Solar periodic double-shaft tracking bracket for photovoltaic panel and use method

A dual-axis tracking and periodic technology, applied in the field of solar energy, can solve the problems of complex equipment design, low robustness, and difficult maintenance, and achieve the effect of high degree of automation, meeting maintenance requirements, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

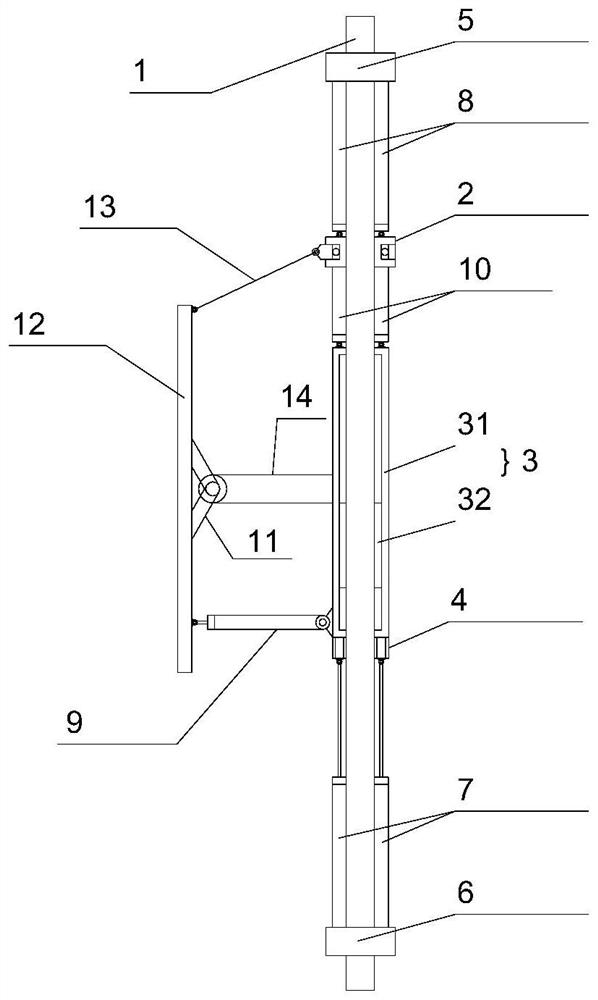

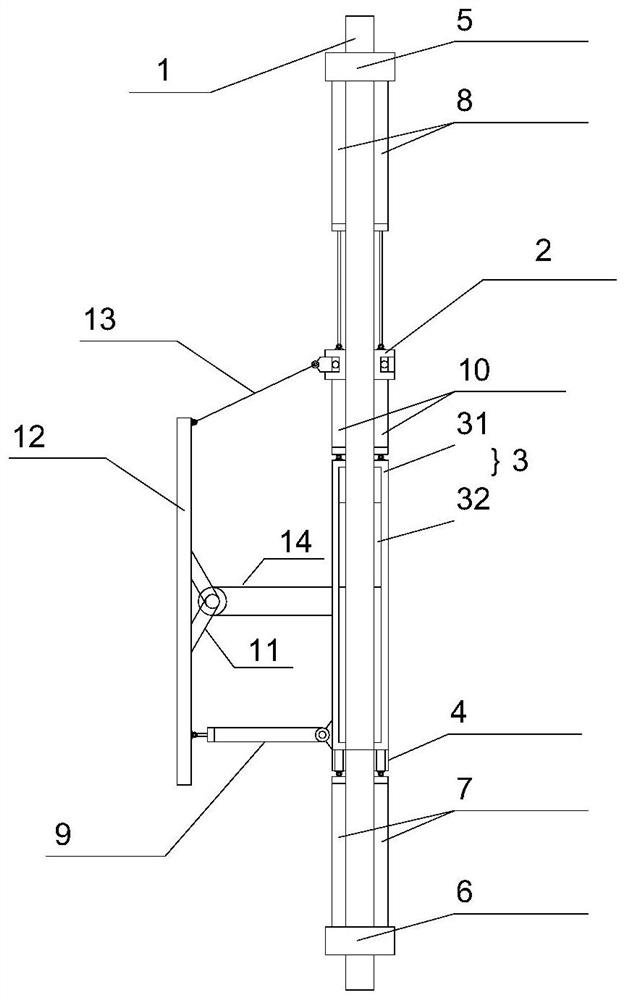

[0028] Combine below Figure 1 to Figure 4 , detailing the structural composition of the sun-directed periodic dual-axis tracking support of the photovoltaic panel of the present invention.

