Hazardous waste treatment system and hazardous waste treatment process

A treatment system and hazardous waste technology, which is applied in the field of hazardous waste treatment process and hazardous waste treatment system, can solve the problems affecting the incineration effect and the environment, and achieve the effect of improving the incineration effect, reducing the impact, and reducing the amount of water attached

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The application will be described in further detail below in conjunction with the accompanying drawings.

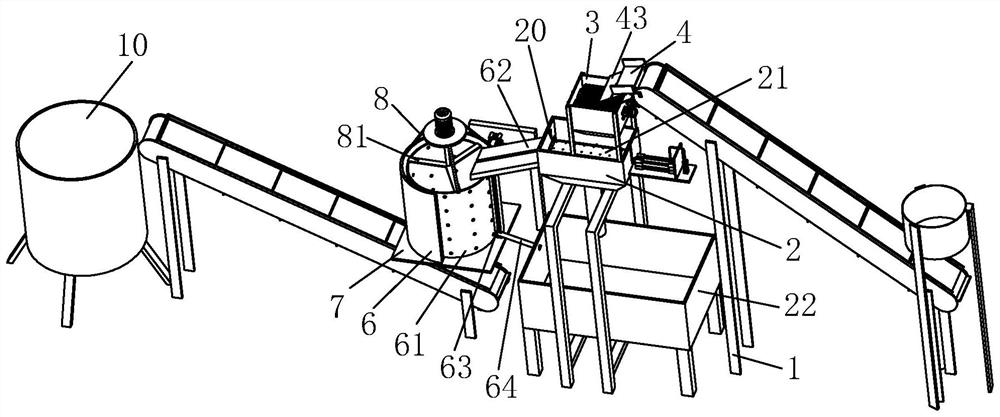

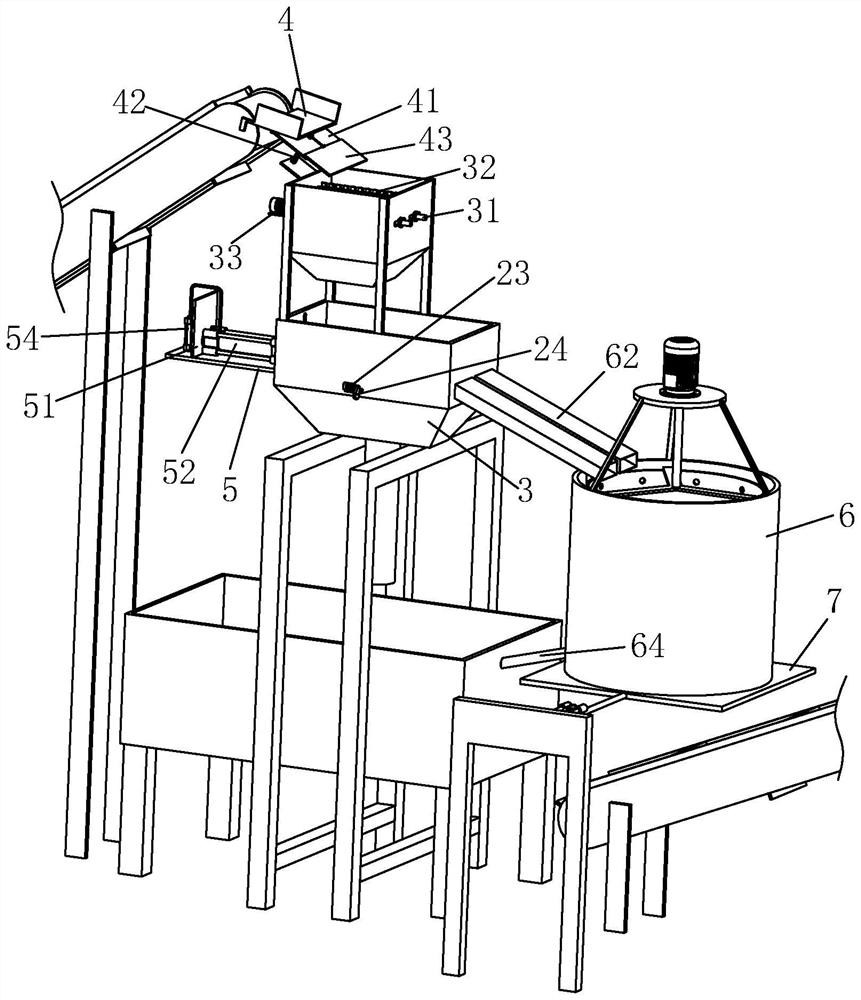

[0038] The embodiment of this application discloses a hazardous waste treatment system, such as figure 1 with figure 2 As shown, it includes: a frame 