Mold and injection molding machine for producing buffer injection molding part

A technology for injection parts and injection molds, applied in the fields of molds and injection molding machines, can solve the problems of missing or falling off of sponges, increasing the labor intensity of production personnel, affecting the assembly quality of line body air conditioners in the assembly workshop, and achieving low processing costs. , The effect of reducing labor intensity and preventing leakage and foolproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

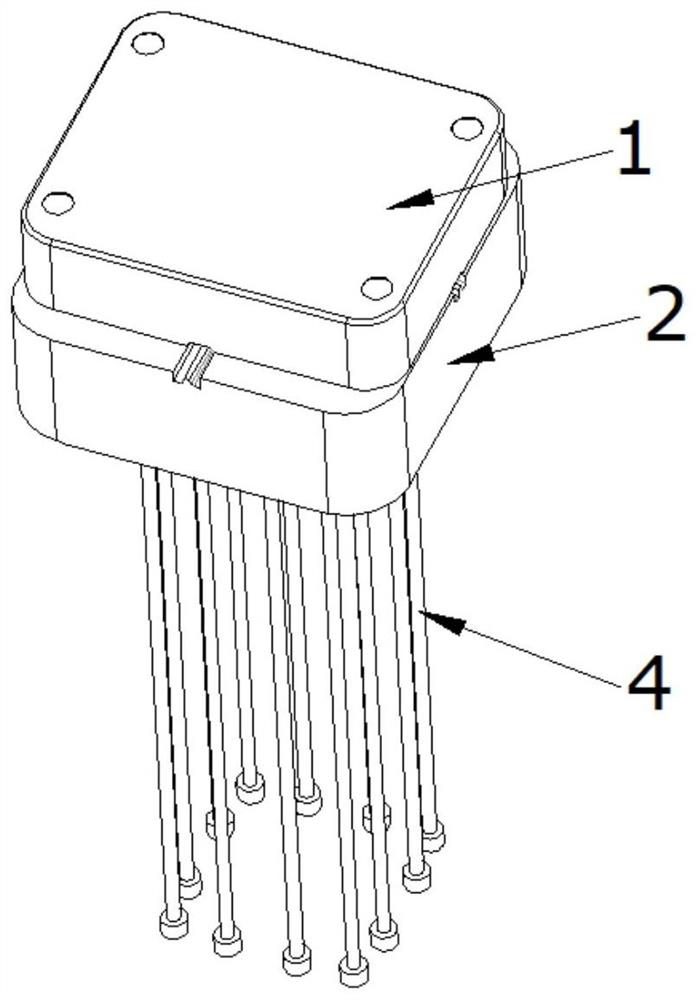

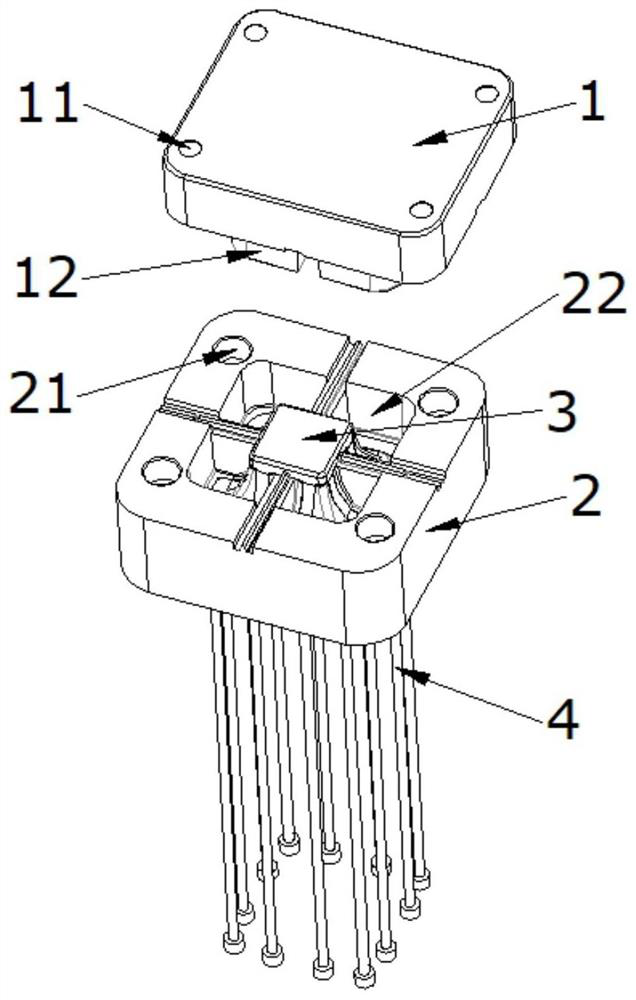

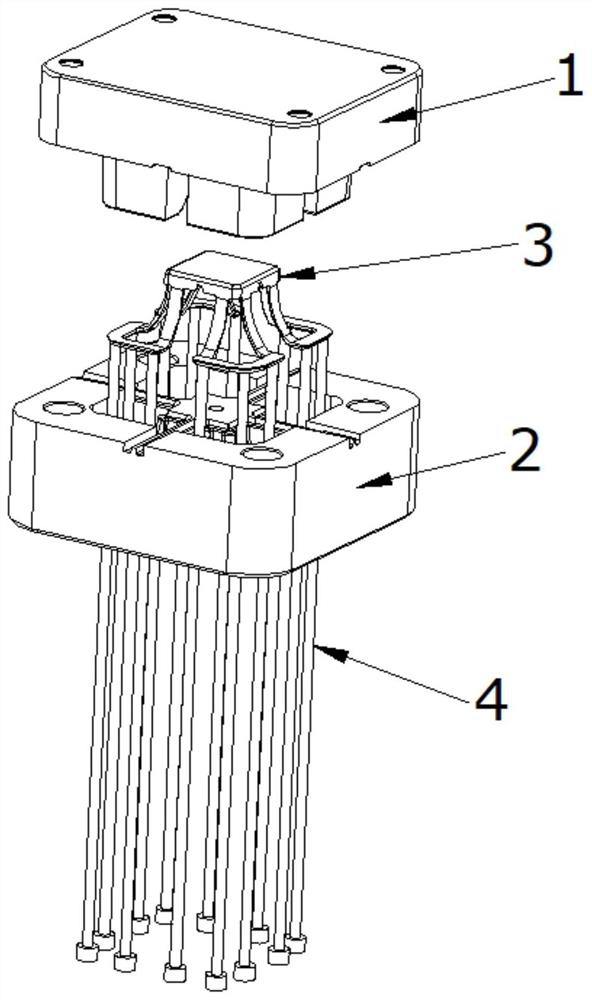

Embodiment example 1

[0062] A mold for producing cushioning injection molded parts, comprising a fixed mold insert and a movable mold insert, the fixed mold insert and the movable mold insert are fixedly connected by a fixture; the fixed mold insert is provided with a bump, The movable mold insert is provided with a groove; the groove includes an accommodating cavity adapted to the bump, and the bump is inserted into the groove to form an injection mold cavity, which is used for injection molding to form a buffer injection model. The buffer injection molded part includes a base plate, one side of the base plate is connected with a buffer claw, and the base plate and the buffer claw are integrally formed by injection molding. There are 4 buffer claws. The buffer claw includes two buffer parts and a support part, the buffer part is arc-shaped, the support part is connected to one end of the buffer part, and the other end of the buffer part is connected to the substrate. By providing the support po...

Embodiment example 2