[0029] Please refer to figure 1 , a photovoltaic panel day-to-day periodic dual-axis tracking support, including a pole 1, the two sides of the pole 1 are respectively provided with a sliding top seat 2, a sliding tube set 3 and a push turntable 4, and through the two ends of the pole 1 The fixed top base 5 and the fixed base 6 are fixed, the fixed base 6 is connected with the push turntable 4 through the telescopic oil cylinder 1 7, the sliding top base 2 is connected with the fixed top base 5 through the telescopic oil cylinder 2 8, and the sliding pipe kit 3 is connected with the sliding top base 2 There is a telescopic rod 2 10 between them, the upper end of the photovoltaic panel 12 is connected with the sliding top seat 2 on one side of the vertical rod 1 through a sling 13, and th...

Embodiment 2

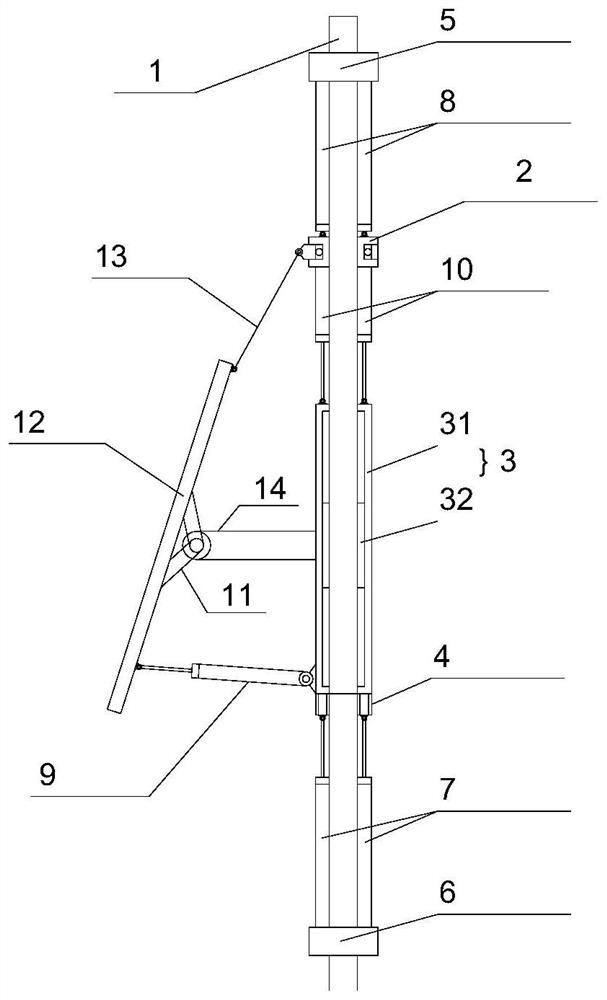

[0032] Please continue to refer Figure 2 to Figure 4 , the present invention also provides a method for using a photovoltaic panel sun-direction periodic biaxial tracking support, the method for using includes the following steps:

[0033] Step S1, providing a photovoltaic panel day-to-day periodic dual-axis tracking bracket for backup;

[0034] Step S2, initial state: the sun is rising, and the photovoltaic panel 12 is facing the east. At this time, the sunlight is incident horizontally and perpendicular to the photovoltaic panel 12;

[0035] Step S3, in the morning: telescopic oil cylinder 1 7 releases pressure, and the inner slide tube 31 with the inner helix will slide down along the outer sleeve 32 with the outer helix under the action of gravity. During the sliding process, fix the inner slide tube The photovoltaic panel 12 on 31 will rotate with the inner sliding tube 31. At the same time, the sling 13 with one end fixed on the sliding top base 2 will pull the photovo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com