1, a crushing device is installed on the frame 1, and the crushing device is used for crushing solid waste. At the same time, a first conveying device is also installed on the frame 1, and the first conveying device can replace manual Automatically transport the waste to be crushed to the crushing device for crushing.

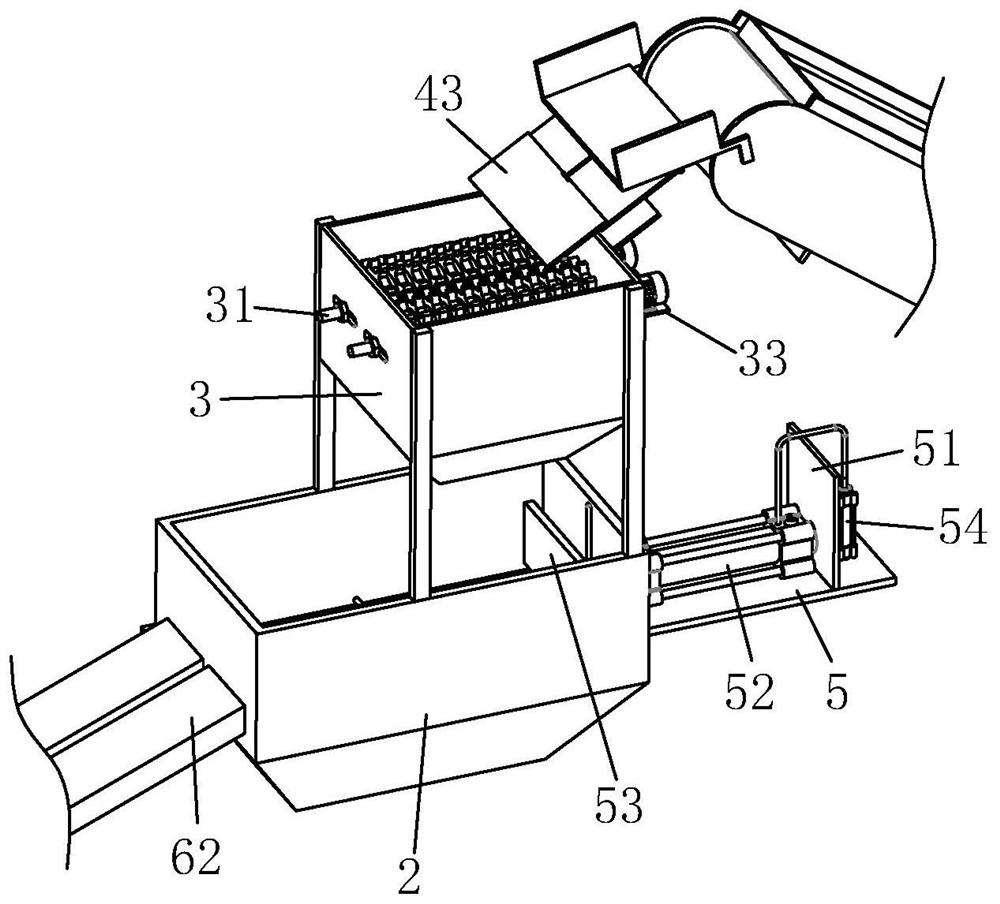

[0039] In this embodiment, the crushing device includes: a crushing bucket 3 installed on the frame 1, the top opening of the crushing bucket 3 is arranged in a rectangular shape, and two rotating rods 31 parallel to each other are installed between the inner walls of the crushing bucket 3. A plurality of crushing blades 32 are installed on the outside of the rod 31 , and at the same time, a driver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com