[0064] A mold for producing cushioning injection molded parts, comprising a fixed mold insert and a movable mold insert, the fixed mold insert and the movable mold insert are fixedly connected by a fixture; the fixed mold insert is provided with a bump, The movable mold insert is provided with a groove; the groove includes an accommodating cavity adapted to the bump, and the bump is inserted into the groove to form an injection mold cavity, which is used for injection molding to form a buffer injection model. The buffer injection molded part includes a base plate, one side of the base plate is connected with a buffer claw, and the base plate and the buffer claw are integrally formed by injection molding. There are at least two buffer claws. The number of buffer claws can be set according to actual needs. The buffer claw includes at least three buffer parts and a support part, the buffer part is arc-shaped, the support part is connected to one end of the buffer part, and the ...

Embodiment example 3

[0066] An injection molding machine for producing buffer injection molded parts, comprising the above-mentioned mold.

[0067] Main function of the present invention:

[0068] On the basis of the traditional mold parts, the present invention newly manufactures fixed mold inserts and movable mold inserts, uses the least mold modification process and the lowest mold processing cost, and directly replaces the dynamic, The fixed mold inserts and movable mold inserts on the fixed mold can be quickly switched, and converted into mass-produced protective net injection products with rebound and cushioning characteristics, without transfer and use of sponge materials, eliminating the need for manual pasting production processes, not only It optimizes the quality of leak-proof and fool-proof for the sponge sticking process, and also reduces the labor intensity of employees. In the present invention, the cushioning claw is provided on the cushioning injection molded parts, so that the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap