Open hole well plugging pipe column

A technology for open hole and plugging pipes, applied in wellbore/well components, drill pipe, casing, etc., can solve problems such as complex wellbore, damage to upper oil layer, well kick, etc., to avoid construction risks and reliable anchoring and suspension , the effect of large diameter change range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

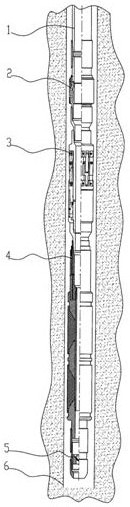

[0026] see figure 1 , figure 2 and image 3 . An open-hole well plugging pipe string includes a delivery pipe string 1, a separation device 2, a suspension support device 3, a plugging device 4, a check valve 5 and an open-hole wellbore 6. The delivery pipe string 1, separation device 2, suspension support device 3, occluder 4 and check valve 5 are connected in sequence and lowered into the open hole wellbore 6.

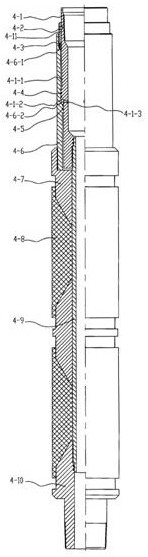

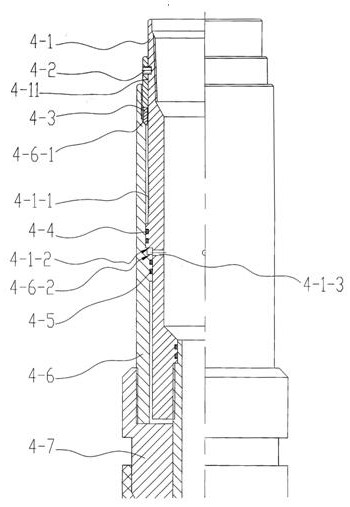

[0027]The occluder includes a sealing inner tube 4-1, a constant pressure shear nail 4-2, a one-way opening lock ring 4-3, an upper sealing ring 4-4, a lower sealing ring 4-5, a sealing outer tube 4-6, Upper cone 4-7, rubber cartridge 4-8, inner pipe 4-9, lower cone 4-10 and connection sleeve 4-11. The outside of the sealed inner tube 4-1 is provided with an outer variable diameter shoulder surface 4-1-2, the outer diameter above the outer variable diameter shoulder surface 4-1-2 is larger than the lower outer diameter, and the sealed inner tube 4-1 1 is provid...

Embodiment 2

[0029] see figure 1 , figure 2 , image 3 and Figure 4 . An open-hole well plugging pipe string includes a delivery pipe string 1, a separation device 2, a suspension support device 3, a plugging device 4, a check valve 5 and an open-hole wellbore 6. The delivery pipe string 1, separation device 2, suspension support device 3, occluder 4 and check valve 5 are connected in sequence and lowered into the open hole wellbore 6.

[0030] The occluder includes a sealing inner tube 4-1, a constant pressure shear nail 4-2, a one-way opening lock ring 4-3, an upper sealing ring 4-4, a lower sealing ring 4-5, a sealing outer tube 4-6, Upper cone 4-7, rubber cartridge 4-8, inner pipe 4-9, lower cone 4-10 and connection sleeve 4-11. The outside of the sealed inner tube 4-1 is provided with an outer variable diameter shoulder surface 4-1-2, the outer diameter above the outer variable diameter shoulder surface 4-1-2 is larger than the lower outer diameter, and the sealed inner tube 4-...

Embodiment 3

[0033] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 . An open-hole well plugging pipe string includes a delivery pipe string 1, a separation device 2, a suspension support device 3, a plugging device 4, a check valve 5 and an open-hole wellbore 6. The delivery pipe string 1, separation device 2, suspension support device 3, occluder 4 and check valve 5 are connected in sequence and lowered into the open hole wellbore 6.

[0034] The occluder includes a sealing inner tube 4-1, a constant pressure shear nail 4-2, a one-way opening lock ring 4-3, an upper sealing ring 4-4, a lower sealing ring 4-5, a sealing outer tube 4-6, Upper cone 4-7, rubber cartridge 4-8, inner pipe 4-9, lower cone 4-10 and connection sleeve 4-11. The outside of the sealed inner tube 4-1 is provided with an outer variable diameter shoulder surface 4-1-2, the outer diameter above the outer variable diameter shoulder surface 4-1-2 is larger than the lower outer diameter, and the sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com