2

[0086] This embodiment provides a battery pack, including a battery module and a box sheathed on the outer wall of the battery module, wherein the battery module includes a fixed bottom plate 1, a battery module 2 and a connection assembly 3, and the battery module 2 is located Inside the fixed base plate 1 , and the side of the cell module 2 far away from the fixed base plate 1 is provided with a connection assembly 3 .

[0087] Both sides of the cell module 2 are respectively provided with end plates 6, such as Image 6As shown, the battery cell module 2 includes eleven groups of battery cells 4 arranged side by side, each group of battery cells 4 includes three battery cells 4 connected in sequence, and a separator 5 is arranged between two adjacent groups of battery cells 4 . Ten partitions 5, each partition 5 is parallel to the end plate 6, each partition 5 includes three barrier sheets 11, a pressure bearing is arranged between two adjacent barrier sheets 11, and the pre...

Embodiment 3

[0091] This embodiment provides a battery pack, including a battery module and a box sheathed on the outer wall of the battery module, wherein the battery module 2 includes a fixed bottom plate 1, a battery module 2 and a connection assembly 3, the battery module 2 It is located in the fixed base plate 1 , and the connection assembly 3 is provided on the side of the cell module 2 away from the fixed base plate 1 .

[0092] Both sides of the cell module 2 are provided with end plates 6 respectively. The cell module 2 includes eleven groups of cells 4 arranged side by side. Each group of cells 4 includes three cells 4 connected in sequence. The adjacent two groups of cells A partition 5 is arranged between the cores 4, a total of ten partitions 5, each partition 5 is parallel to the end plate 6, and each partition 5 includes three barrier sheets 11, between two adjacent barrier sheets 11 There is a pressure-bearing part between them, and the pressure-bearing part includes a body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com