Electric propulsion architecture for multi-rotor vertical take-off and landing aircraft and method for controlling such architecture

An electric propulsion, vertical take-off and landing technology, applied in vertical take-off and landing aircraft, aircraft, unmanned aerial vehicles, etc., can solve the problems of increasing the complexity and quality of the electric propulsion system of helicopters or aircraft, and achieve easy detection and isolation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

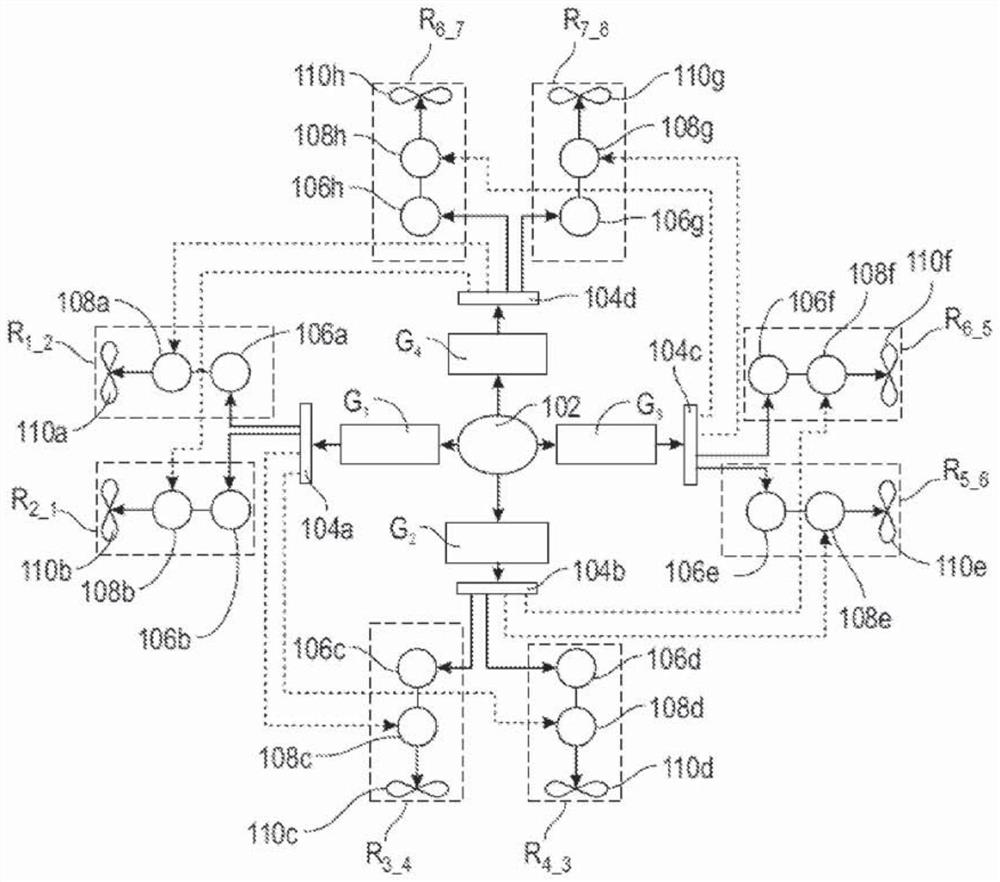

[0070] figure 1 An electric propulsion configuration is shown for a multi-rotor VTOL aircraft and, more precisely, for an octorotor, ie an aircraft with eight lifting rotors.

[0071] The structure includes an electrical energy storage device 102 that supplies power to generators G1-G4, four in this example.

[0072] The generators G1-G4 can be batteries, or fuel cells, or turbine generators.

[0073] Generators G1-G4 are connected to communication buses 104a-d.

[0074] The structure includes R1_2, R2_1, R3_4, R4_3, R5_6, R6_5, R7_8, and R8_7 in this example, for a total of 8 rotors. Each rotor includes two electric motors 106a-h and 108a-h, and propellers 110a-h. The propellers are coupled to the electric motors of the rotors such that during operation, the first electric motors 106a-h drive the propellers.

[0075] The electric motor is connected to a generator such that, during operation, the generator supplies power to the electric motor, in particular via a communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com