Composite material temporary fastener verification device and use method thereof

A composite material and verification device technology, applied in the field of mechanical assembly, can solve the problems of hole wall, hole edge damage, affecting assembly, excessive clamping force, etc., to achieve the effect of simple verification operation, precise pre-connection, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

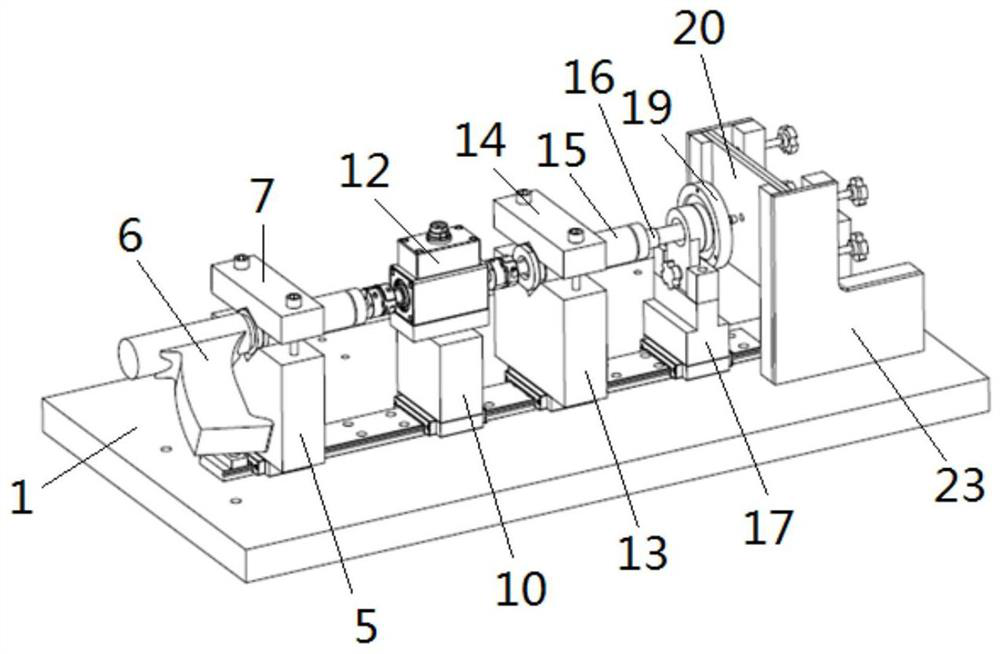

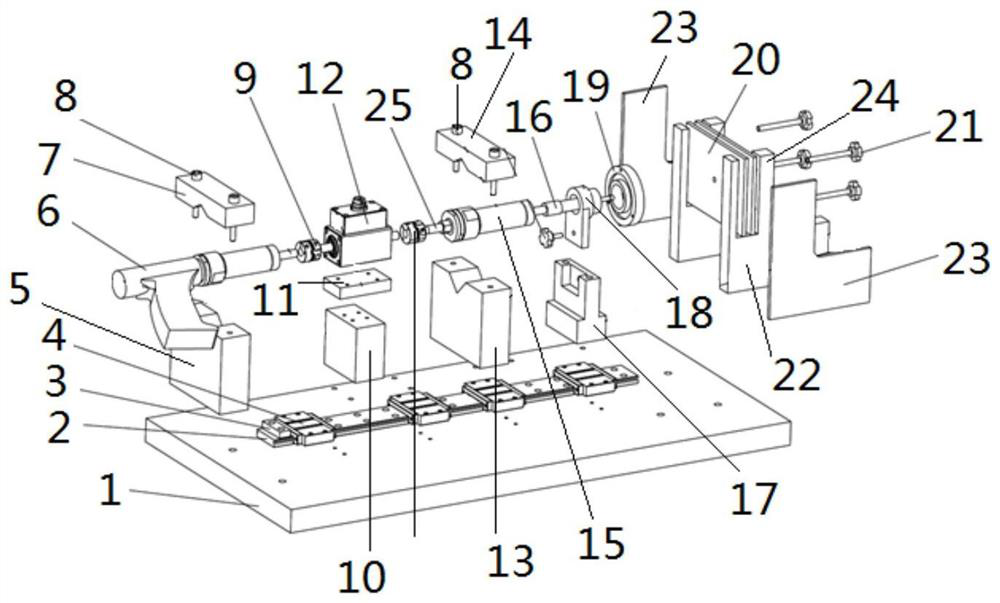

[0049] In this embodiment, a composite material temporary fastener verification device is proposed, which can be used to accurately verify the mapping relationship between the installation process parameters of the air gun 6 and the clamping force generated by the composite material temporary fastener 16, so as to realize Accurate installation of composite temporary fasteners 16.

[0050] Specifically, such as figure 1 and figure 2As shown, the composite material temporary fastener verification device includes a base plate 1 , an air gun 6 capable of sliding on the base plate 1 , a torque sensor 12 , an installer 15 and a pressure sensor 19 . Wherein, the torque sensor 12 can slide on the base plate 1, and the output shaft of the torque sensor 12 and the air gun 6 is connected