Compression system for wooden door processing

A compression system and wood door technology, applied in wood compression, wood processing appliances, manufacturing tools, etc., can solve the problems of substandard product quality, material waste, poor compression effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

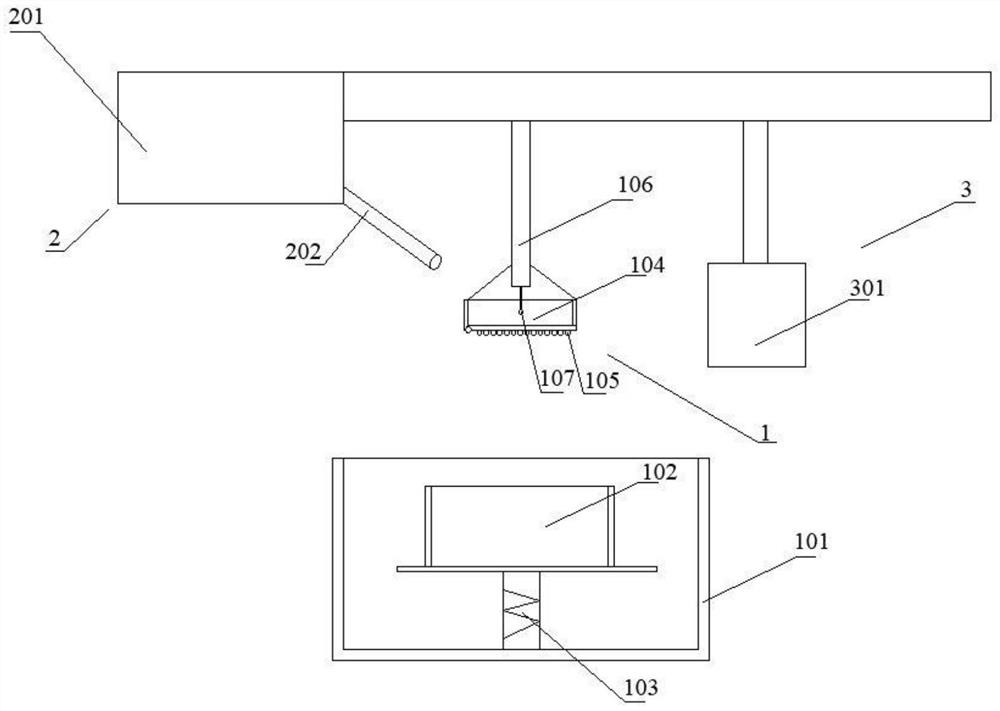

[0025] Please also refer to the attached Figure 1-Figure 2 , the present embodiment provides a compression system for wooden door processing. The compression system for wooden door processing is mainly used to solve the problems of substandard product quality and serious waste of materials caused by poor compression effect in the prior art. This system is already in the stage of actual use.

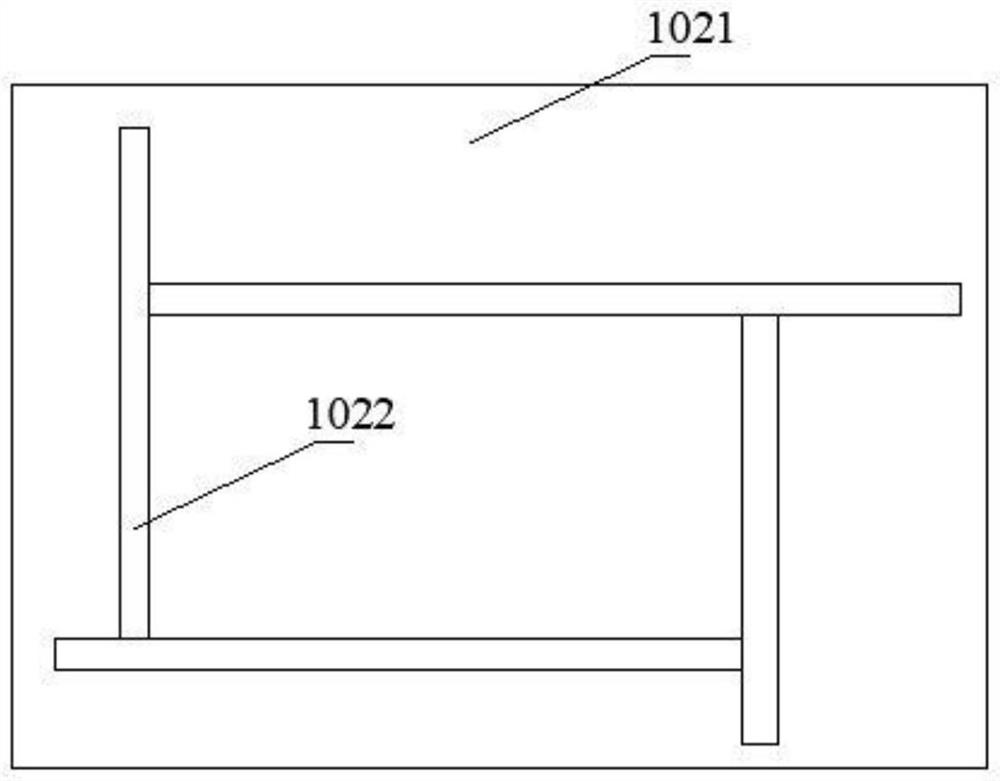

[0026] The specific embodiment of the present invention is as follows, the system includes a finishing assembly 1, a feeding assembly 2 and a pressing assembly 3; the finishing assembly 1 is used to adjust the material to be compressed to a suitable angle; the pressing assembly 3 is used to compress the Material compression molding; the feeding assembly 2 is used to transport the material to be compressed into the finishing assembly 1; wherein, the finishing assembly 1 includes a movably connected forming box 101 and an adjustment mechanism, and the forming box 101 is provided with a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com