Cylindrical oil tank structure transformer

A technology for transformers and oil tanks, applied in the field of transformers, can solve the problems of poor sealing between the tank cover and the oil tank, oil leakage, waste, etc., and achieve the effects of improving mechanical connection strength, eliminating assembly errors, and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present application will be described in detail below in conjunction with specific embodiments.

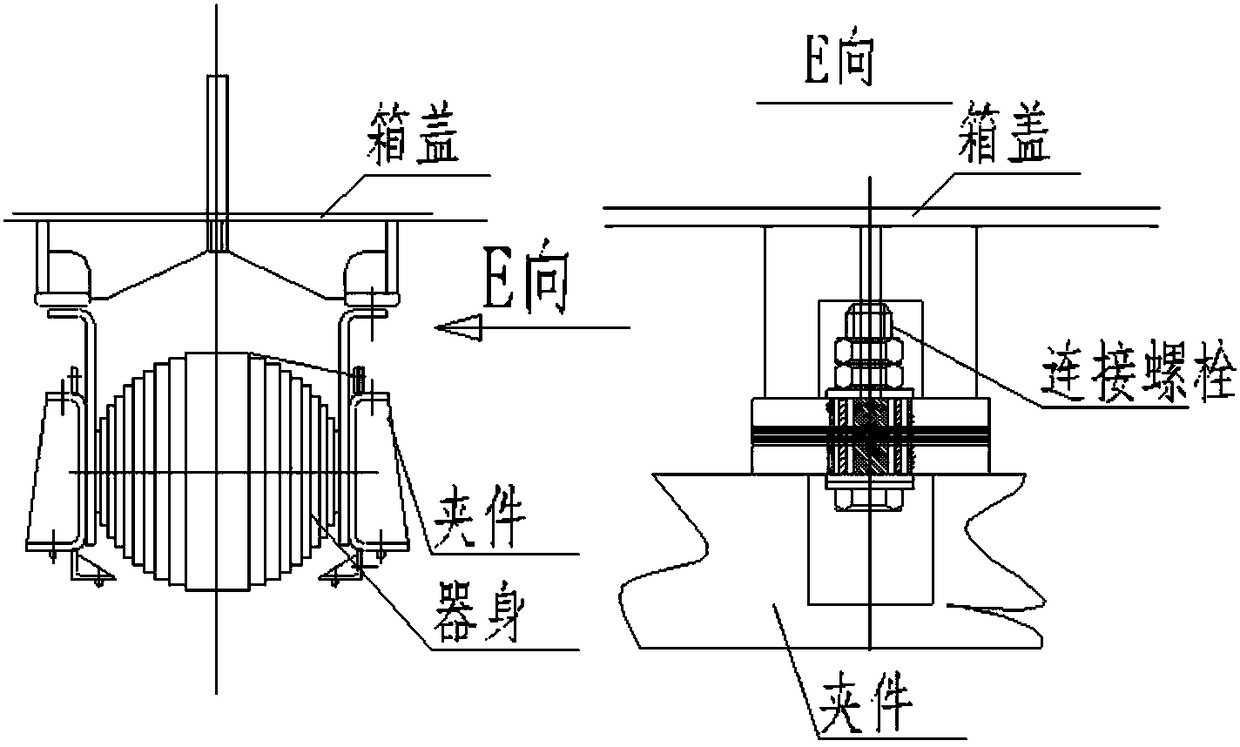

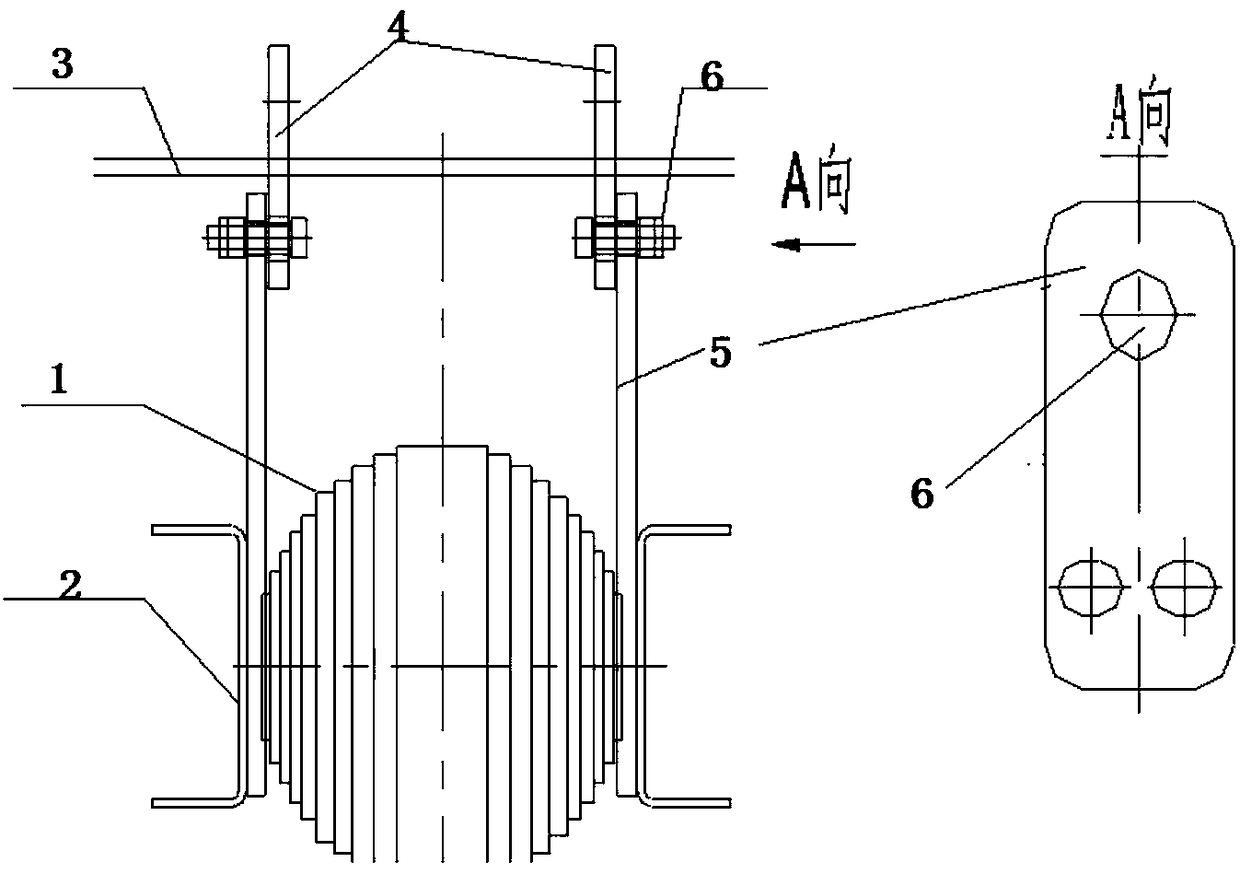

[0018] Such as figure 2 The shown cylindrical oil tank structure transformer includes a body 1, clips 2 placed on both sides of the body 1, and a tank cover 3, the tank cover 3 is provided with a first connecting piece 4 extending downward, so The clamping piece is provided with a second connecting piece 5 extending upwards, and the first connecting piece and the second connecting piece are fixed by transverse connecting bolts 6 . The size of the connecting bolt 6 is generally M16-M24, and the clips 2 on both sides of the device body and the device body 1 are connected and fixed by a pull screw. The connecting bolt 6 is sheathed with an insulating material for insulating the case cover and the clip, specifically a phenolic paper tube. In order to meet the requirements of different sizes of the body, an adjustment support plate can also be added between the first conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com