coaxially by the first coupling 9, and the torque sensor 12 is used to detect the torque of the output shaft of the air gun 6; Can slide on the base plate 1, one end of the installer 15 is connected w...

Embodiment 2

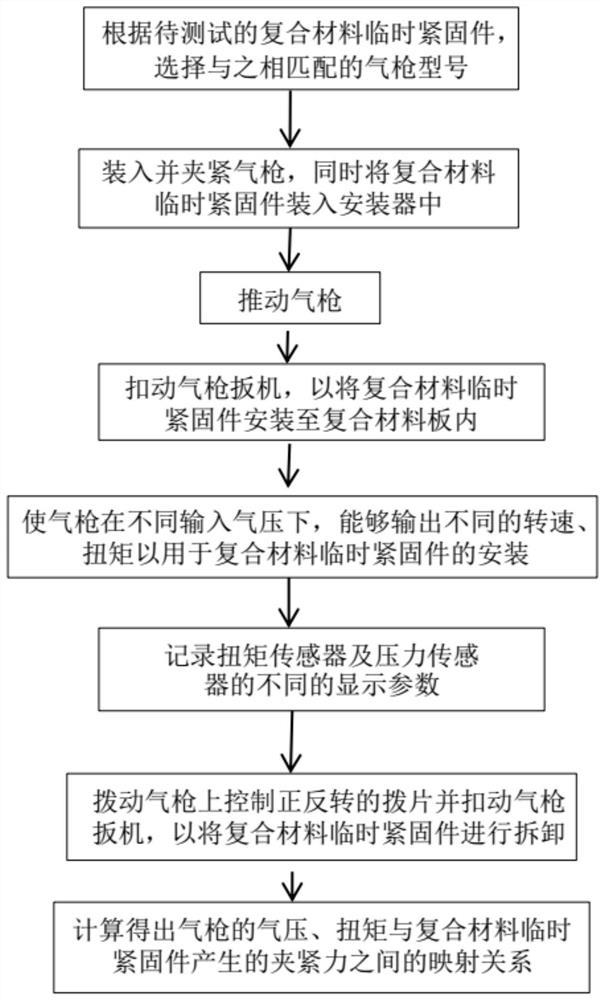

[0059] In this embodiment, a method for using the composite material temporary fastener verification device as in Embodiment 1 is proposed, including the following steps: image 3 As shown, at first, according to the composite material temporary fastener 16 to be tested, select the model of the air gun 6 that matches it, and install the air gun 6 between the first positioning part 5 and the first clamping part 7 to clamp Tighten air gun 6, composite material temporary fastener 16 is packed in the installer 15 simultaneously; Fasteners 16 , composite temporary fasteners 16 , are attached to composite panels 20 .

[0060] Then, after the composite material temporary fastener 16 is tightened on the composite material plate 20, the trigger of the air gun 6 is pulled to promote the composite material temporary fastener 16 to move in a direction close to the composite material plate 20, so that the composite material temporary The fastener 16 is installed in the composite material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com