Full-automatic environment-friendly energy-saving seafood blanching and boiling integrated hot water tank furnace

An environmental protection, energy saving, seafood technology, applied in the direction of fluid heaters, greenhouse gas reduction, lighting and heating equipment, etc., can solve the problems of reducing the heat exchange efficiency of heating pipes, waste of fuel and heat, and high exhaust temperature, so as to avoid land pollution. Waste of resources, reduction of heat loss, and low exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0053] In order to better understand the technical solutions of the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

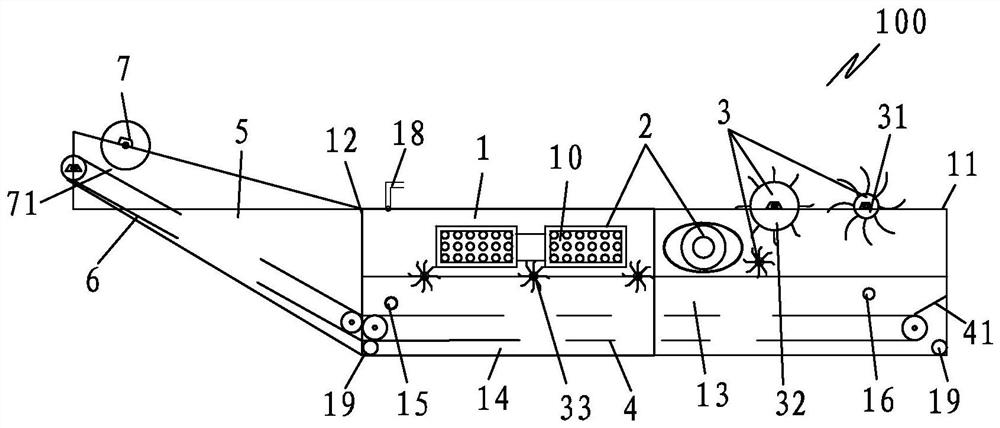

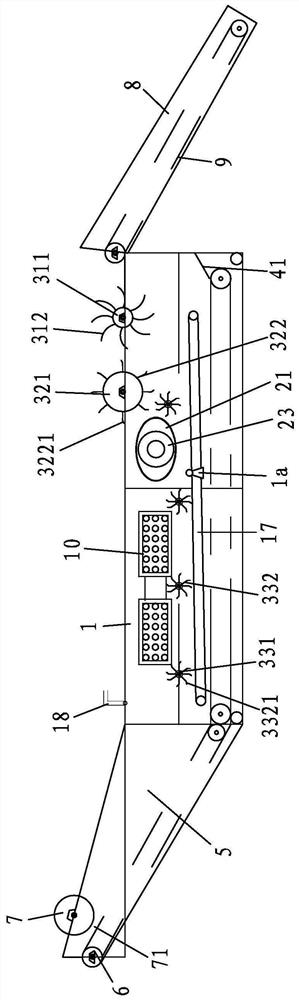

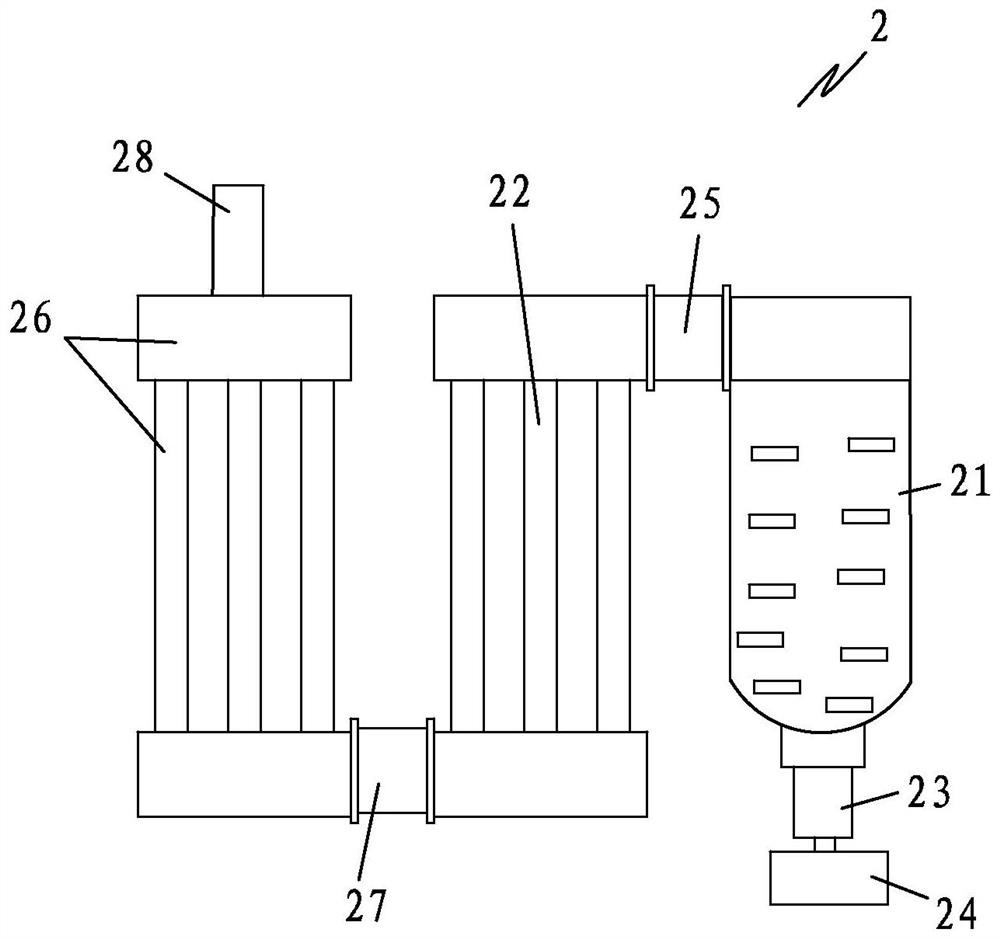

[0054] See Figure 1 to 4 As shown, the present invention has a preferred embodiment of a fully automatic environmental energy-saving seafood, and the hot tank furnace 100 includes a hot boiled water tank 1, which is provided in the hot boiled tank 1. The combustion heating device 2 and a material push mechanism 3 in the hot boiled tank 1; wherein the hot boiled sink 1 is used to accommodate sea products to be hot, such as kelp, sea cucumber, etc .; 2 is used to heat the cold water in the hot boiled tank 1, realize hot boiled function; the material boost mechanism 3 is used to assist the sea product that will be placed in a hot boiled water tank 1.

[0055] The hot boiled water tank 1 has a feed end 11 and a discharge end 12, and the hot boiled sea produc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap